Kiloan Console

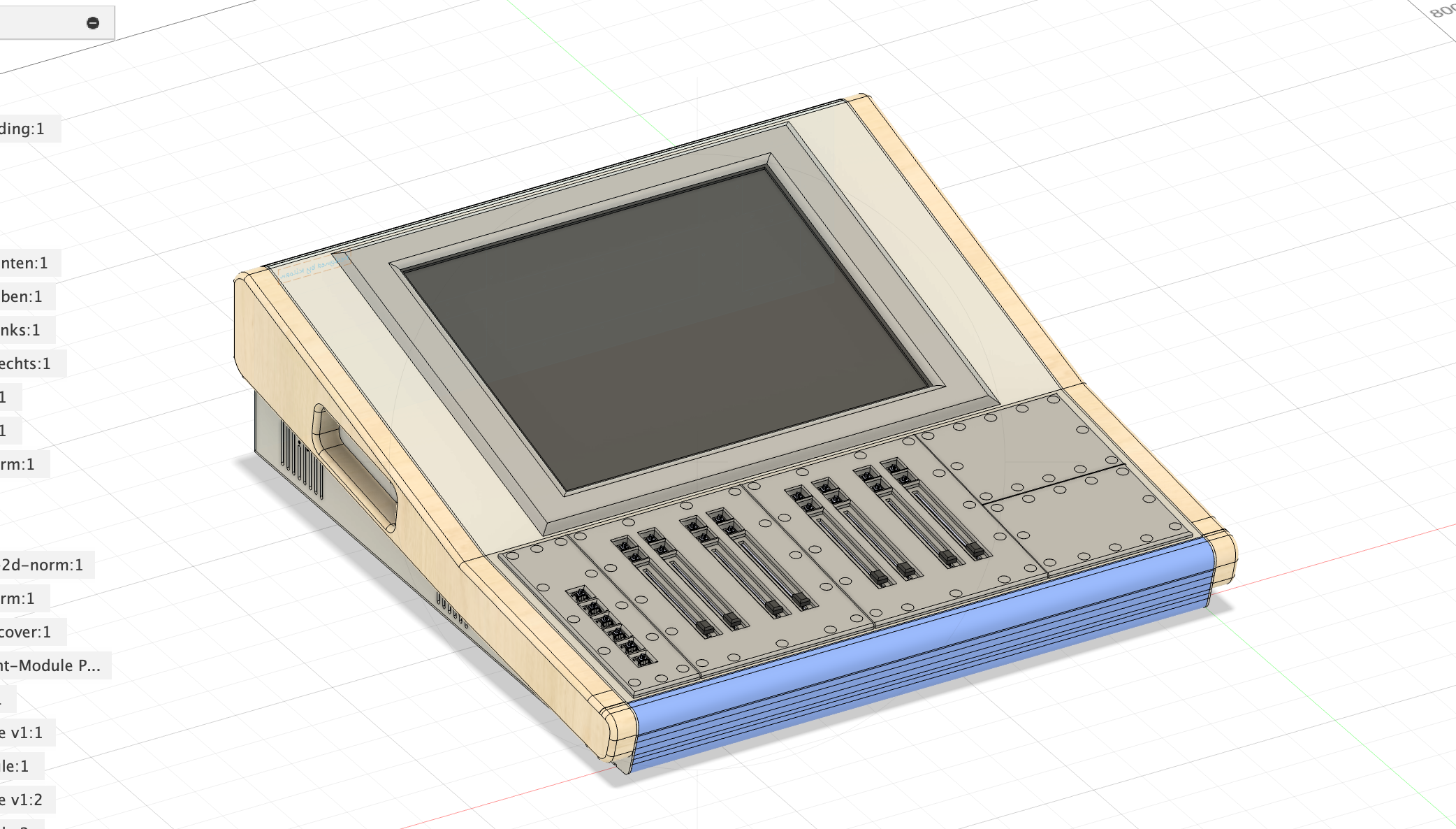

A multifunctional Mixing-Console like Chassis System.

Created by

![]() Kian

Kian

Tier 1

10 views

0 followers

Timeline

![]() Kian

submitted Kiloan Console for review ago

Kian

submitted Kiloan Console for review ago

![]() Kian

added to the journal ago

Kian

added to the journal ago

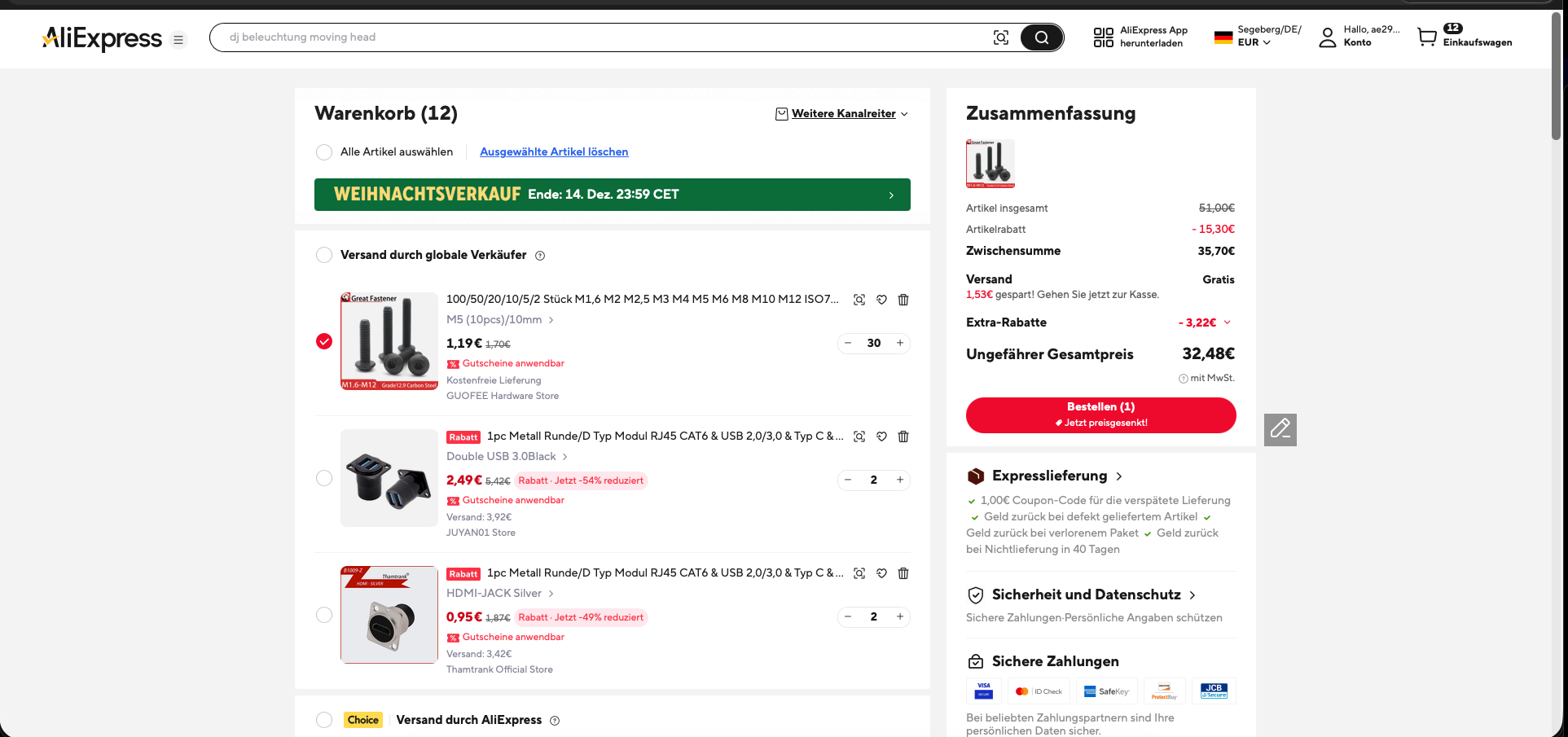

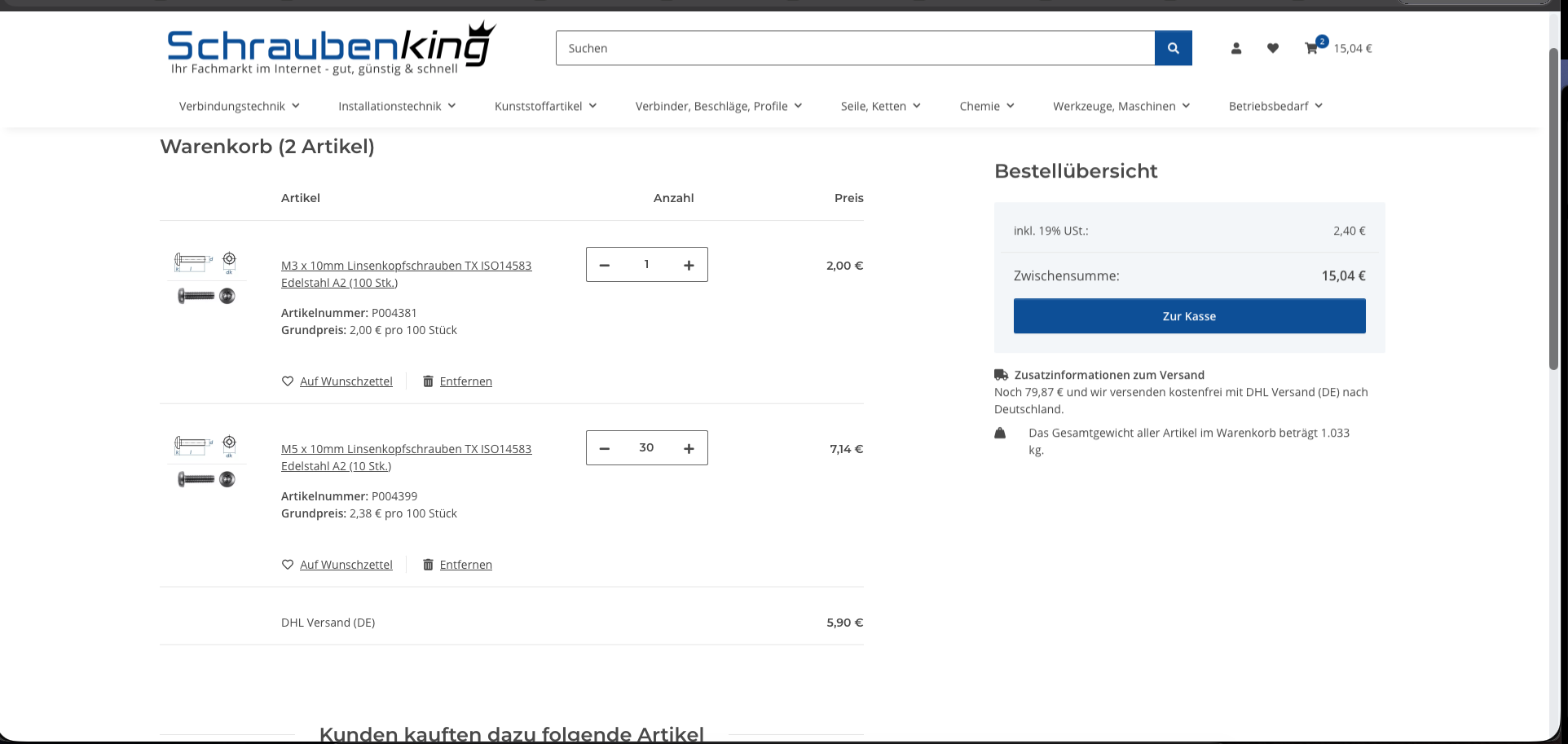

The price problem

As hopefully my last post, I have to address the prices again. You could still get the screws from AliExpress but after a long search, Schrauben-king is significantly cheaper. For almost 300 M5 screws and 100 M3 screws, it comes to a good $32, compared to the nearly $17 at Schrauben-king if I remember correctly, which is much more expensive. The PCBs and aluminum plates are cheapest at JLC, even with shipping. For the small electronics, I used the cheapest components, the slide potentiometers are the cheapest in their size.

I hope this has clarified things a bit, and that my project get accepted!

Another nice picture so I can save this post:

![]() PenguinBoyMo

requested changes for Kiloan Console ago

PenguinBoyMo

requested changes for Kiloan Console ago

Try to reduce shipping cost, and if you can't do that, try to reduce other parts and use temu or AliExpress for cheaper parts

![]() Kian

submitted Kiloan Console for review ago

Kian

submitted Kiloan Console for review ago

![]() Iamalive 🚀

requested changes for Kiloan Console ago

Iamalive 🚀

requested changes for Kiloan Console ago

Hey, you list the total cost of shipping as $264.63, but that doesn't seem to line up with your cart screenshots. Additionally, is EuroPacket the cheapest shipping method for your pcb? There usually should be Global Standard Direct Line.

![]() Kian

submitted Kiloan Console for review ago

Kian

submitted Kiloan Console for review ago

![]() Kian

added to the journal ago

Kian

added to the journal ago

A problem, a Solution

I tried using the M5 screws from AliExpress, but after almost two hours of searching, the cheapest ones I found were €32 in total for 300 screws, and that was just for the M5 screws. Even in previous projects, ordering from Schraubenking was always the cheaper option because they ship locally and in large quantities (300 pieces). And in my opinion, that's the most important thing: always go for the cheapest option without sacrificing quality.

![]() funkeudo

requested changes for Kiloan Console ago

funkeudo

requested changes for Kiloan Console ago

Hey! Your cart screenshots only add up to $250, yet you requested a $400 grant - also could you try to source your screws from AliExpress if possible? Additionally, you mentioned sheet metal - is it possible to use 3d-printed PETG or another cheaper material instead? CNC-machined sheet metal gets quite expensive quite quickly. I love your project, though!!

![]() Kian

submitted Kiloan Console for review ago

Kian

submitted Kiloan Console for review ago

![]() Kian

added to the journal ago

Kian

added to the journal ago

Shipping time!

Today I finally had time to export all the individual files. Yesterday, I made the first sketches for the individual parts that will be produced from sheet metal, and of course, that took far too long, like everything I attempt. Today I sorted everything and created the readme file. Tomorrow, I'll just create the BOM file, since I need the dollar amounts for the sheet metal for that, and I won't get those until I receive confirmation from JLCCNC. Hopefully, I'll get them tomorrow.

In conclusion, I have to say how much fun this project has been, and that I can finally realize this dream after so long. Thank you so much!

![]() Kian

added to the journal ago

Kian

added to the journal ago

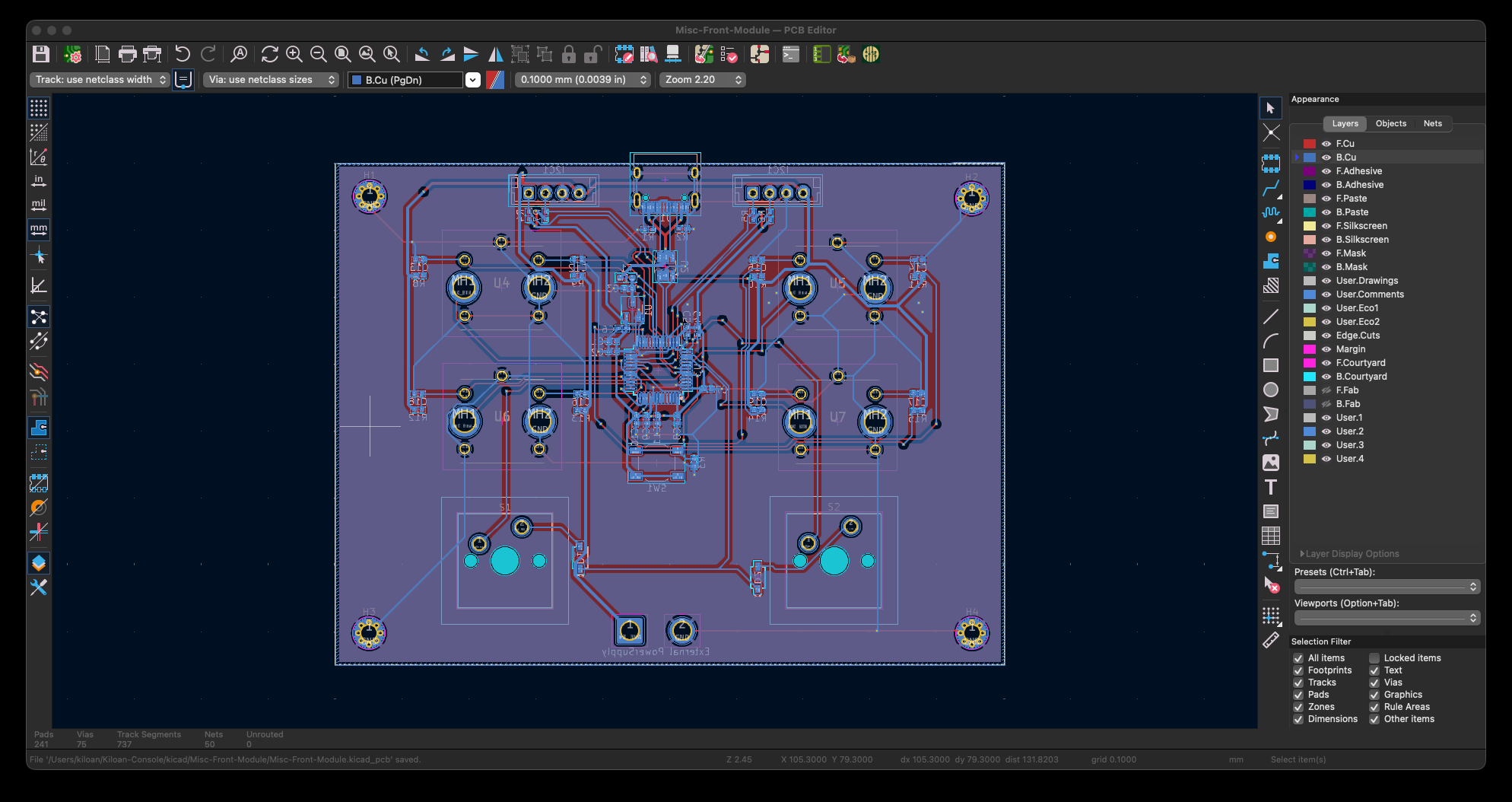

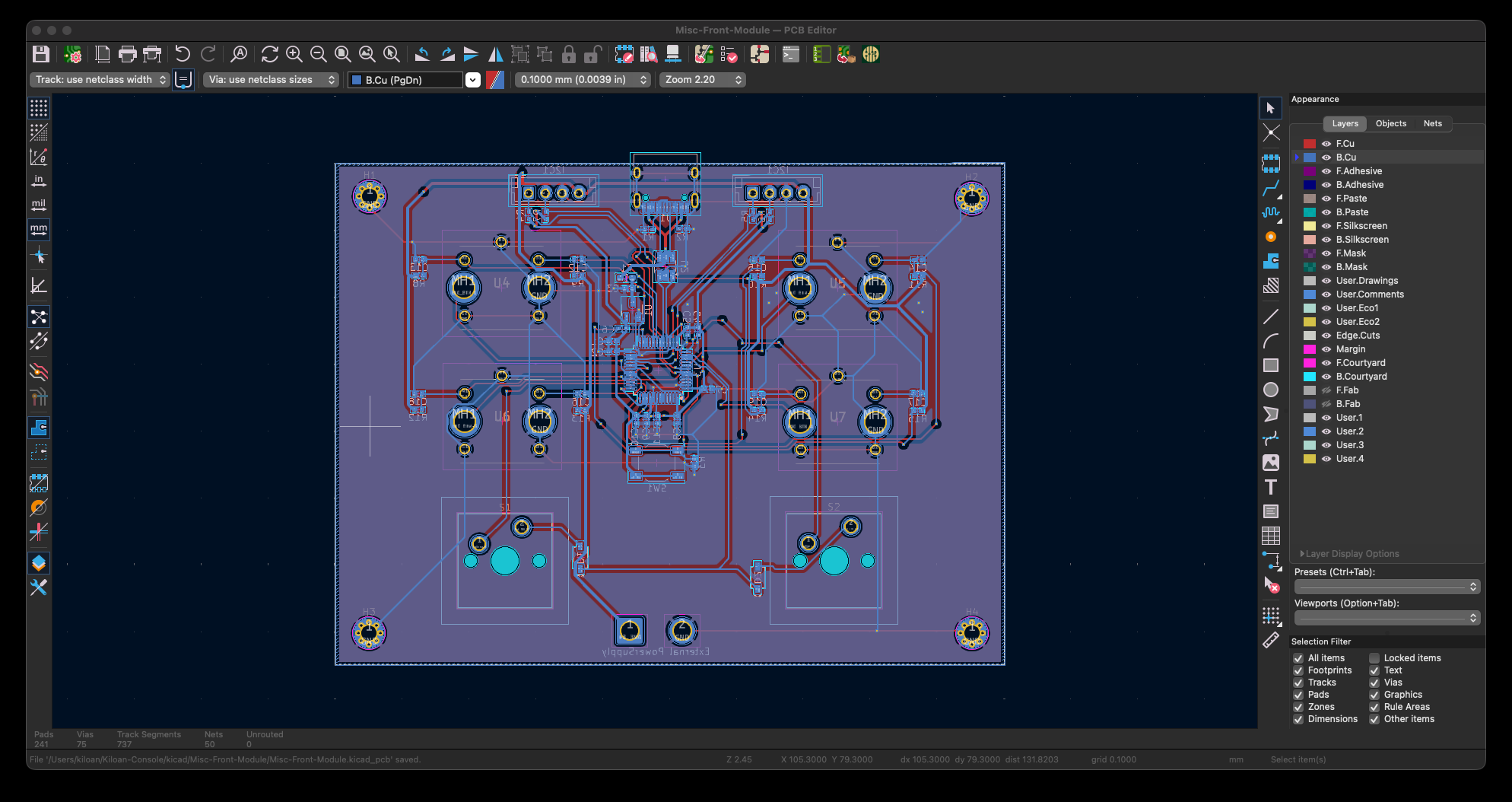

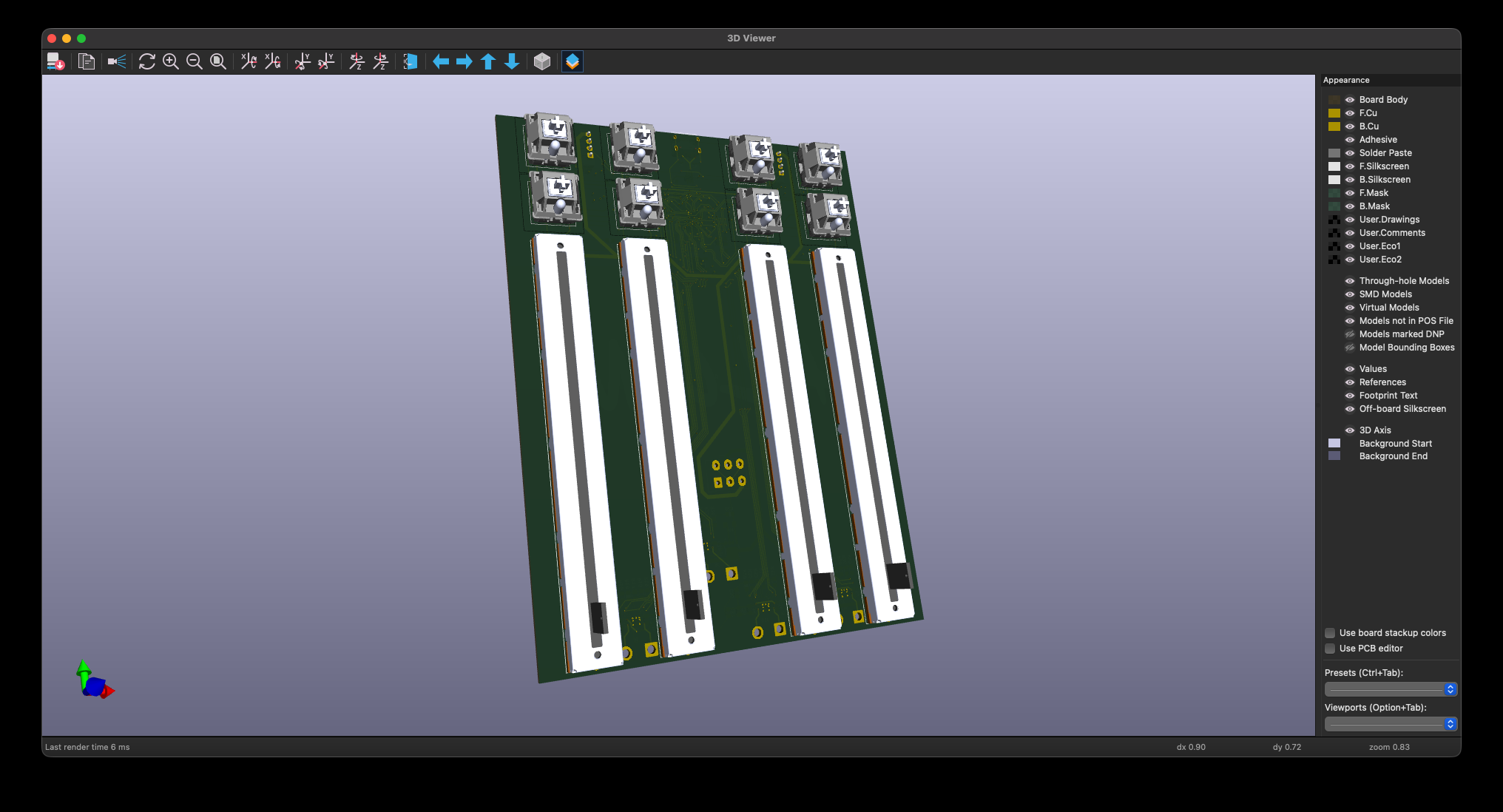

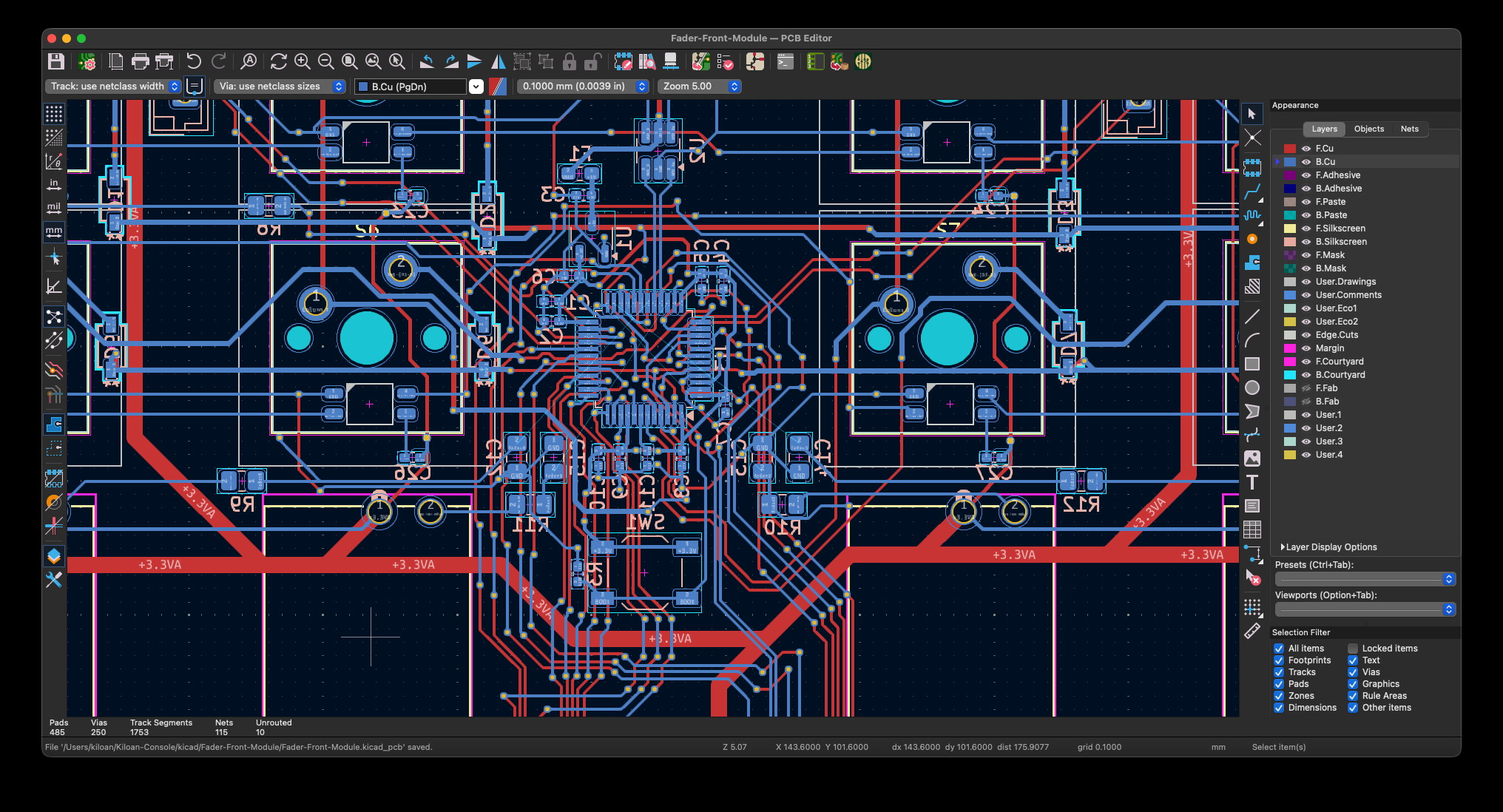

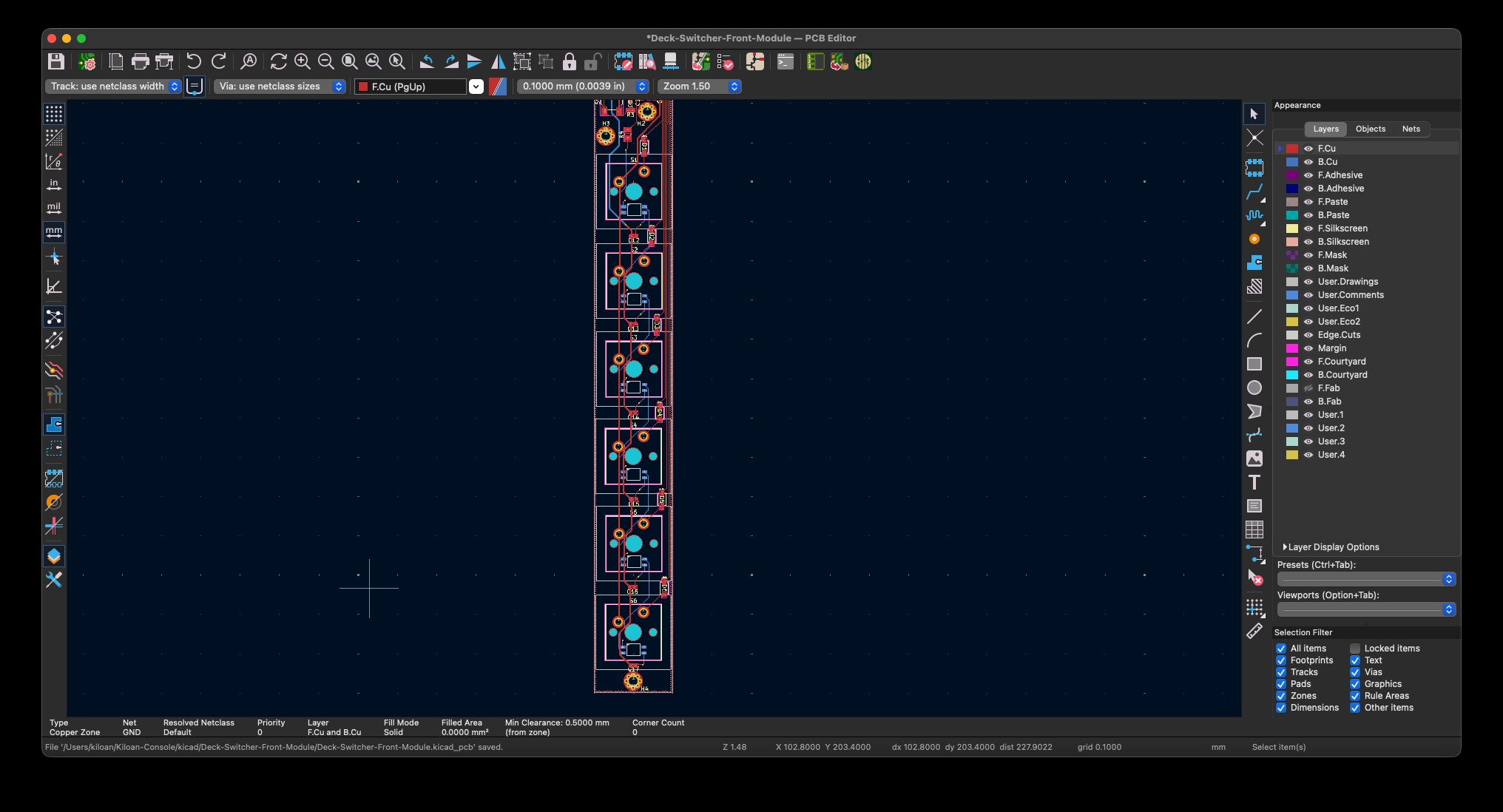

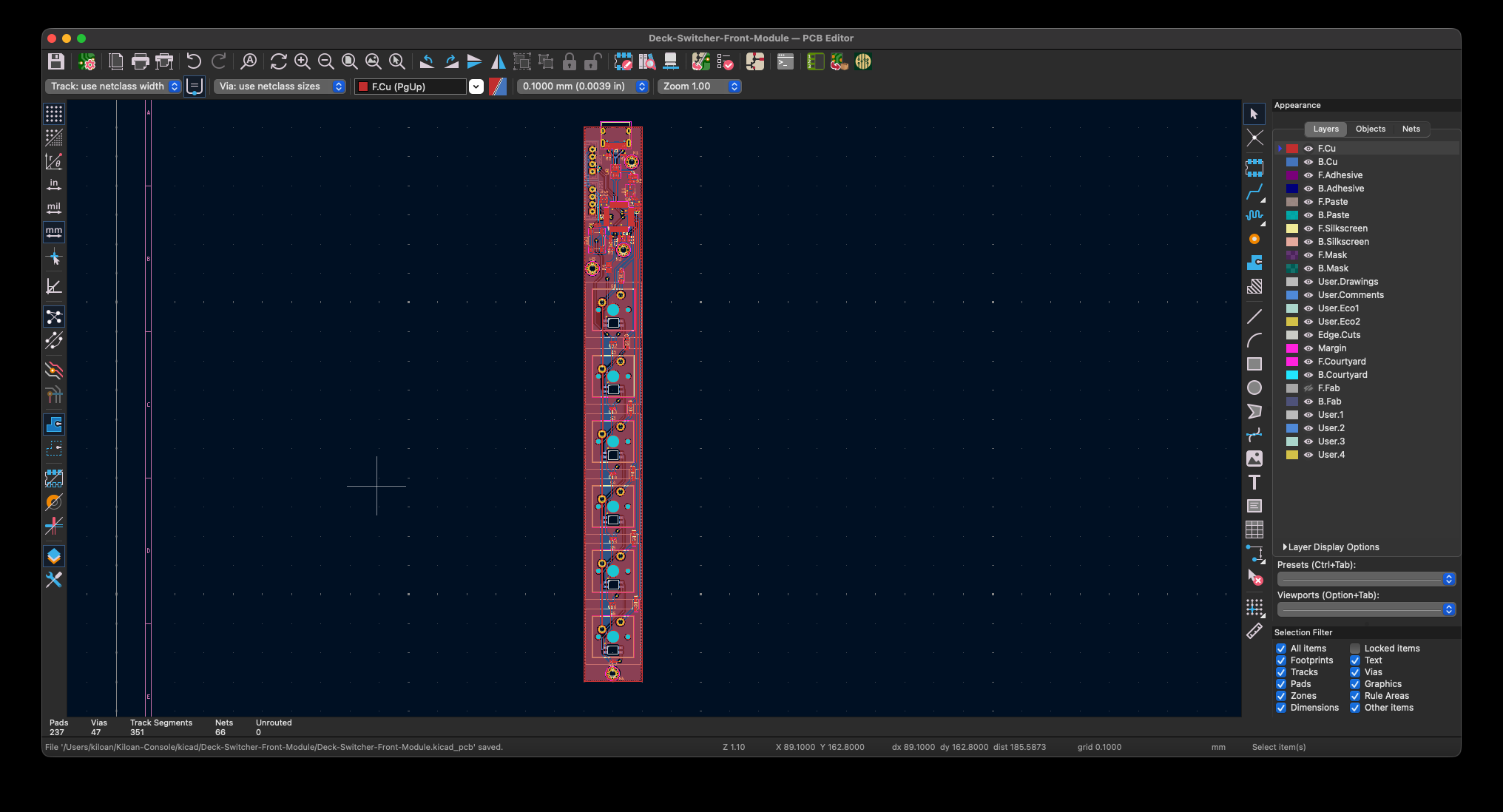

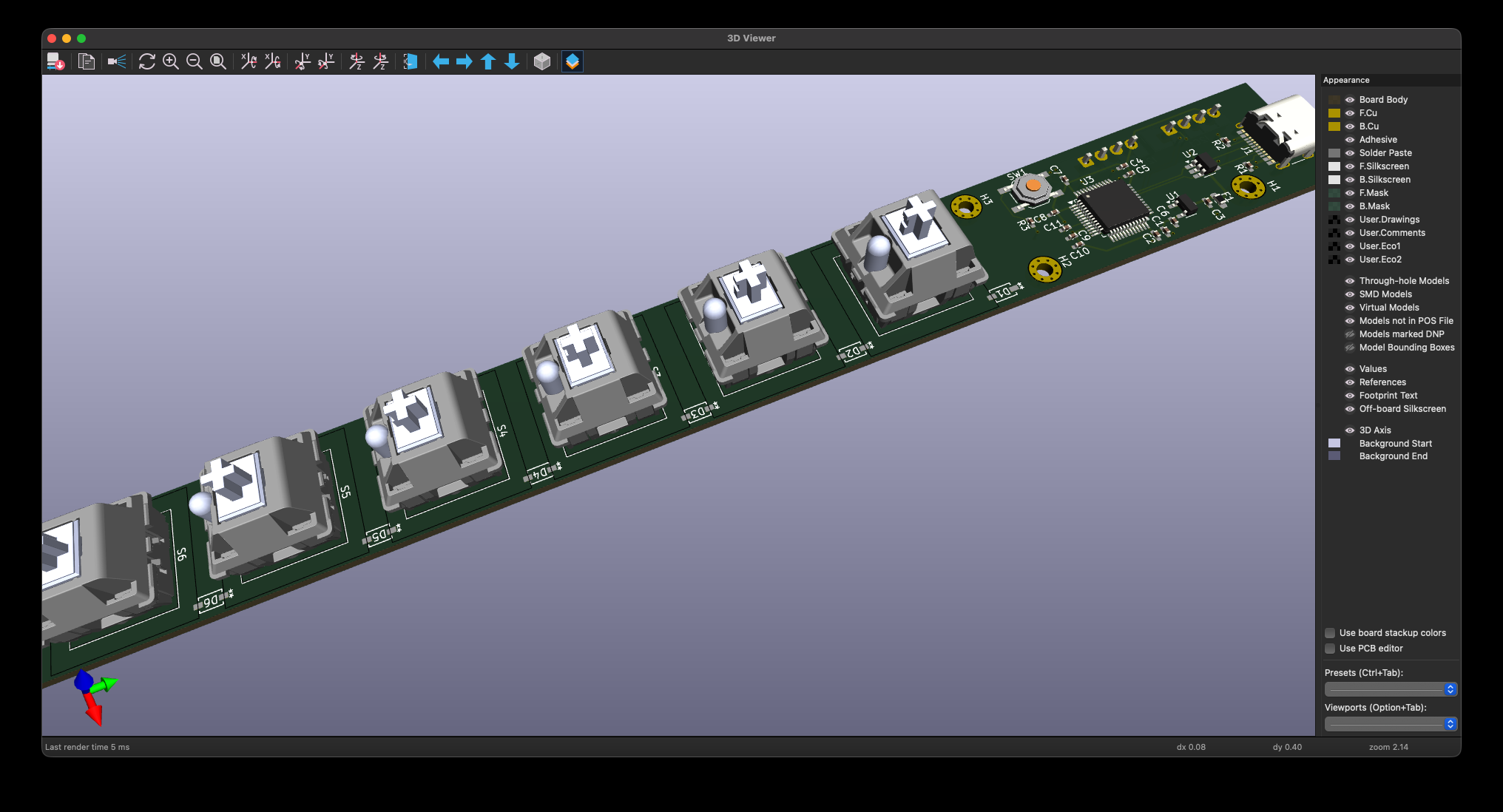

Last PCB + Module

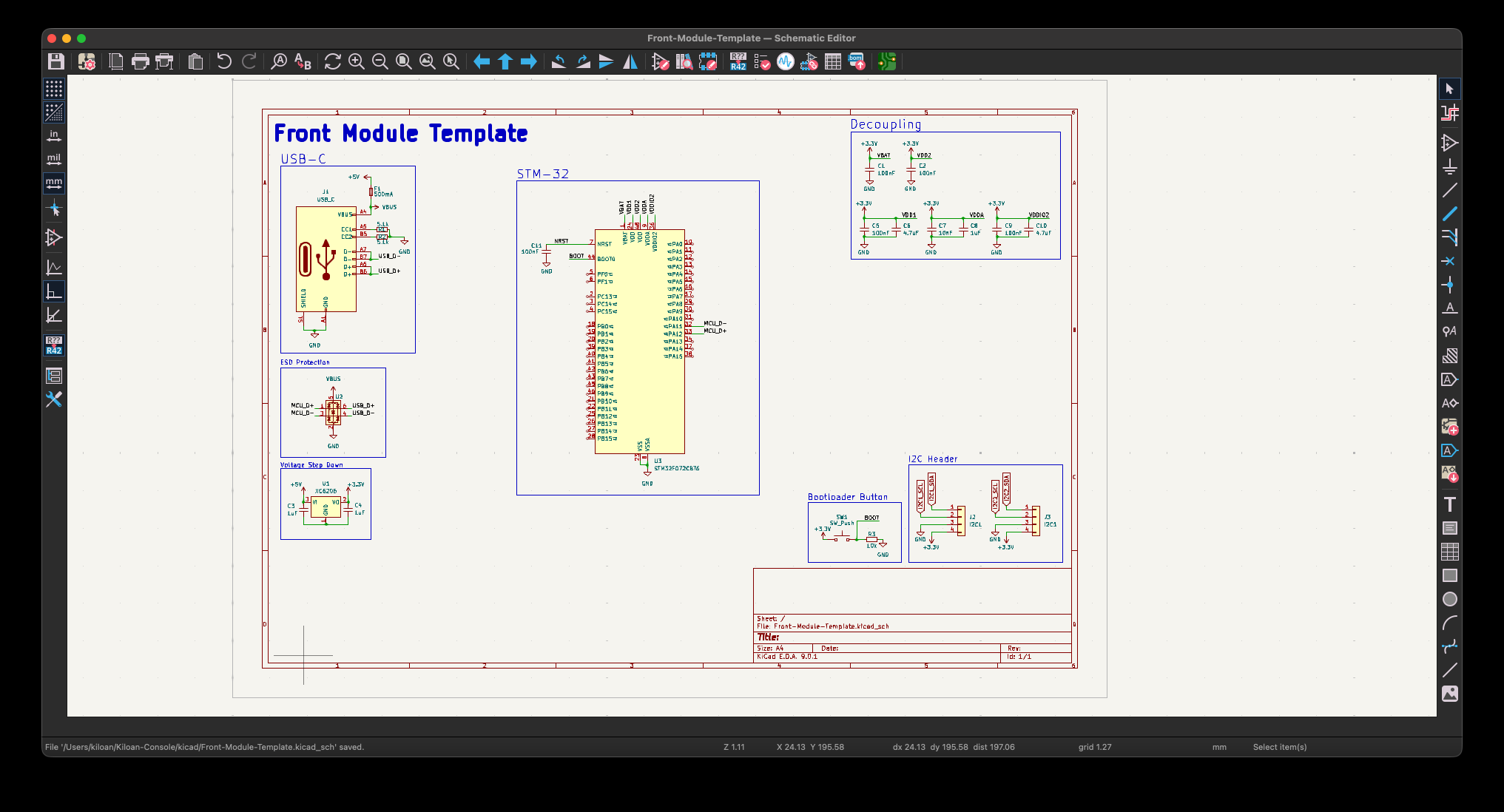

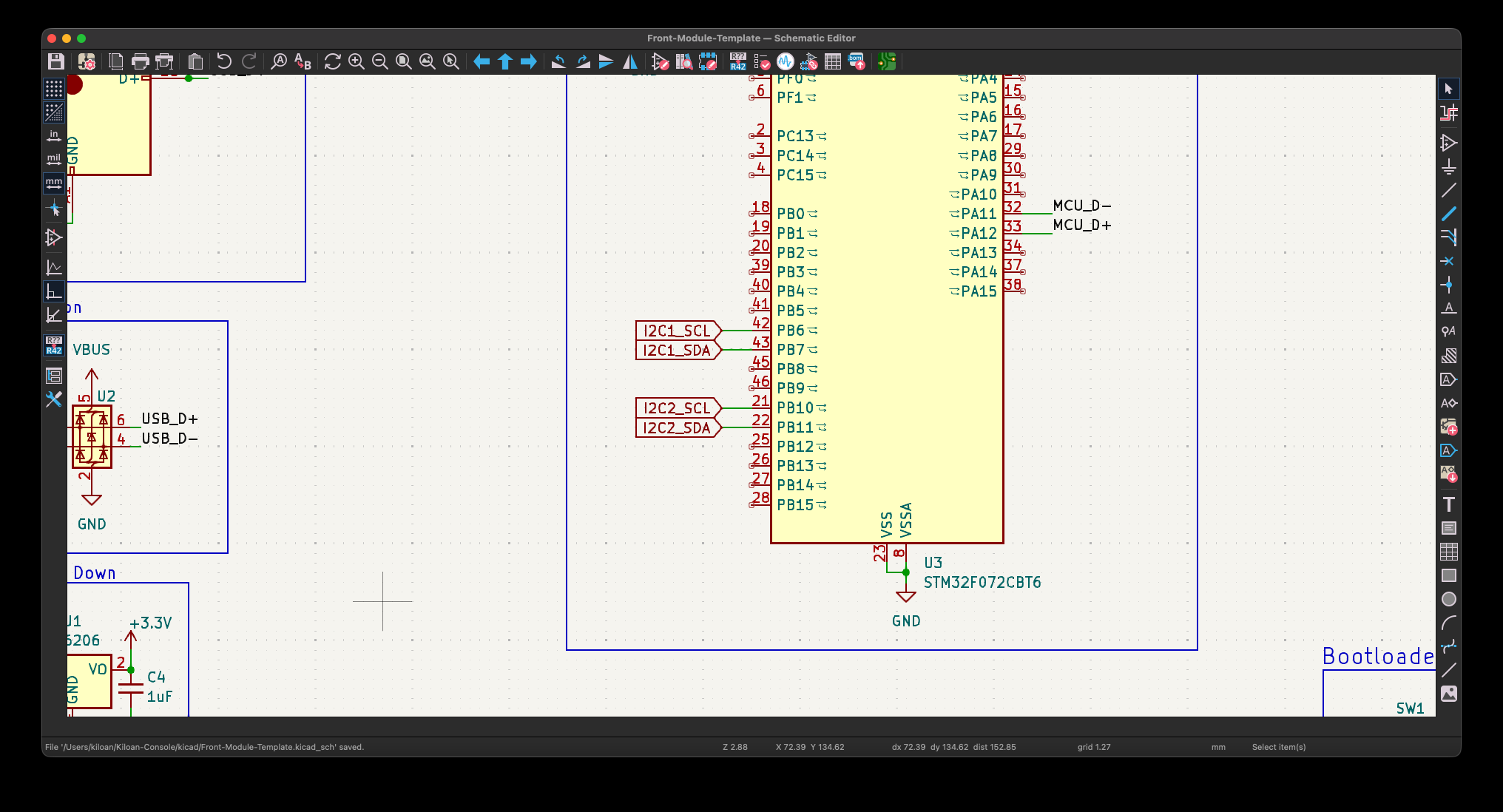

Today I started with the front module template for the third time and made a small PCB, nothing exciting, just two cheap encoders I found on LCSC and two regular switches without LEDs, so I just have switches without having to use expensive LEDs again. Here are the schematics:

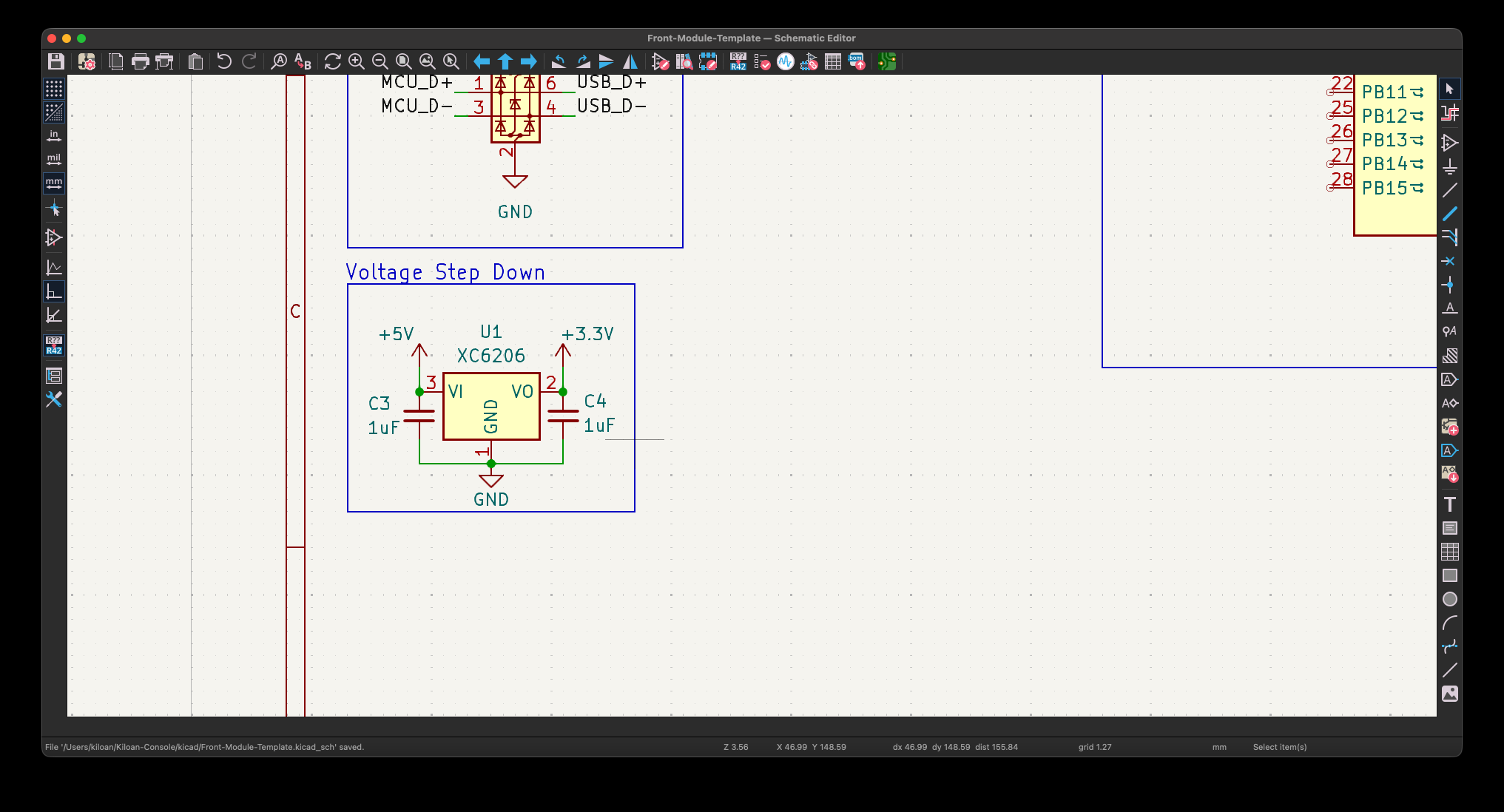

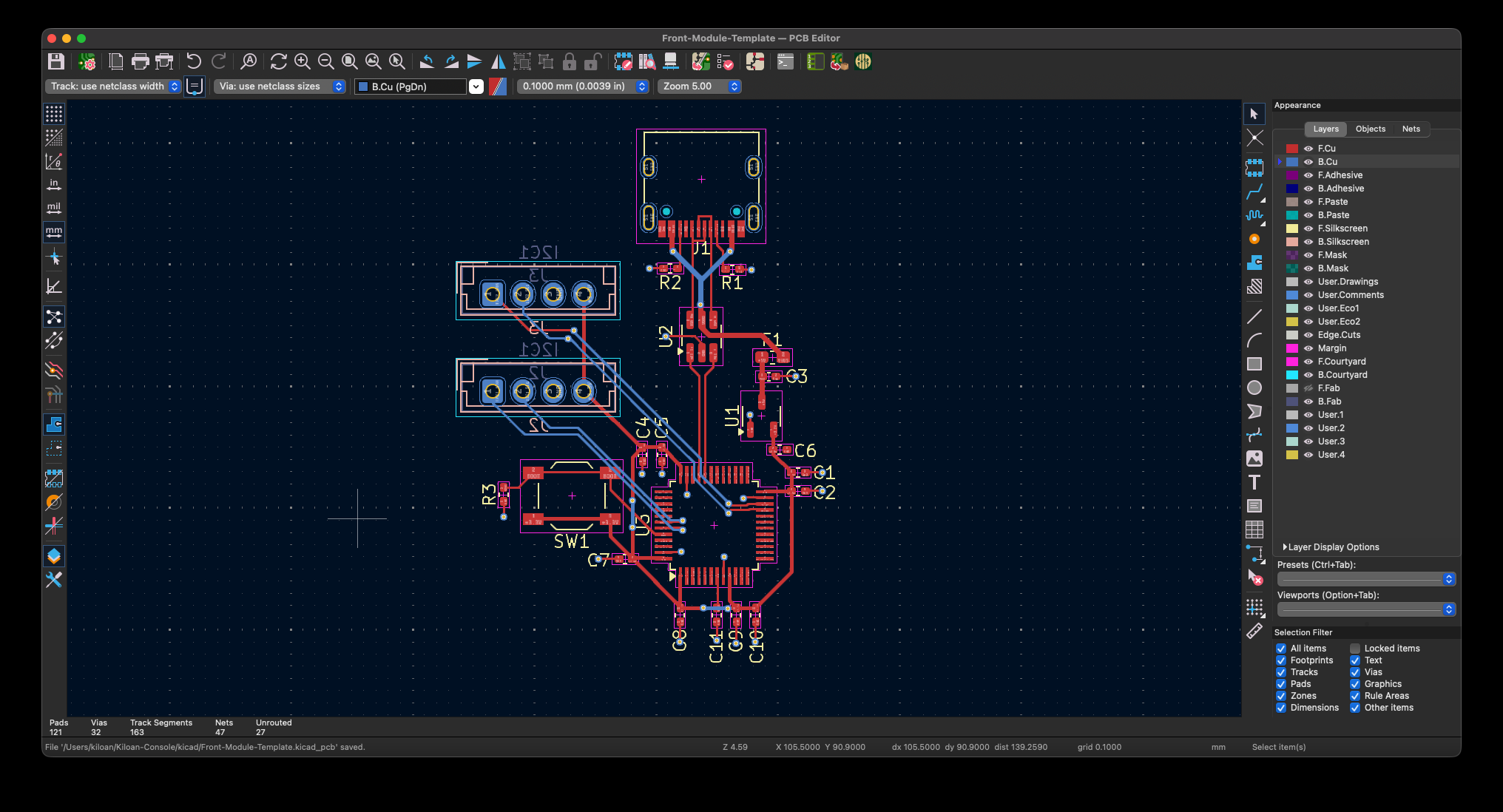

Then I routed everything. I did the important stuff like the I2C lines and everything for the processor, as well as the component placement. Then, for the first time, I just started the autorouter and let it do its thing (never again, that's really ugly). So if this PCB doesn't work, I'll blame the autorouter. But since it's all analog signals, it shouldn't be too bad with the traces from the autorouter.

.png)

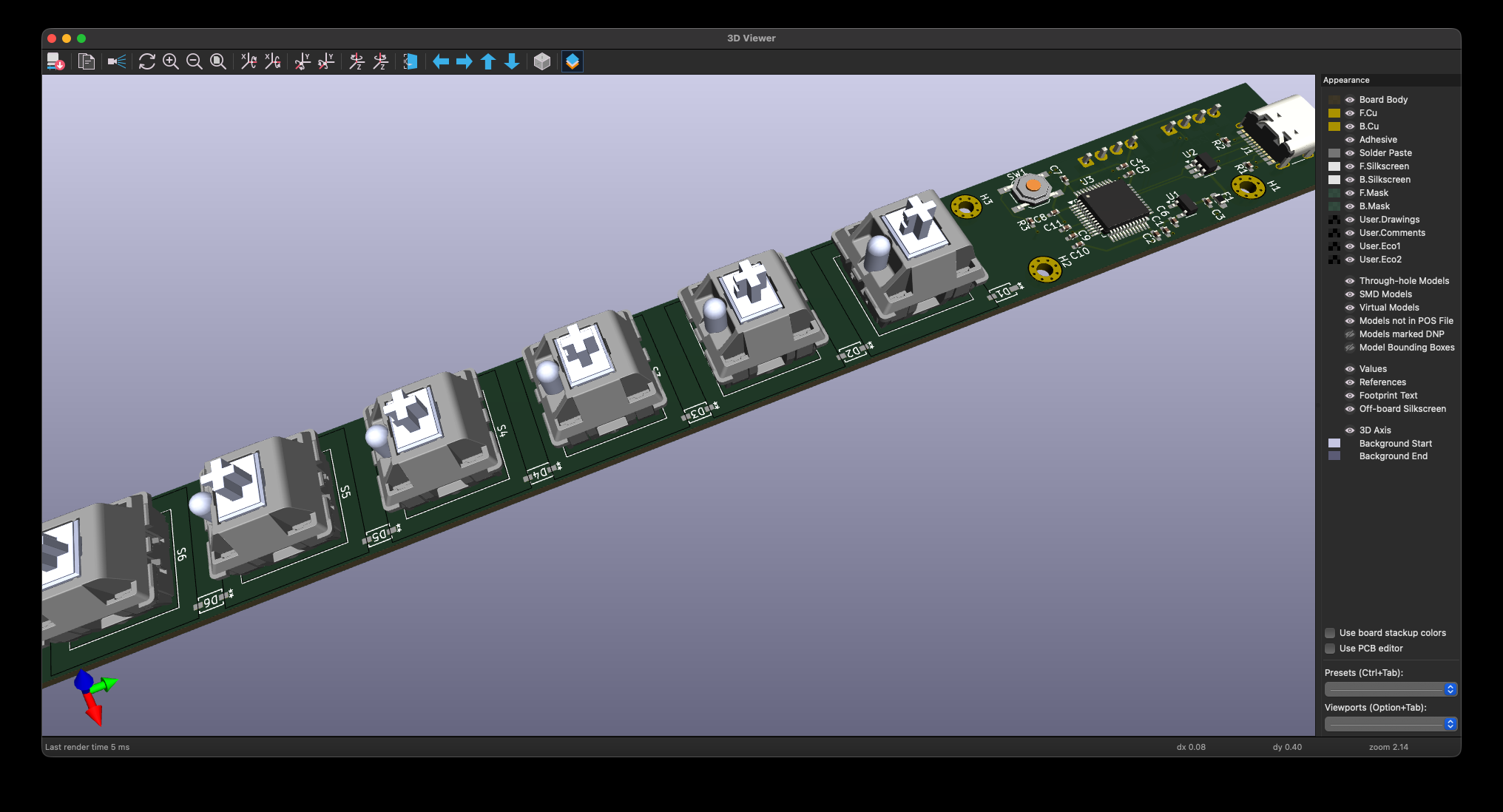

Here is the finished PCB in the 3D viewer.

.png)

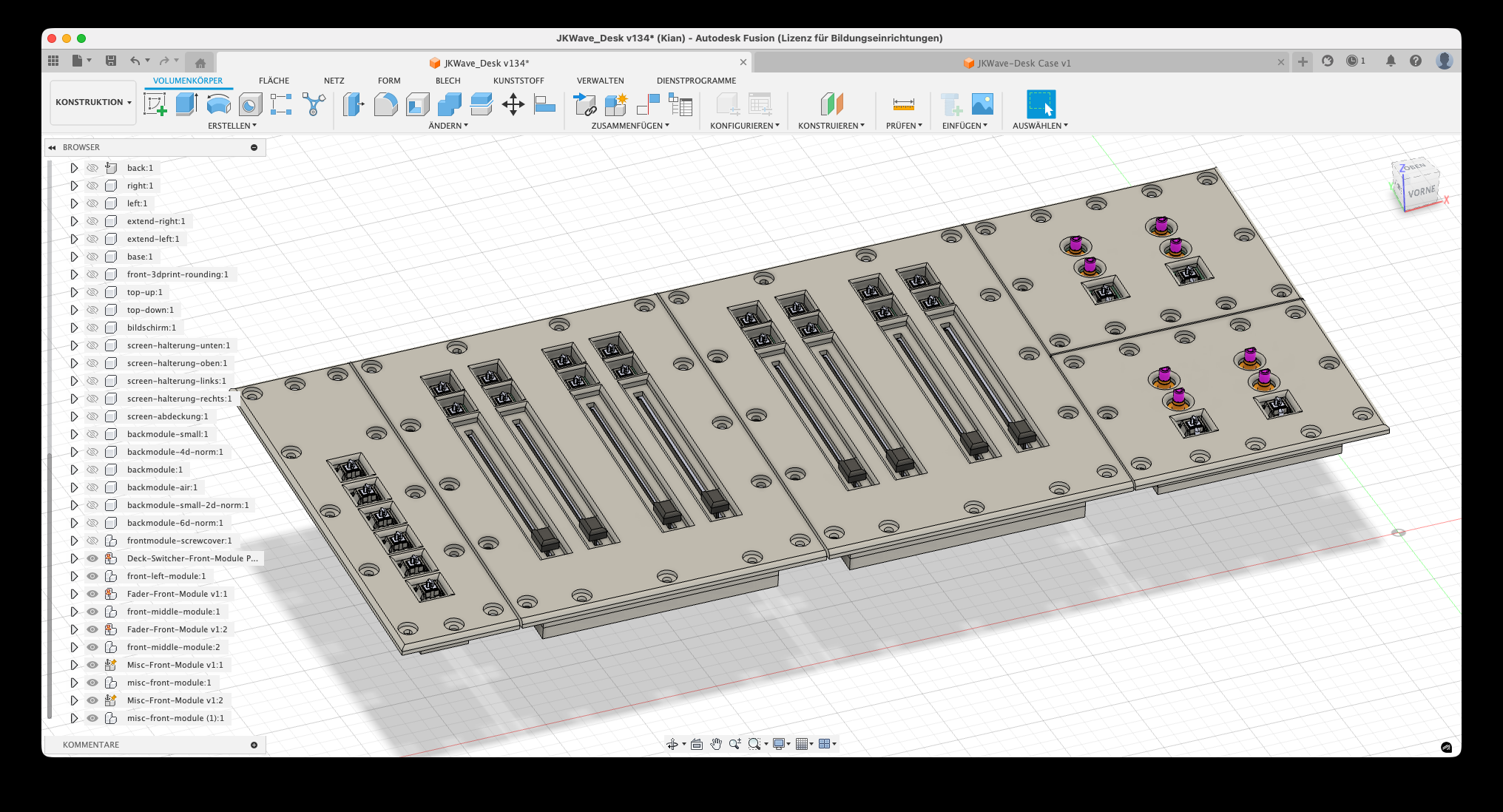

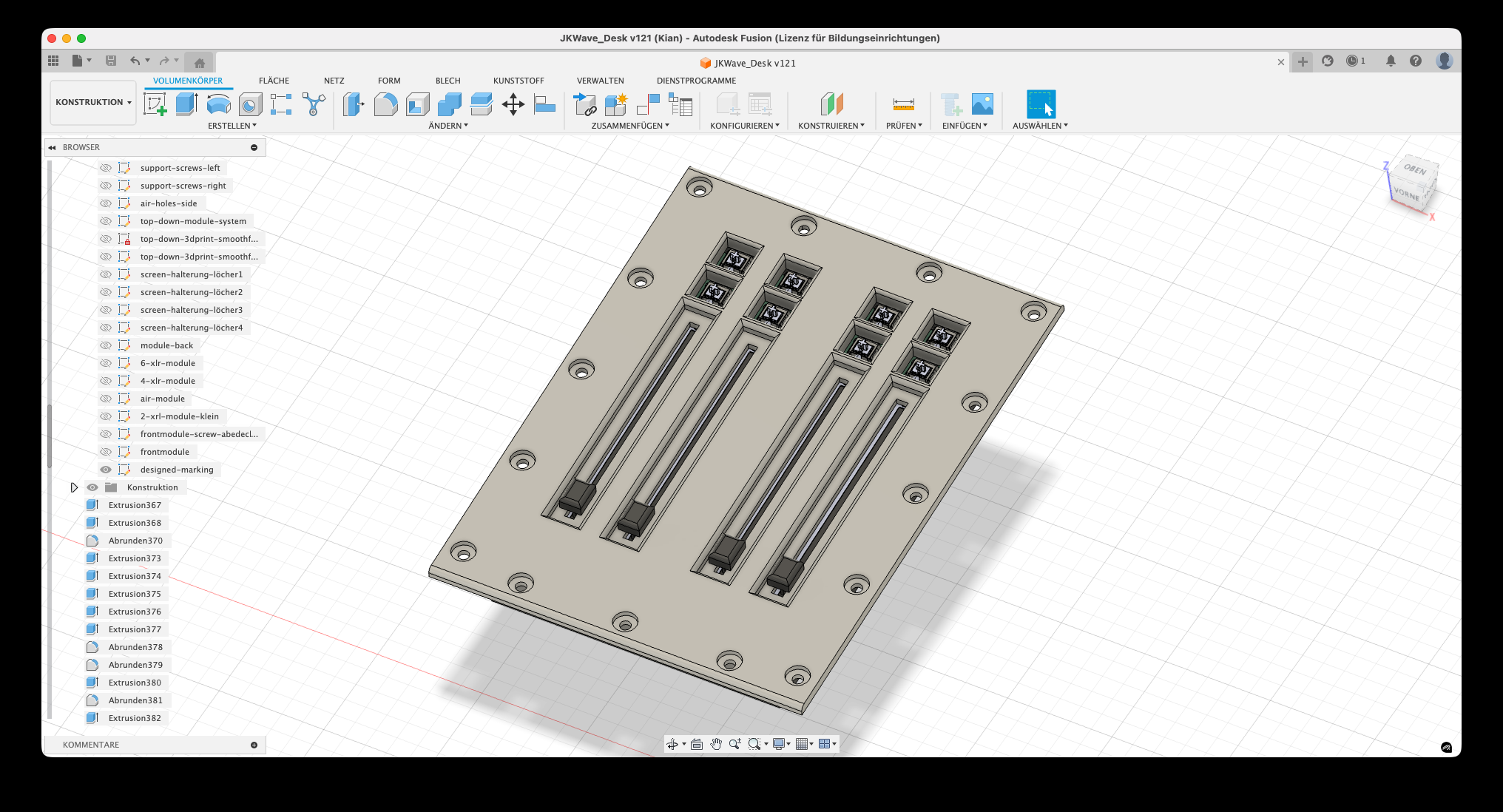

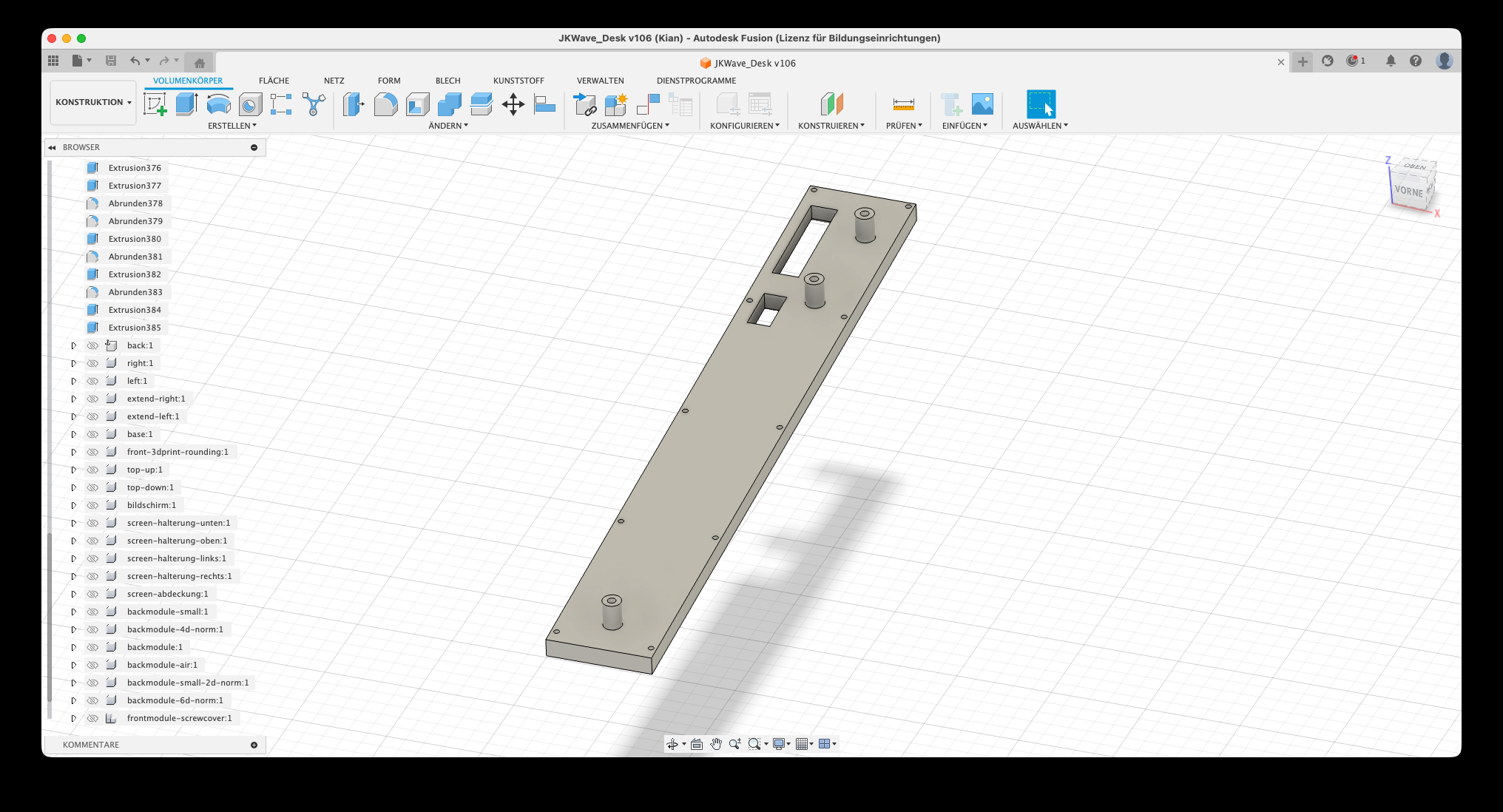

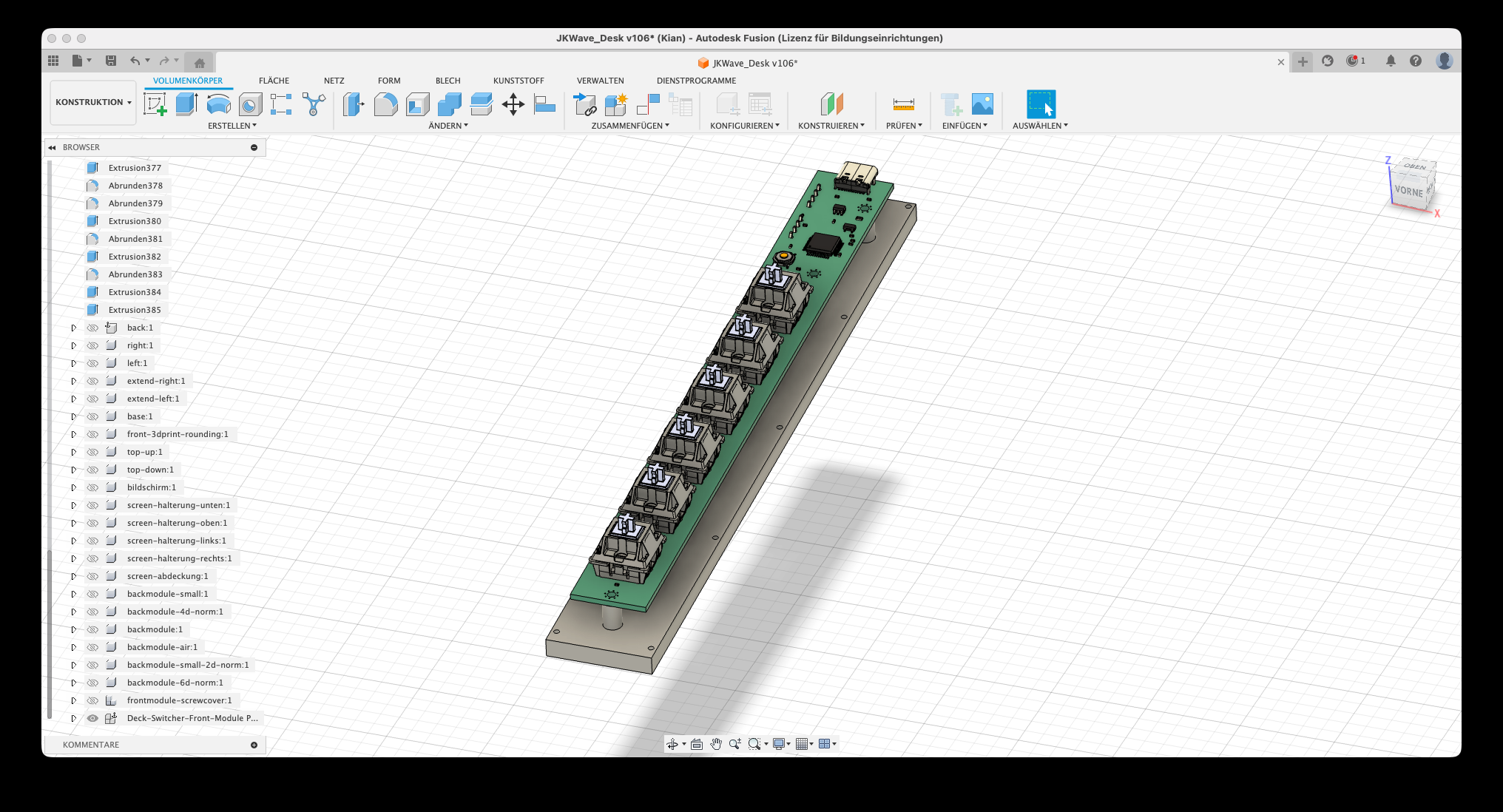

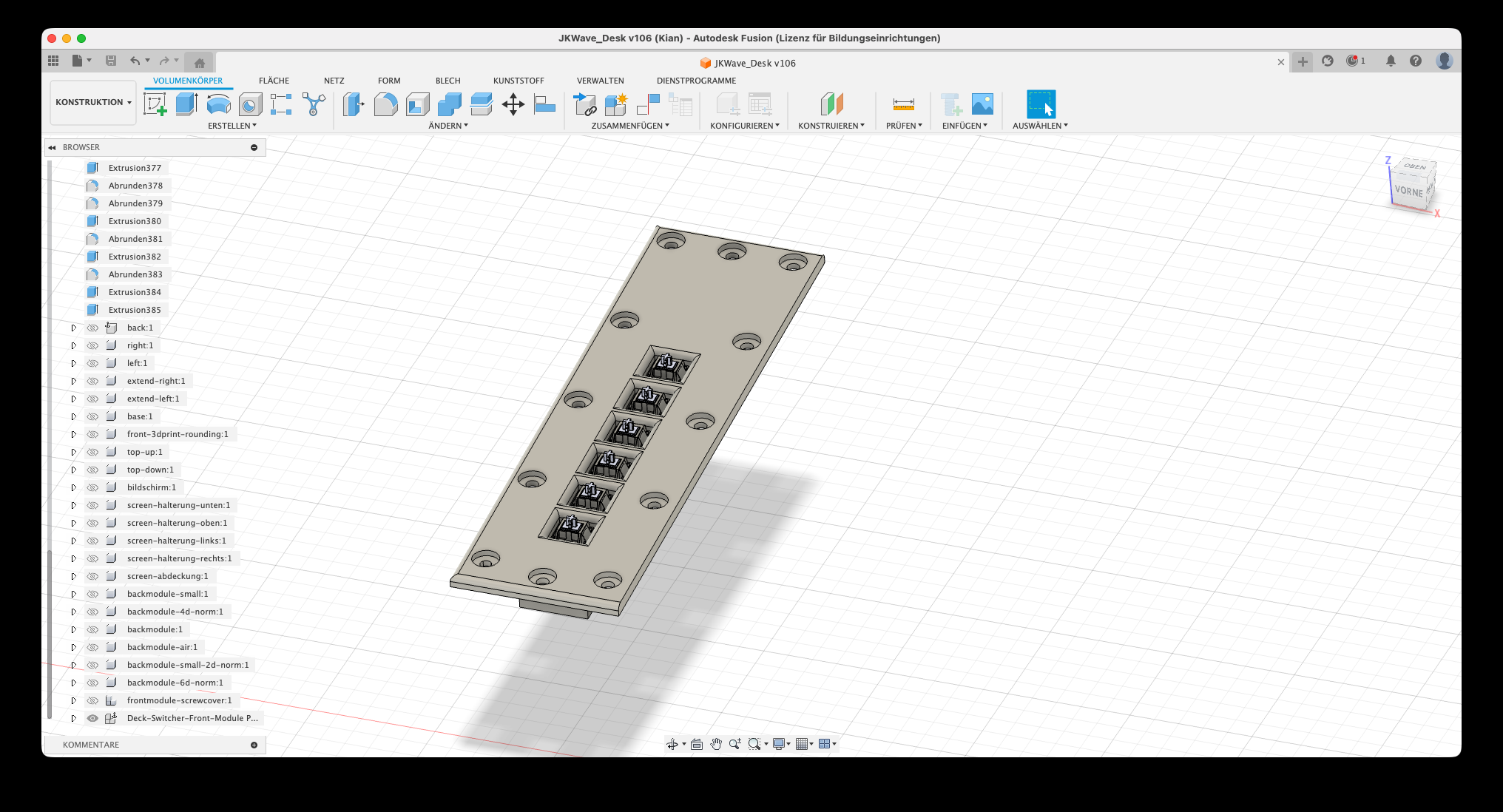

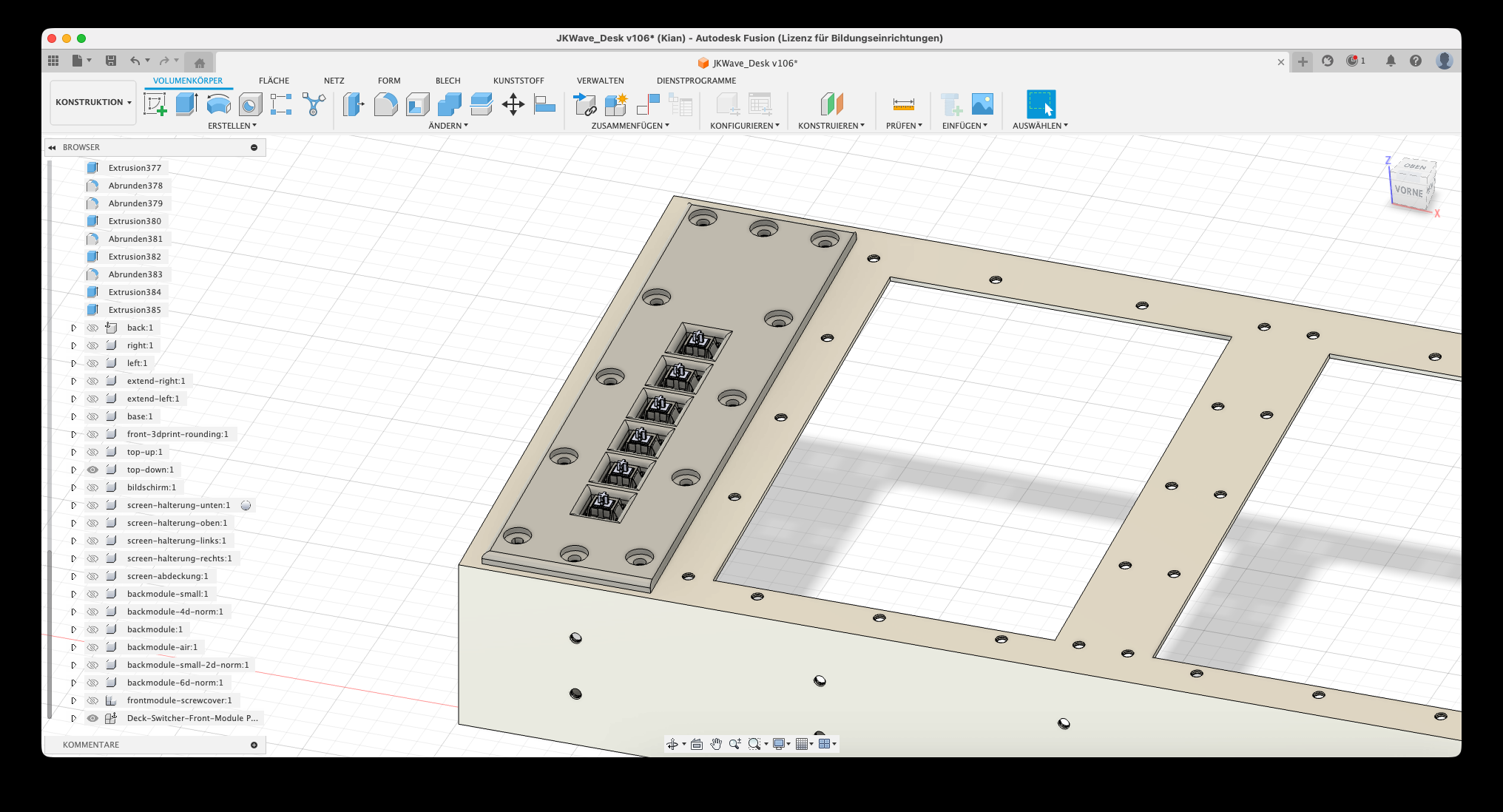

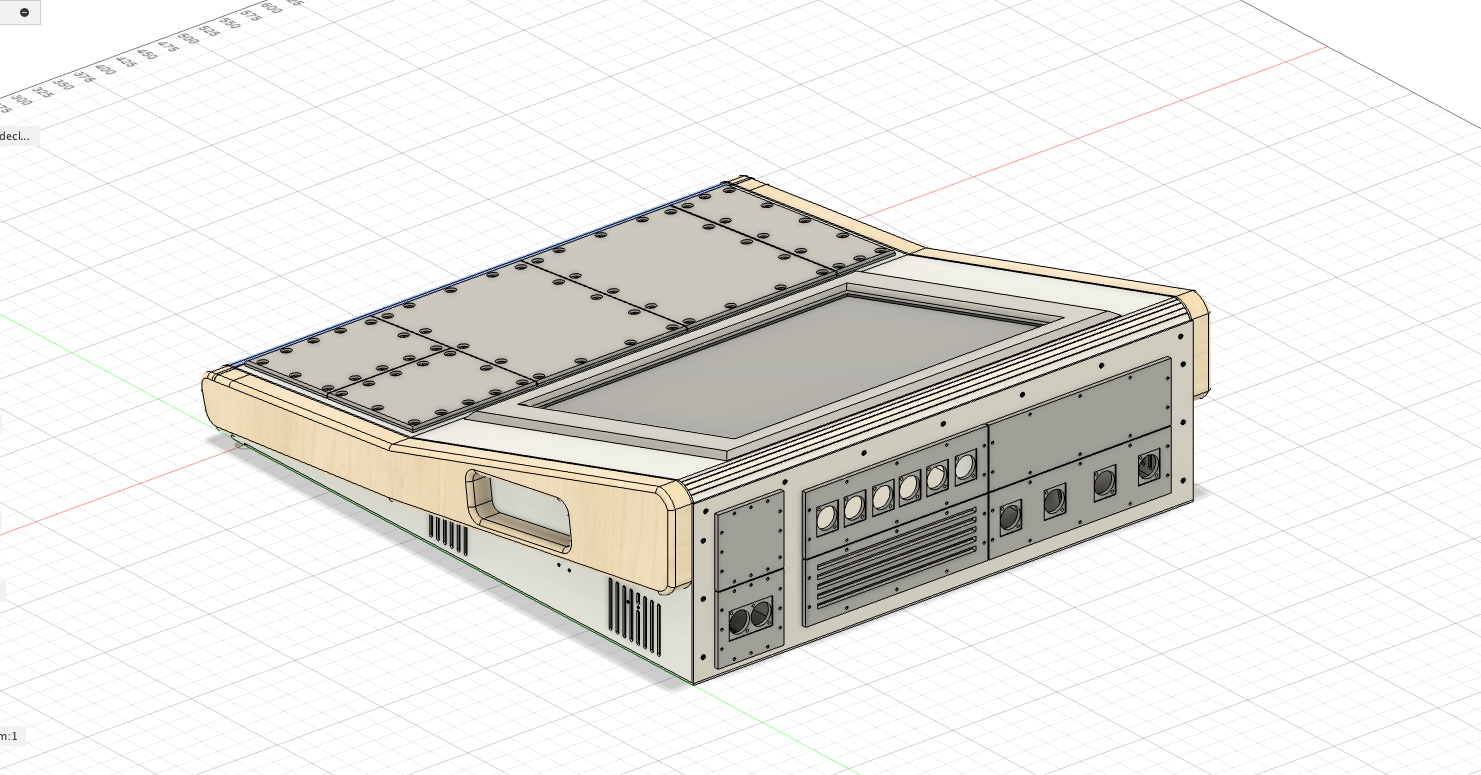

And here are all the modules fully modeled in Fusion 360:

![]() Kian

added to the journal ago

Kian

added to the journal ago

Some plans for the future of this project.

I actually wanted to finish the front modules today, but hopefully the last small PCB will be done tomorrow. For the side with the two stacked modules, I'm planning rotary encoders to control various things, and maybe a few switches.

Once that's finished, I'll consider the project complete. I'll still do some minor things like laser marking and a few improvements to the 3D-printed components. Then the project will be shipped.

In hindsight, I'm annoyed that I did so much of the electronics right away. Maybe I could have consulted with someone and separated the front PCBs. I feel like I'm way over budget, and unfortunately, I can't finance all the components myself. That's why I participated in Blueprint in the first place—because this program is so great for young hobbyists who don't just have $400 lying around to build a project.

Many thanks to the organizers, helpers, and of course, the entire Hackclub!

And here's a nice picture so I can save it here :-)

![]() Kian

added to the journal ago

Kian

added to the journal ago

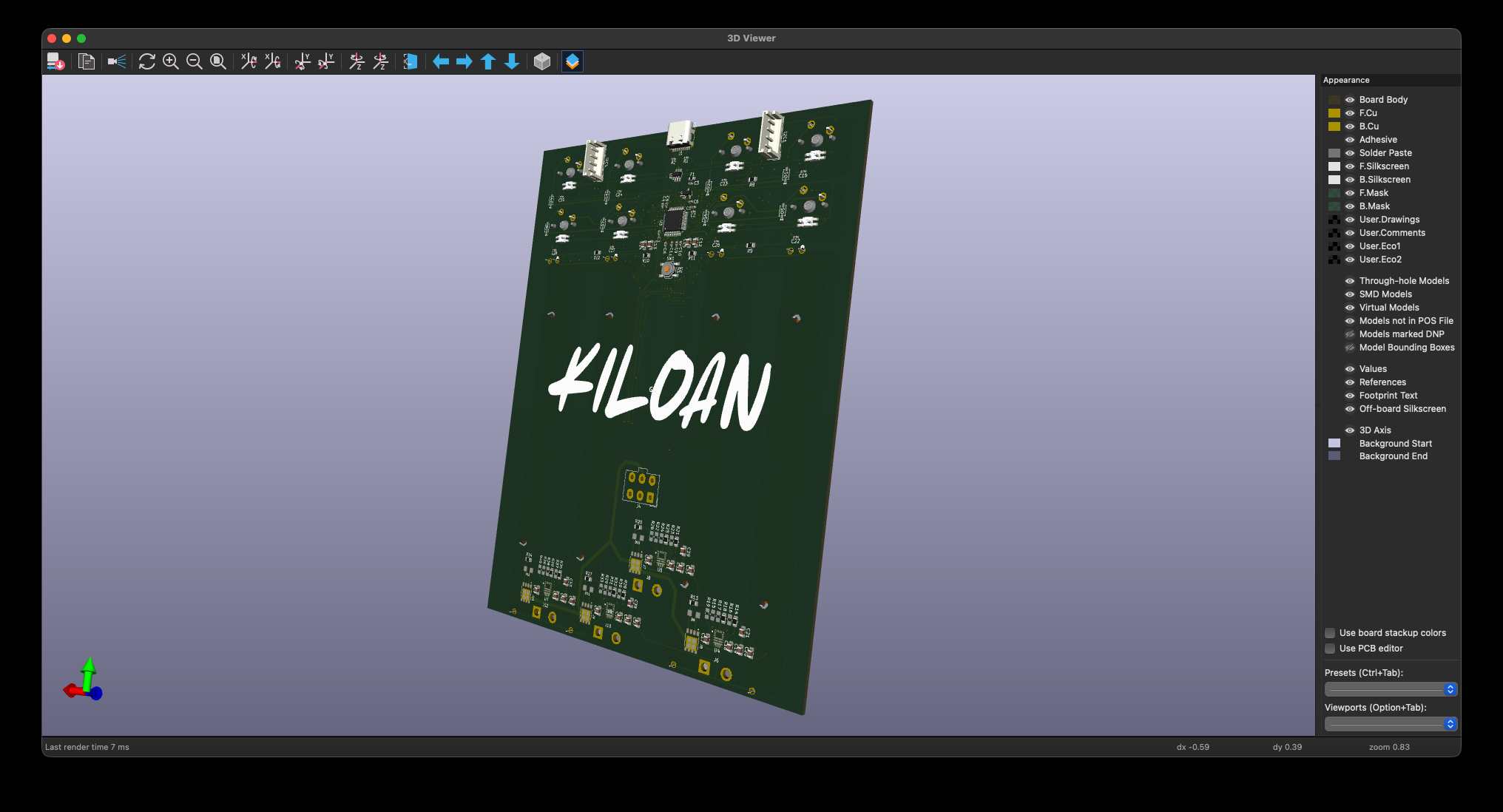

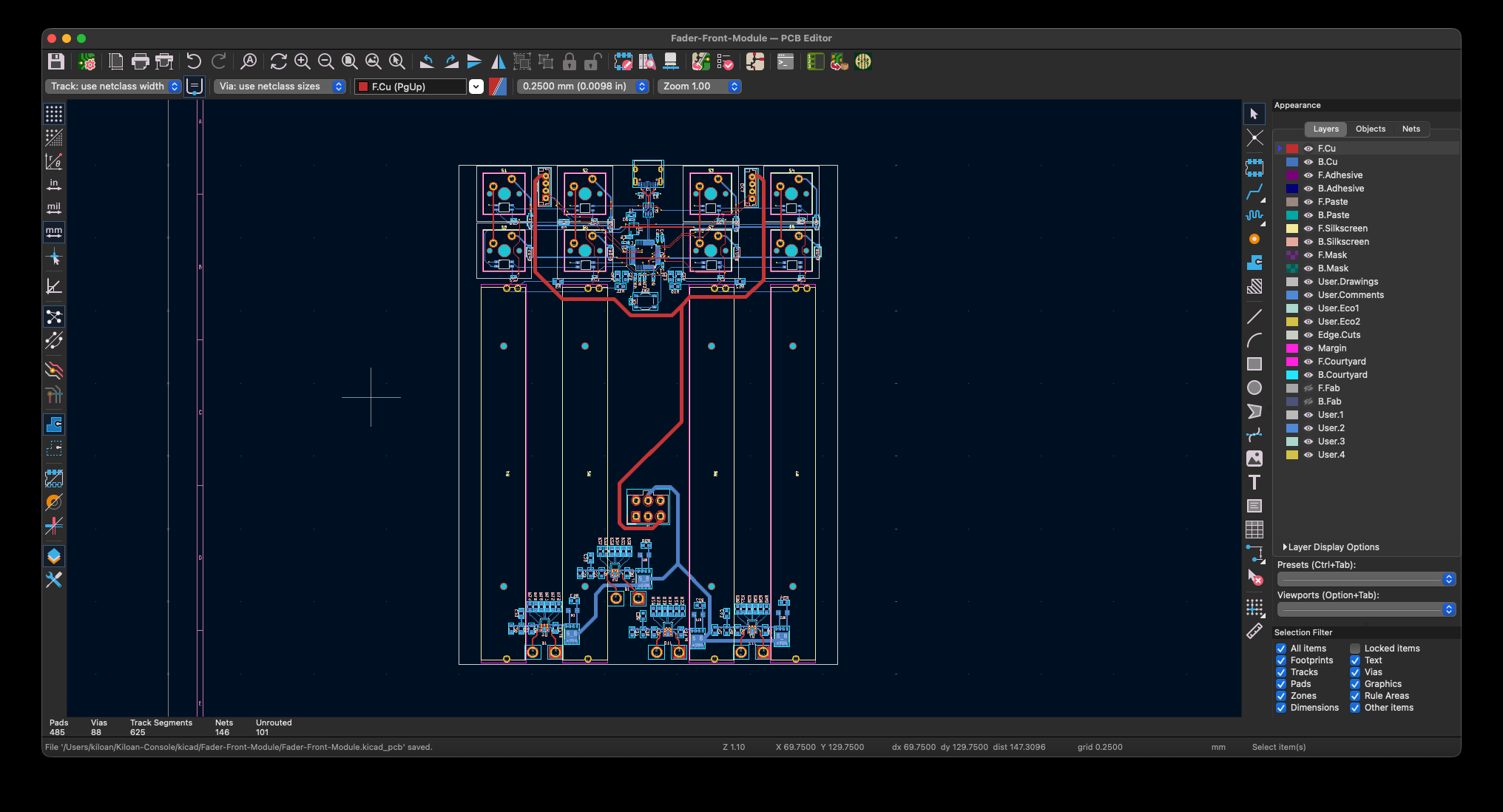

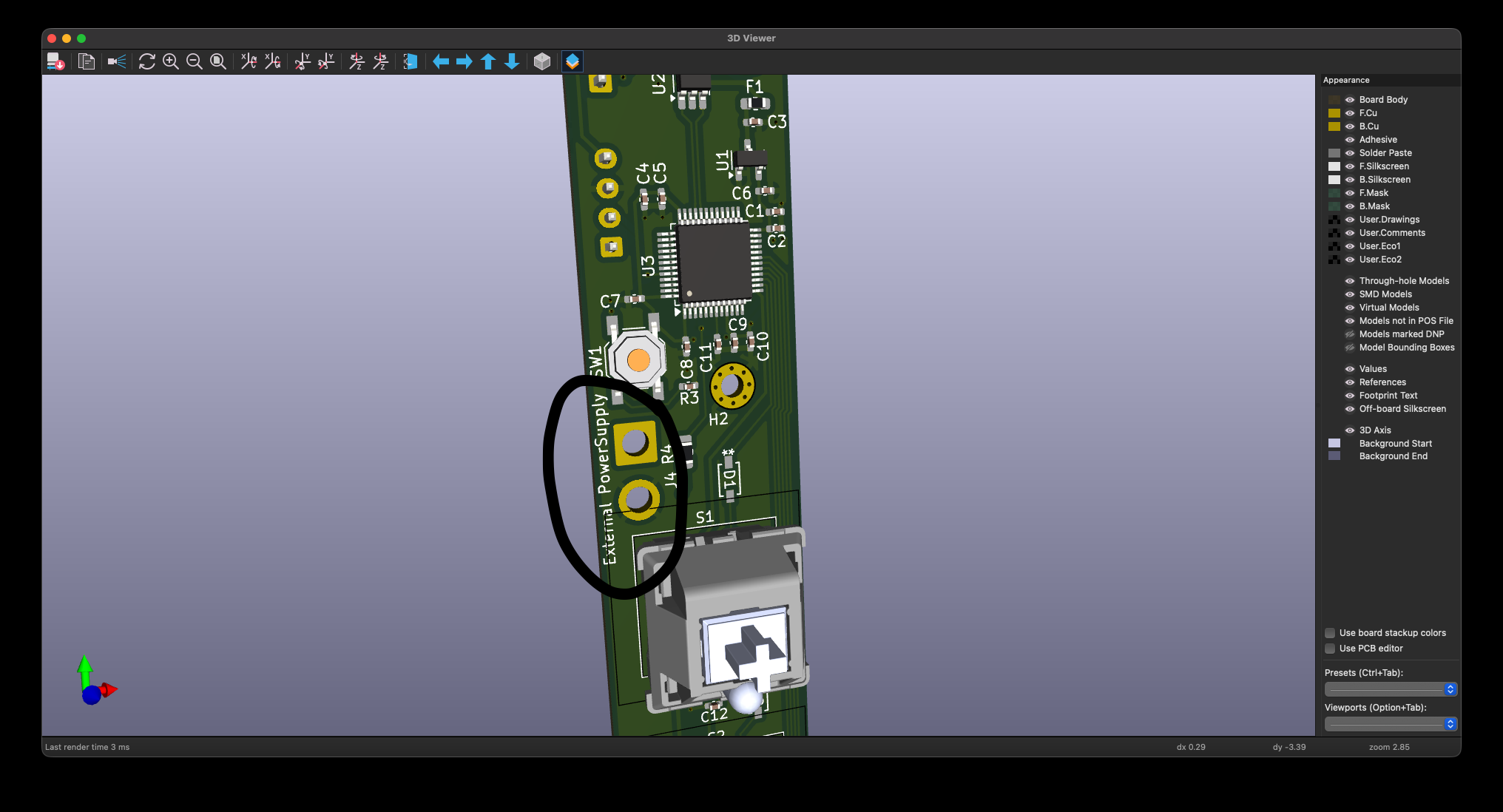

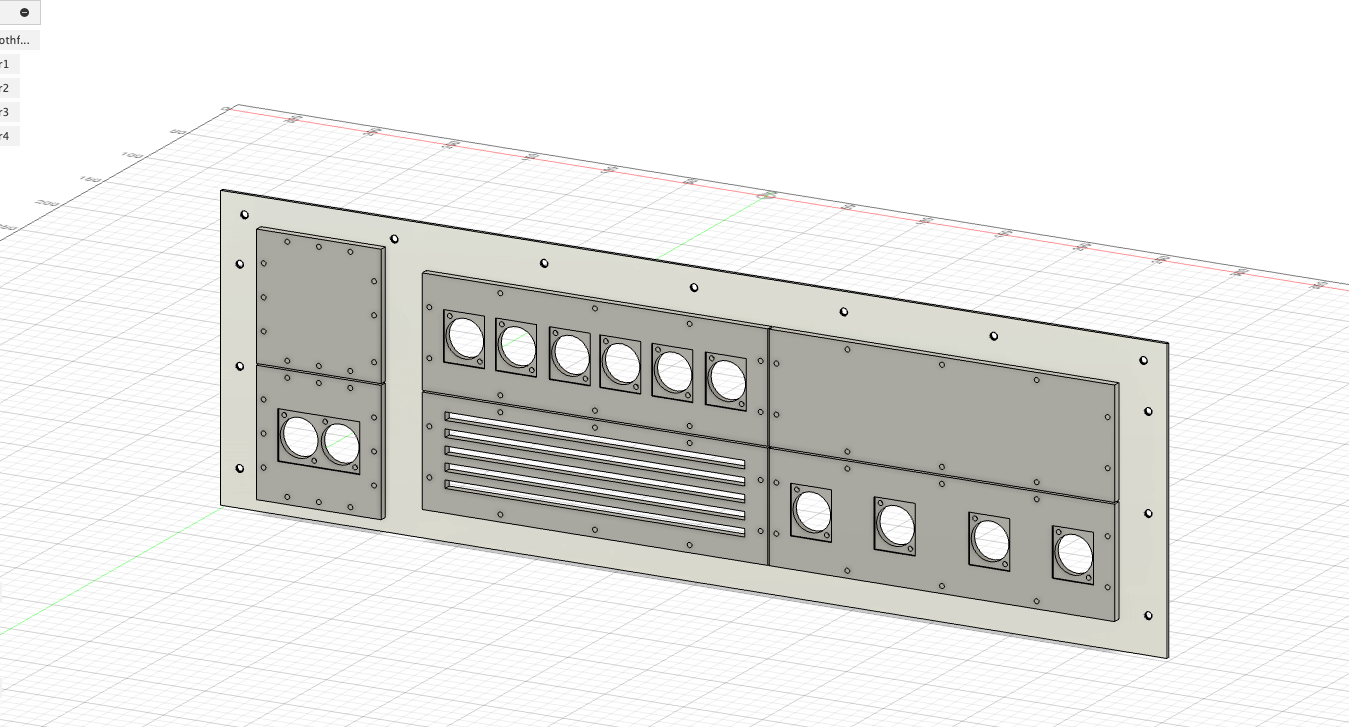

finally finished with the big module

So, the most complicated PCB is finished. I'll just show a few photos of the process here and write more about it later, today really wore me out.

.png)

Since there's so much space on the back, of course there's plenty more room for a Logo.

Here you can see the circuit board from the front, I'm a little proud of myself.

.png)

Then, of course, the module was modeled in fusion360.

And here is the current panel with the three completed modules.

Edit: I forgot to add pull-ups to the i2c headers. I've added that to all three PCBs now.

![]() Kian

added to the journal ago

Kian

added to the journal ago

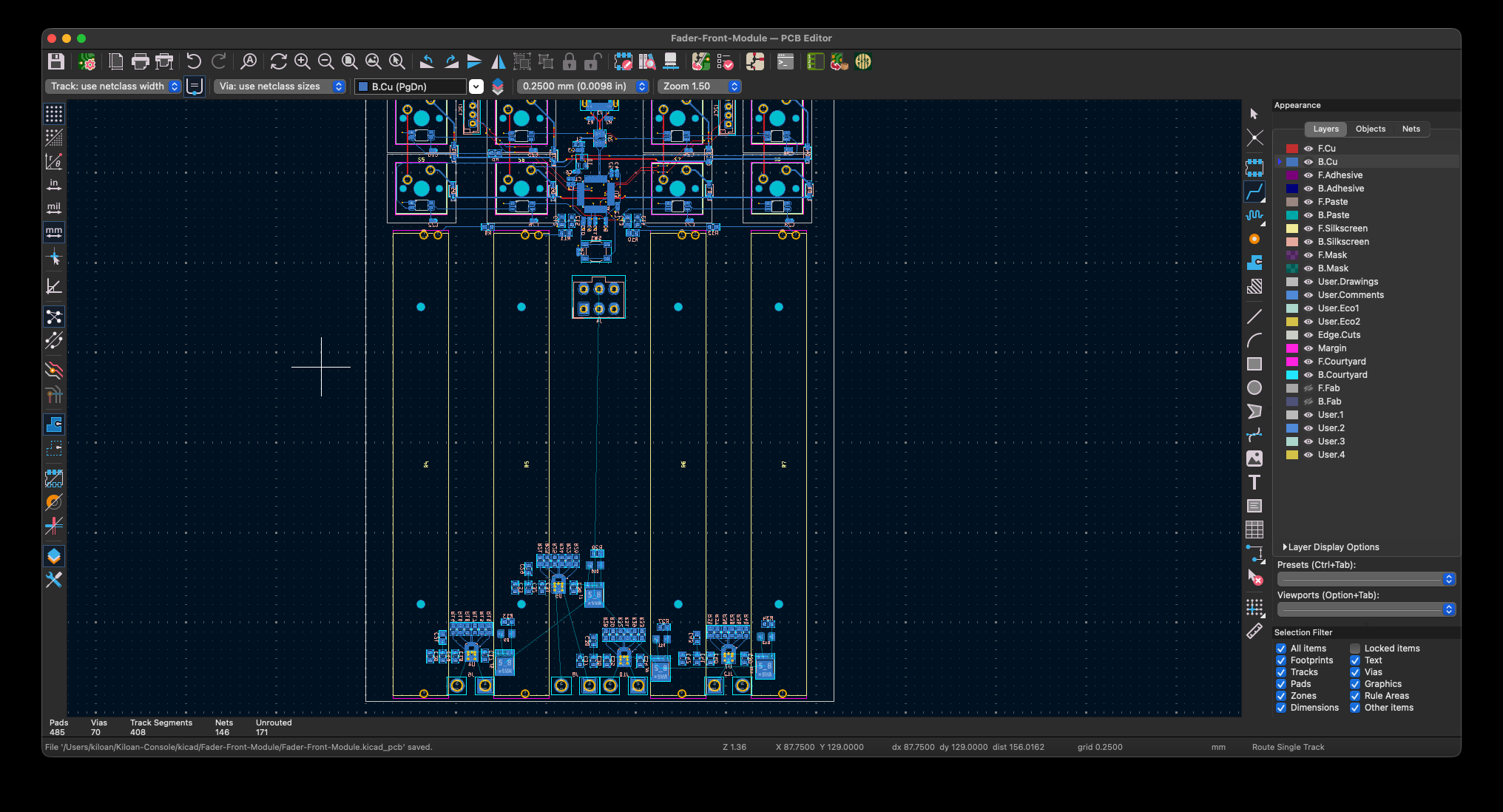

GPIO is killing me

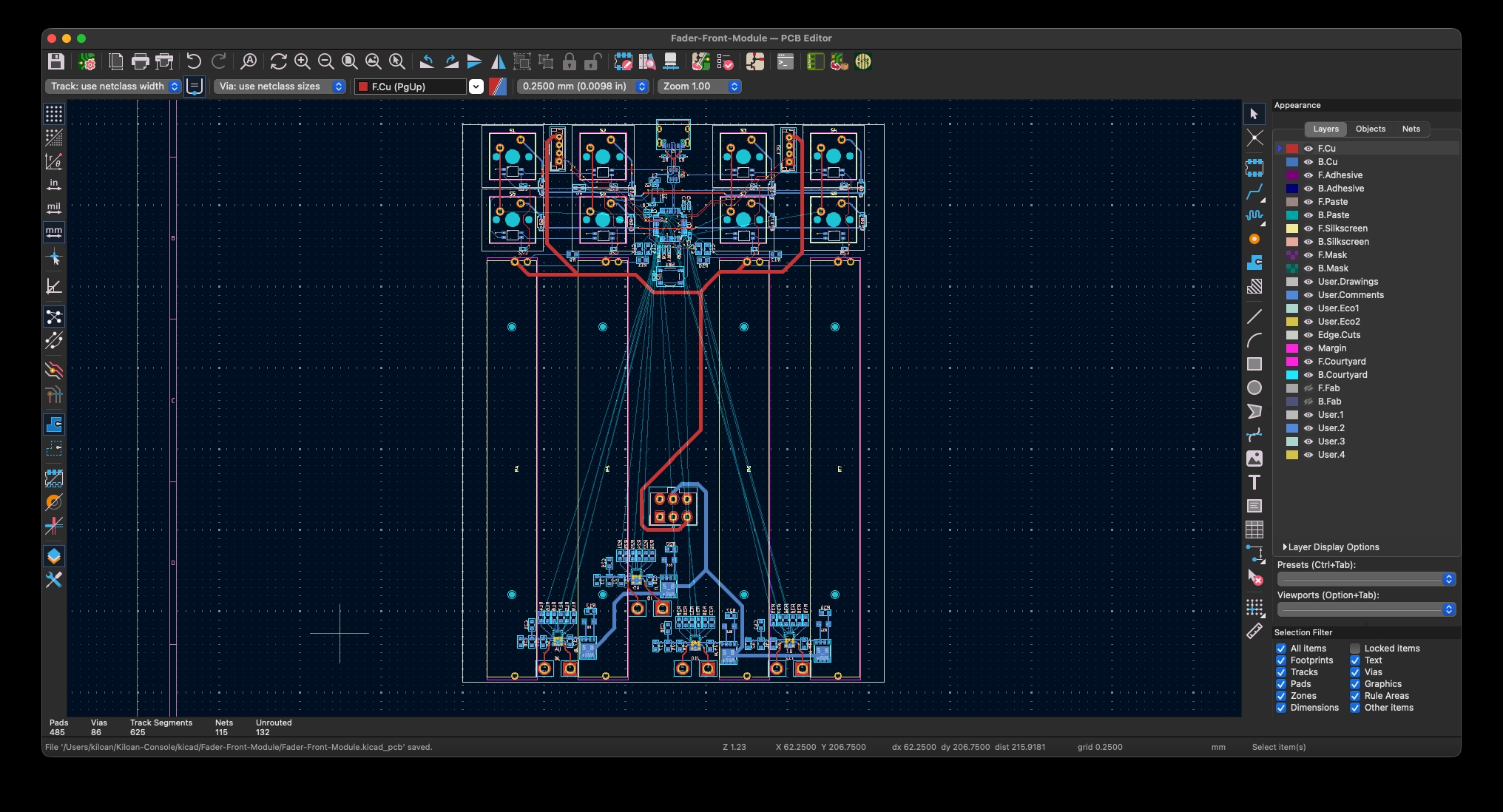

I hate routing so much. I finally finished the motor driver control pins, the LED data pin, and the switch matrix. Only the faders remain, but it's going to be very tight. My plan for today is to finally finish the PCBs and the modules.

![]() Kian

added to the journal ago

Kian

added to the journal ago

Finally some CAD

So, I just quickly converted the first PCB into a useful module! We're making progress, it won't be long before I can assemble this project in real life, I'm so excited!

.png)

.png)

![]() Kian

added to the journal ago

Kian

added to the journal ago

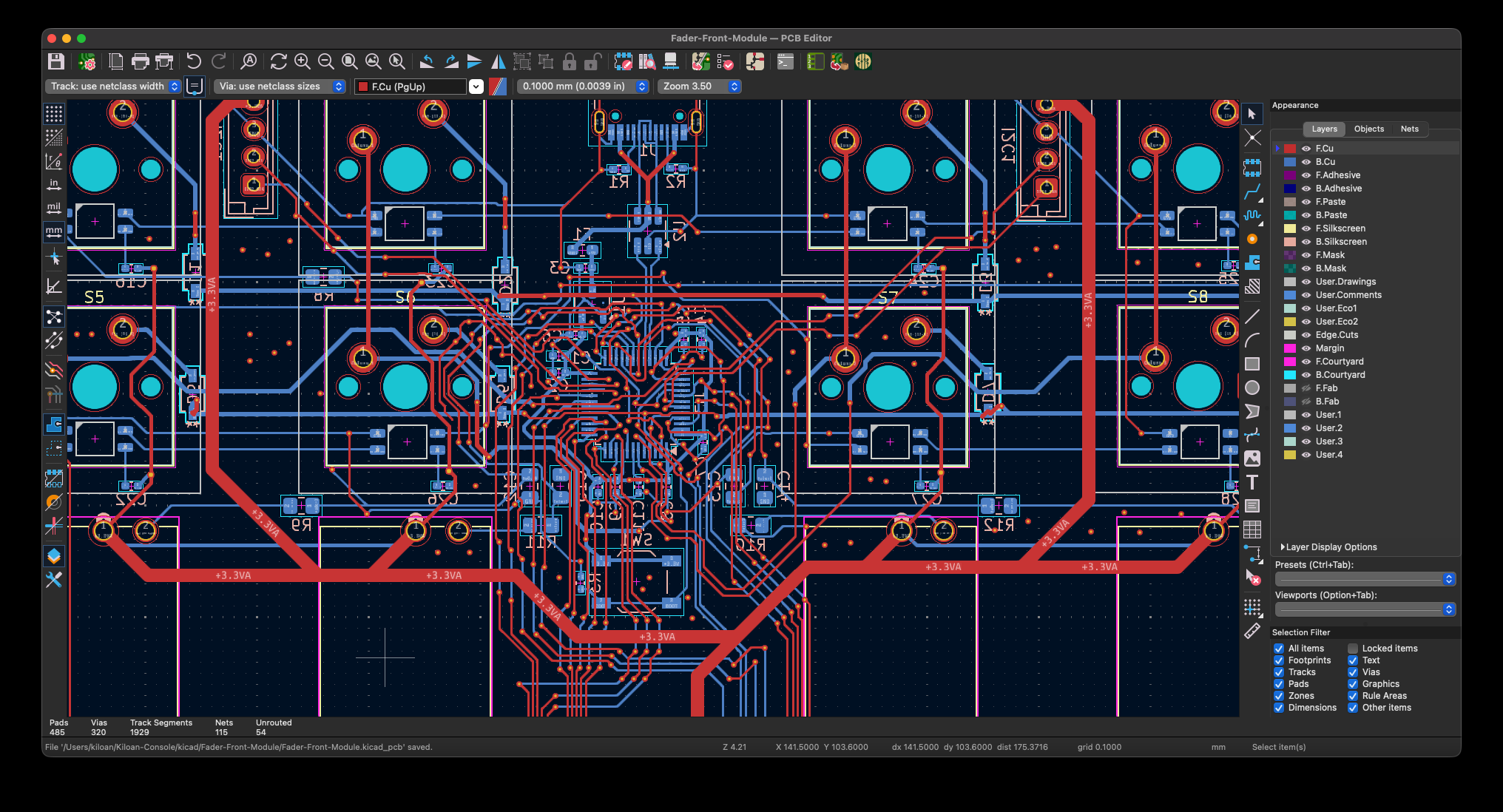

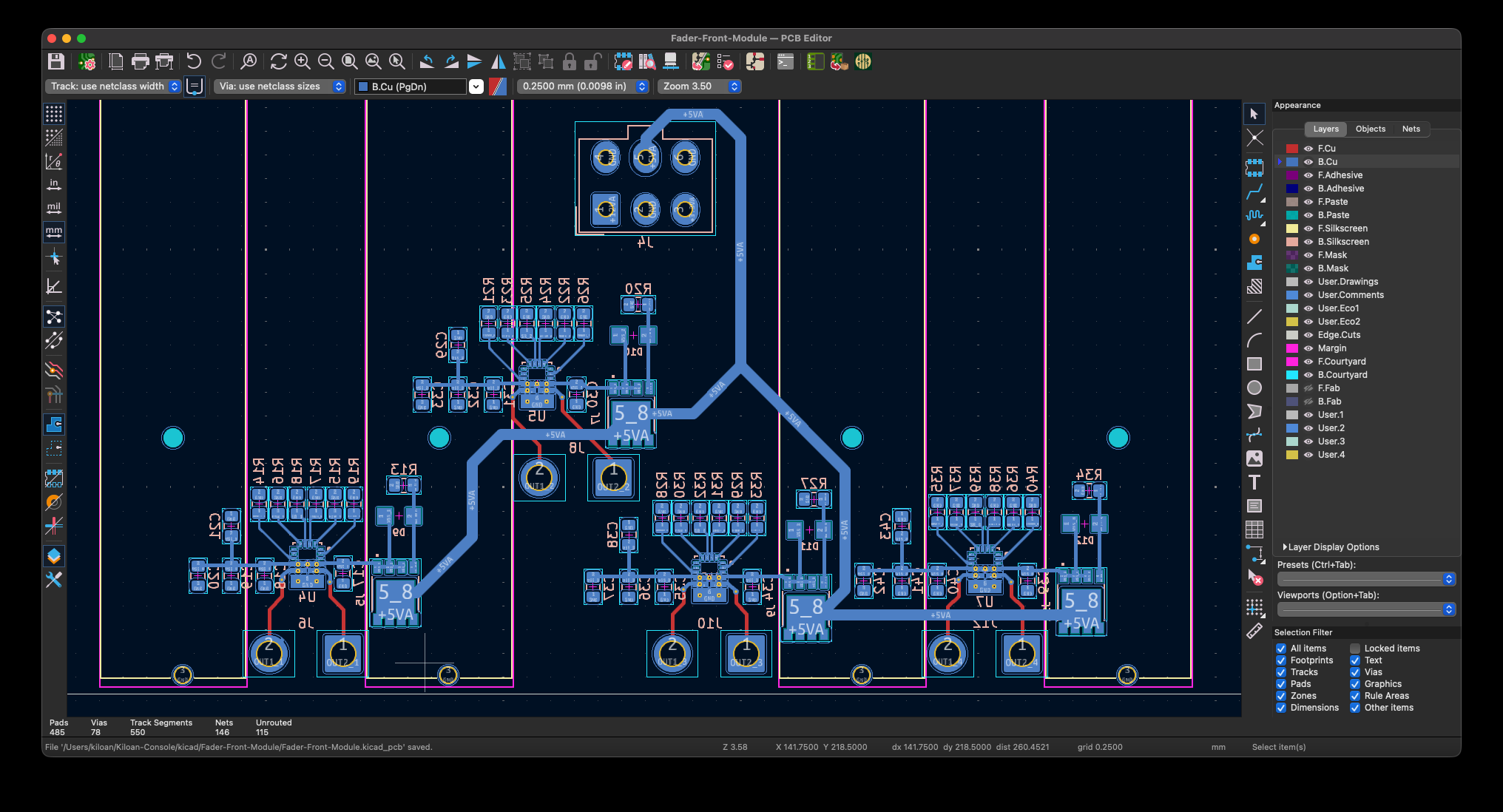

My most intense PCB Design yet...

Edit: I just realized that today's title could also be for a YouTube video haha.

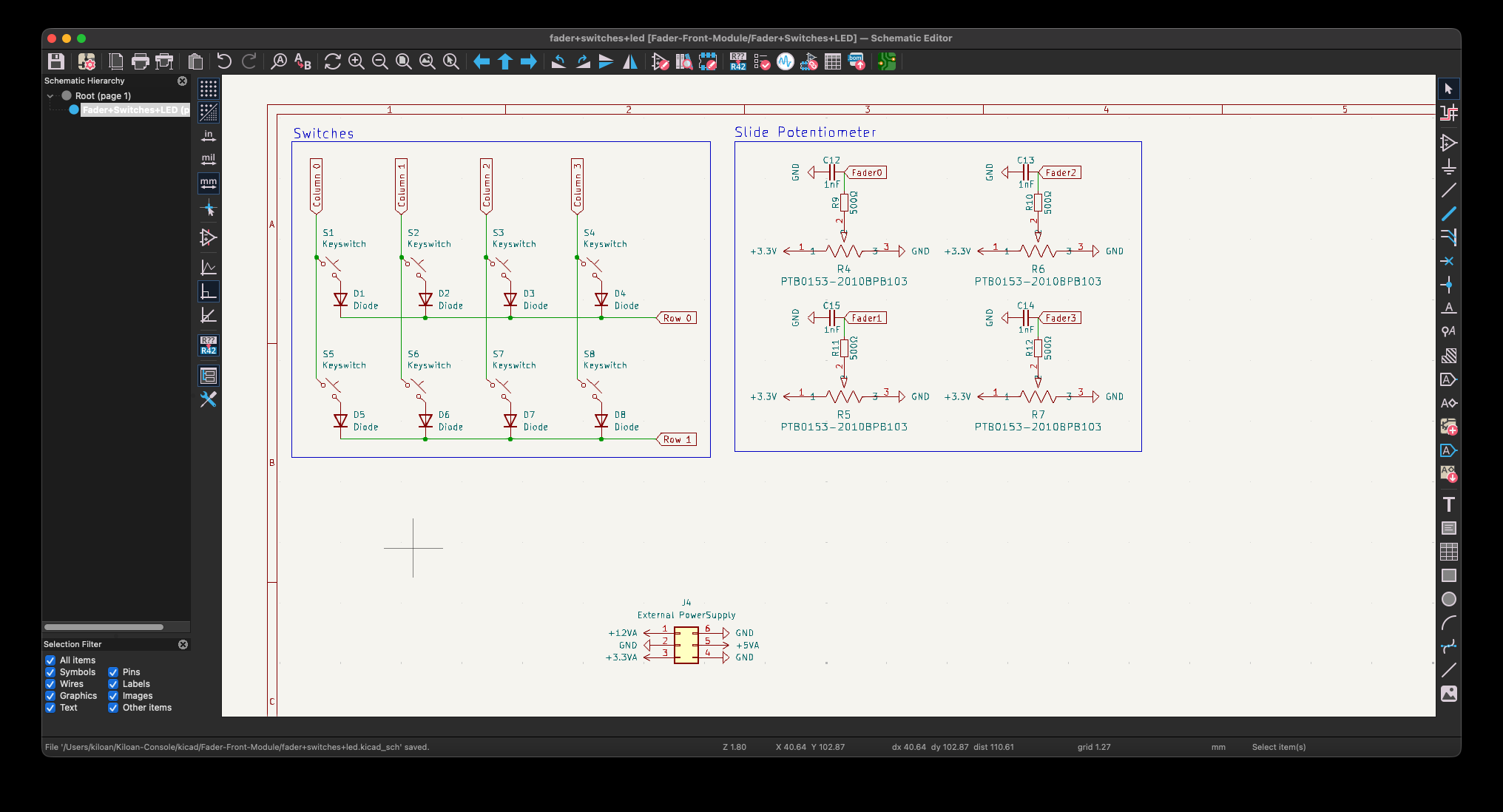

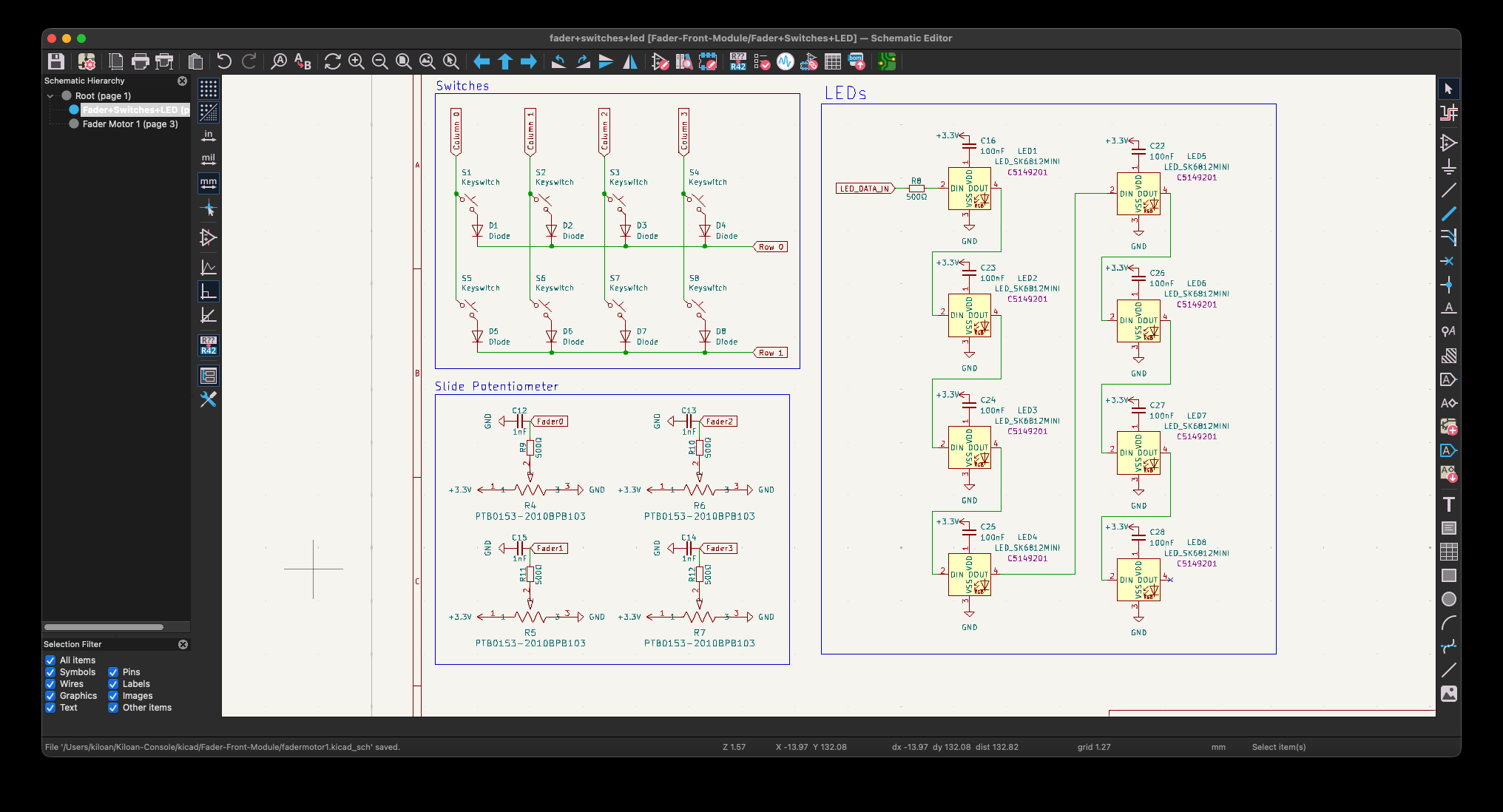

The middle PCB should have motorized faders. However, since these are very expensive, I'll build them myself. But first, let's look at the schematics. I've started with 8 switches (two for each fader) and 4 slide potentiometers.

Then, as on the other PCB, there are 8 integrated circuit LEDs to indicate the status of the respective switches. Additionally, there is a header for powering the components, so that the 3.3V line from the USB port is used only for the STM32 chip, and everything else is powered by an external power supply.

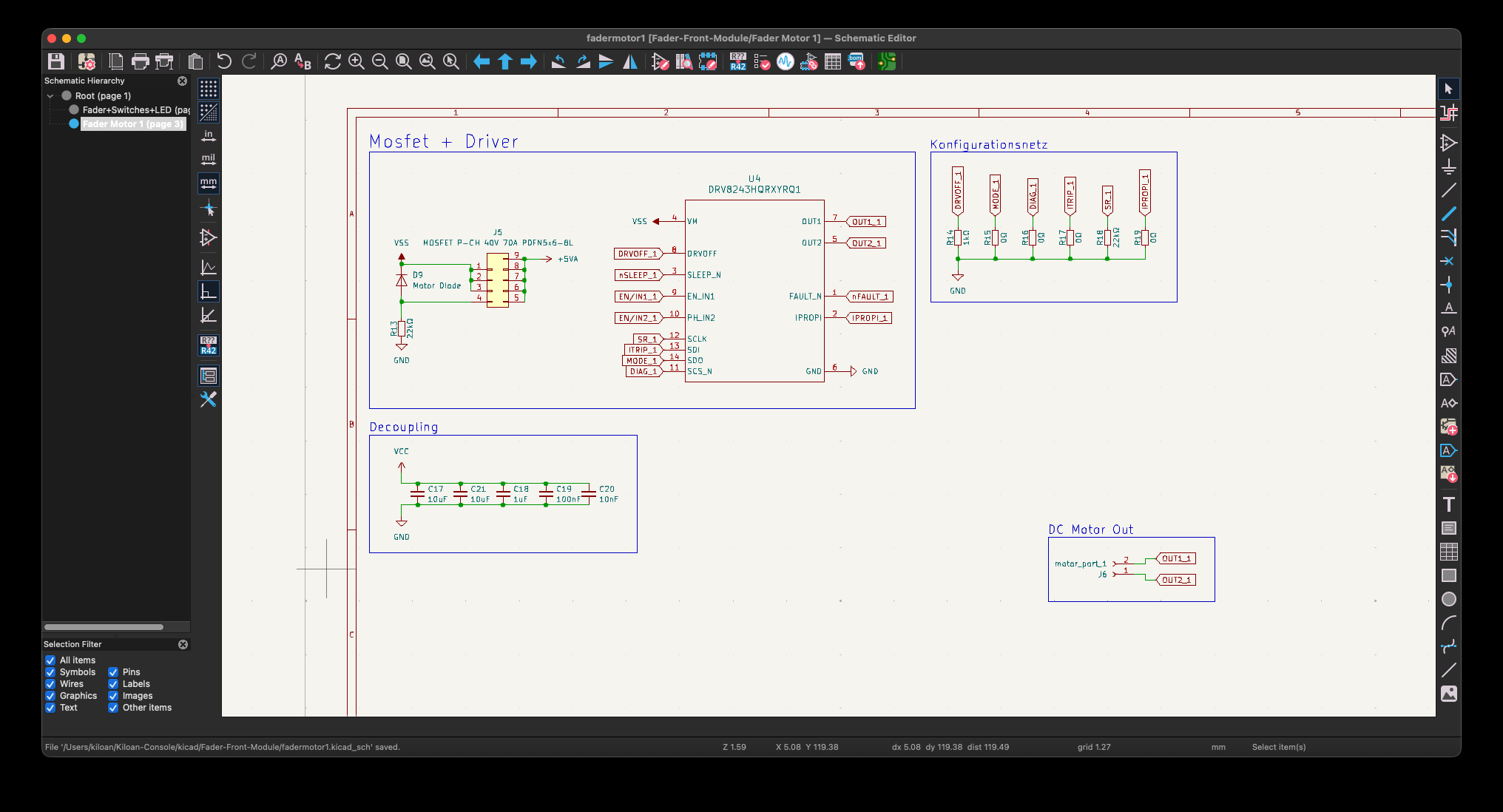

Then I built the controller for the DC motors. That was a combination of reading the driver IC's datasheet and using chatgpt, and it took by far the longest. I wanted to have finished the PCBs a long time ago, but that really held me up.

.png)

I copied the driver four times and roughly distributed the components on the PCB, then positioned them in their final positions. Then I routed the motor drivers and used the external power supply for motor current as well as for switches, faders, and LEDs. The pins for controlling the individual components will come later.

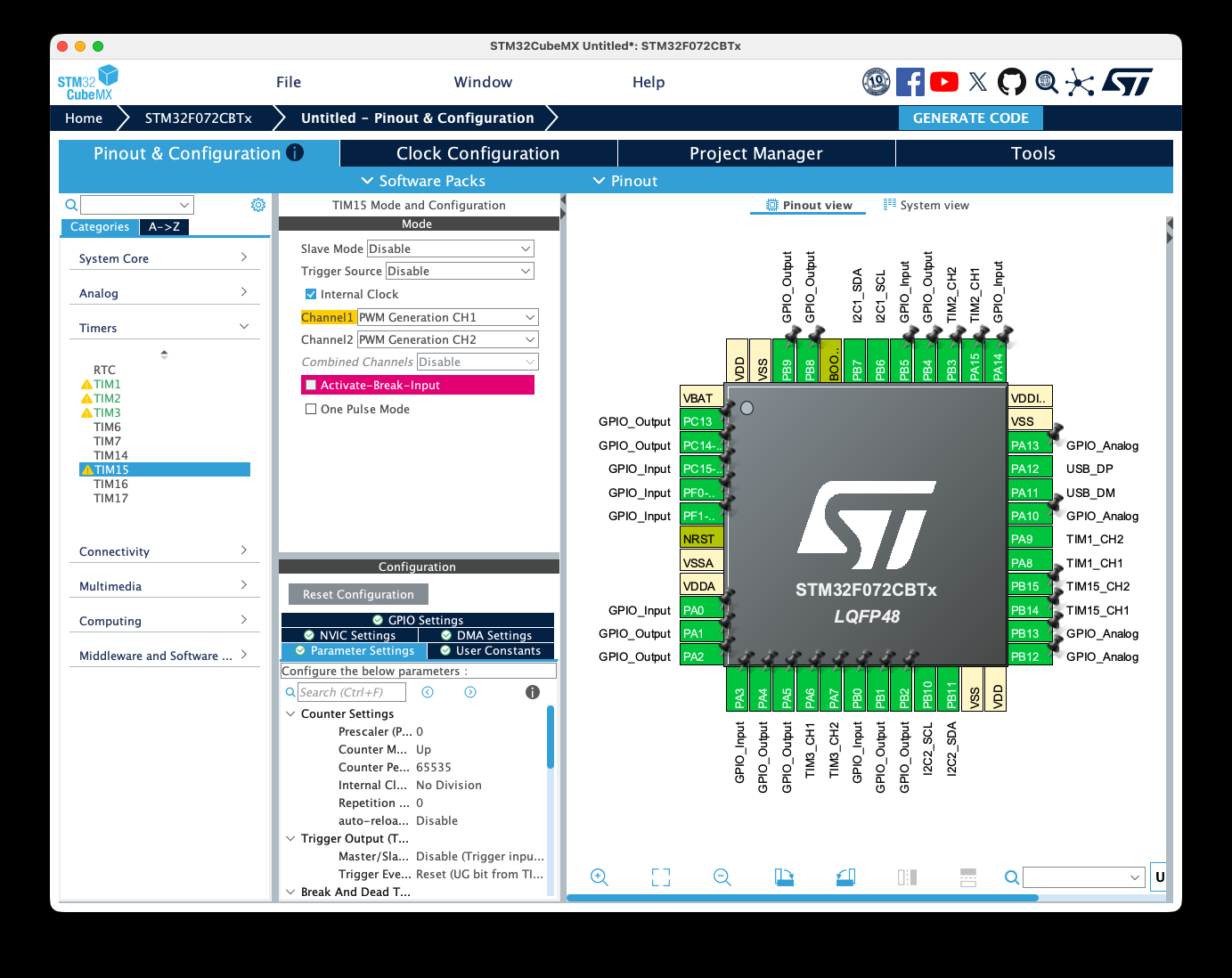

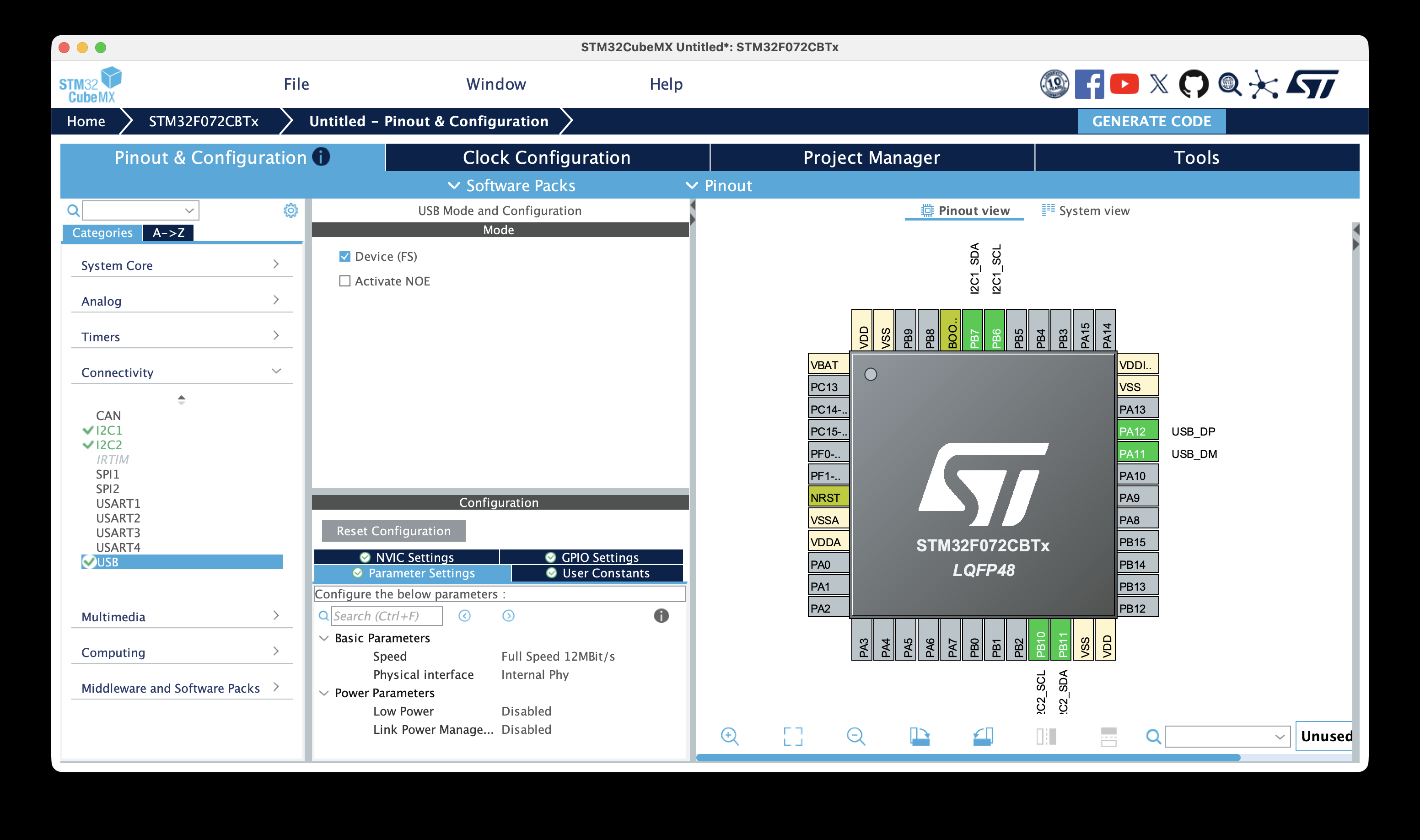

Then the GPIO pins had to be set, which again felt like it took forever, but done is done. Together with the STM32CubeMX software, the pins could be defined so that the PWM output for the motors also worked correctly.

Here are all the pins with their modes:

Now all that's left is to route all the data lines, which is what I'll be working on today... I hope it won't take me all day again and that I'll finish quickly.

And before I forget, on our first PCB the LEDs drew a bit too much current for the LDO, so I also ran the LEDs through an external power supply there, which will be present in the chassis anyway. On this board it's only 3.3V and ground.

![]() Kian

added to the journal ago

Kian

added to the journal ago

First PCB Finished

So without much writing today, although my post yesterday was very long. I've finished the PCB for the module on the far left!

Edit: Now that I look at it more closely, I think this is my most beautiful PCB so far!

It includes six switches, each with an RGB LED underneath to indicate the user's current position and what's activated. Then I neatly routed everything and created ground fills. And so, the first PCB is finished! Unfortunately, it took me a while to get to grips with the SK6812MINI-E LEDs, as this was my first time using this type of LED and integrated circuit LEDs in general. Here are a few more photos.

![]() Kian

added to the journal ago

Kian

added to the journal ago

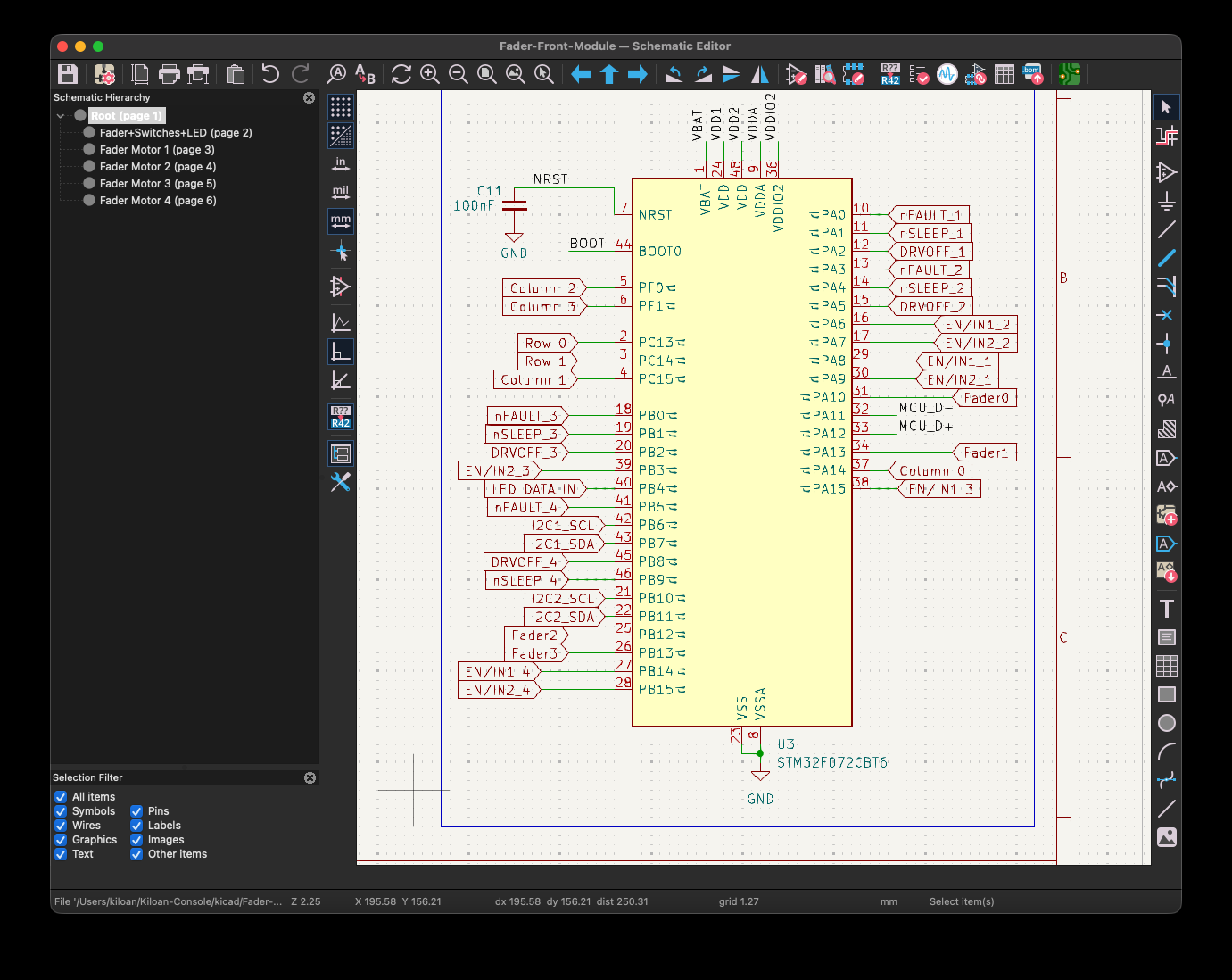

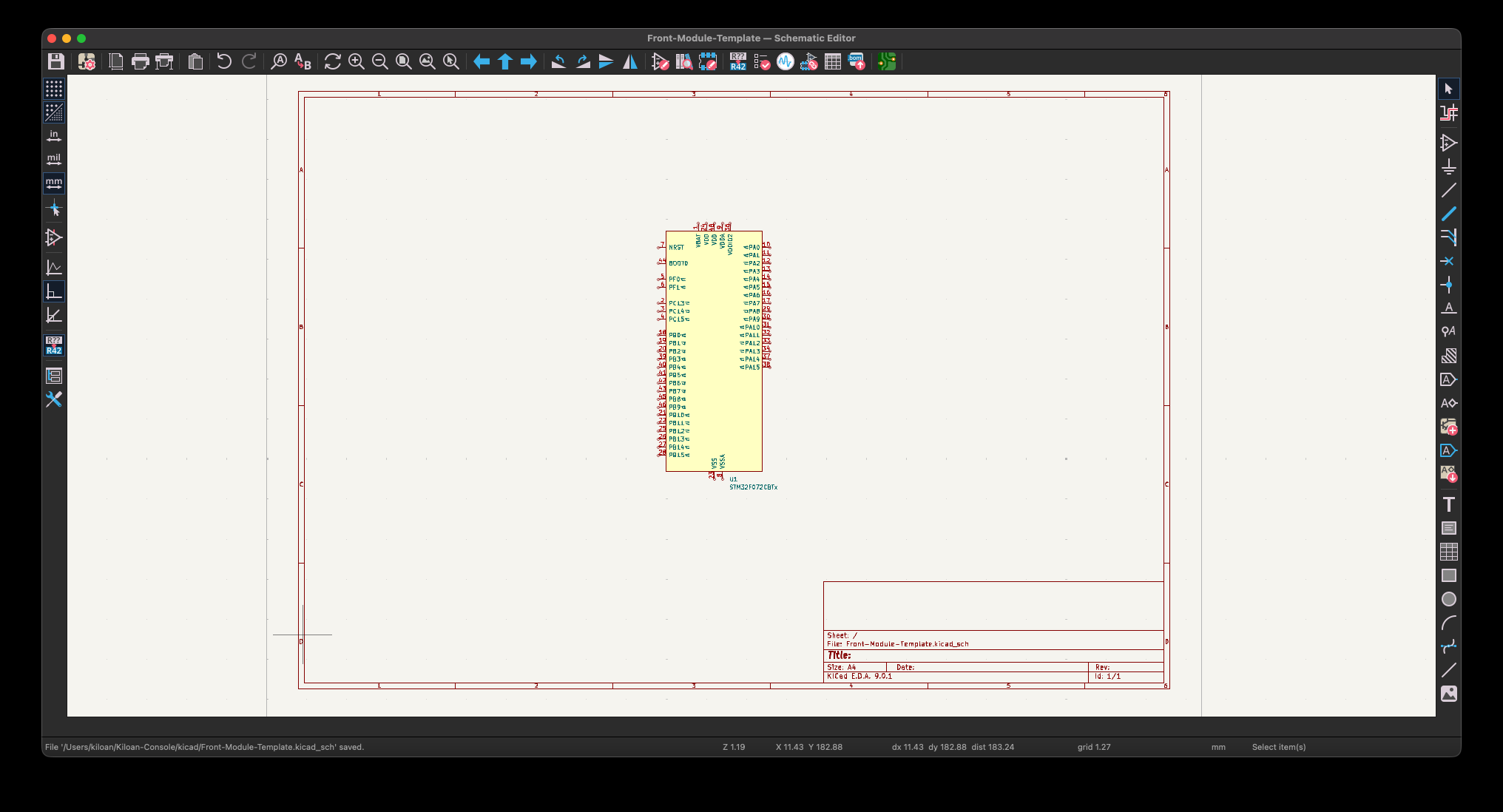

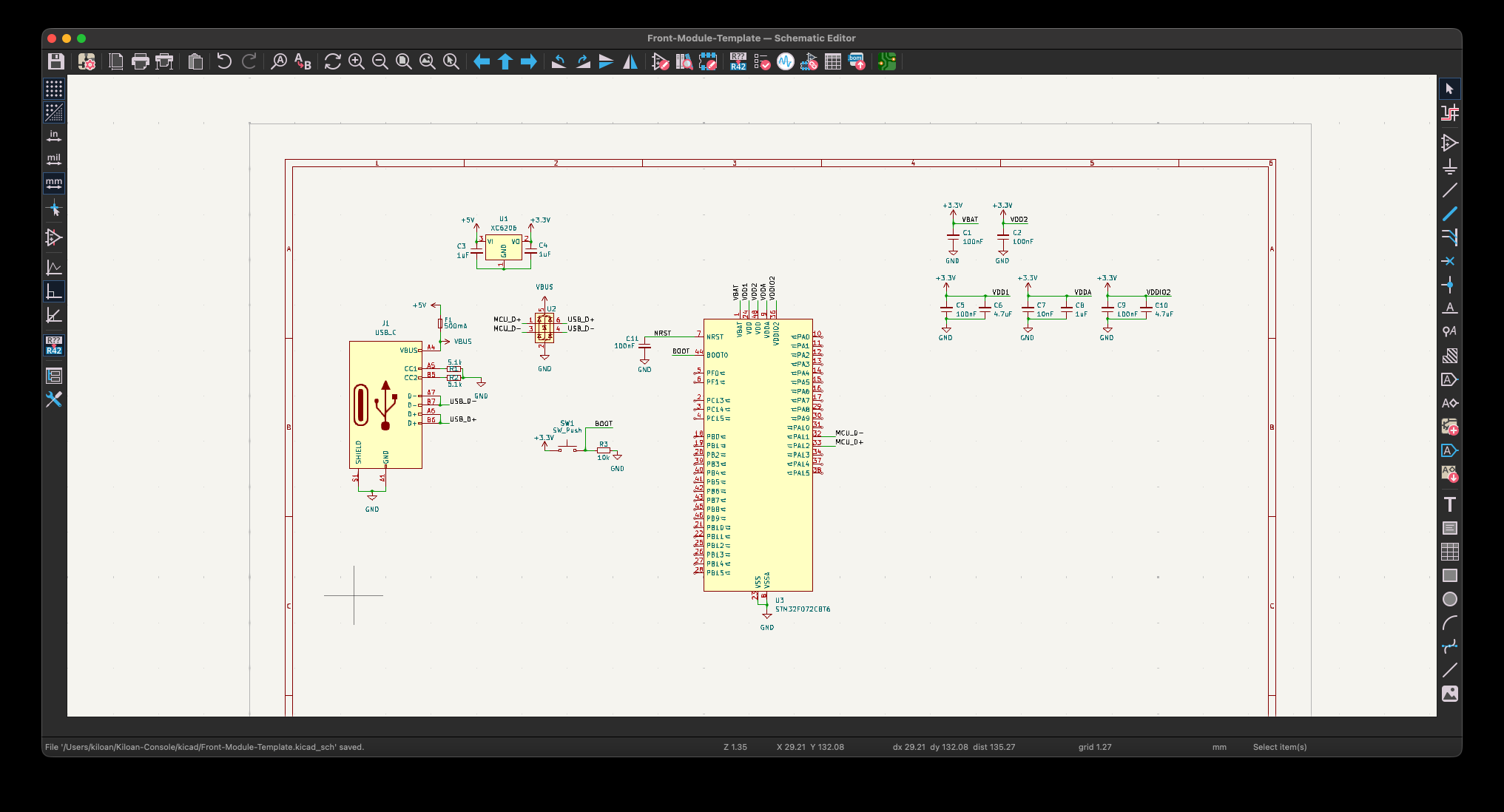

PCB Modul Template + first PCB (halfway finished)

It's Thursday evening and way too late. I actually wanted to work late into the night tomorrow on this project so I could finally finish it. I have so many other project ideas, and when I think about it, a month until the end seems like a terribly short time. Anyway let's get to the important part. I won't go into too much detail because this whole thing has taken far too long. But first a picture of the pcb progress:

I started with the symbol for the STM-32 chip.

Then I added the USB-C port and routed it through the ESD protection to the processor's integrated USB interface, since we already identified the correct pins yesterday using the STM32CubeMX software. I also stepped down the voltage from 5V to 3.3V, added decoupling capacitors as described in the datasheet, and added the bootloader button.

The schematic file has been made a bit nicer and more organized, and the two I2C interfaces have been made available via two connectors in order to later connect the boards/oled screens together.

I somehow took a lot of screenshots today, and here you can see that I forgot the ground connection in the voltage step-down circuit. If you look at previous images, you'll see this. Luckily, I noticed it in time.

Then I roughly routed the components so that you can easily add components like switches, faders, and other things to build the individual PCBs for the front panel in the chassis.

The whole thing is set up as a template project in the KiCad folder in the repository. I then created the first board from this project for the narrow module on the far left. It has led switches (transparent switches with an rgb led under it) and an OLED screen on top, which is separate and connected via one of the I2C headers. It's not fully routed yet, but since the difficult initial setup with the processor is done, this module and the others should now be quick to implement. More tomorrow.

![]() Kian

added to the journal ago

Kian

added to the journal ago

more research

It's much too late right now and I can't work on the PCBs anymore, but I used the last hour and a half chatting with chatgpt on a train journey to figure out what all makes sense for the "control system" in the chassis. So, how the PCBs are connected, how to use that effectively in the code, and so on. Hopefully, I'll have more details tomorrow.

really nice picture because I need it to save this entry :-)

![]() Kian

added to the journal ago

Kian

added to the journal ago

Research

I did some more research and discovered that working with an ESP32 isn't nearly as difficult as I thought. There's this great tool called STM32CubeMX where you simply specify which protocols you need, and it shows you exactly which pins are available for them. I love it—finally, no more tedious datasheets to read! If I'd known this earlier, I would have started using the STM32 chip much sooner.

If I manage to do it tomorrow evening, I'll continue with the basic layout of the individual PCBs, the basic components, and the individual slide potentiometers and switches.

![]() Kian

added to the journal ago

Kian

added to the journal ago

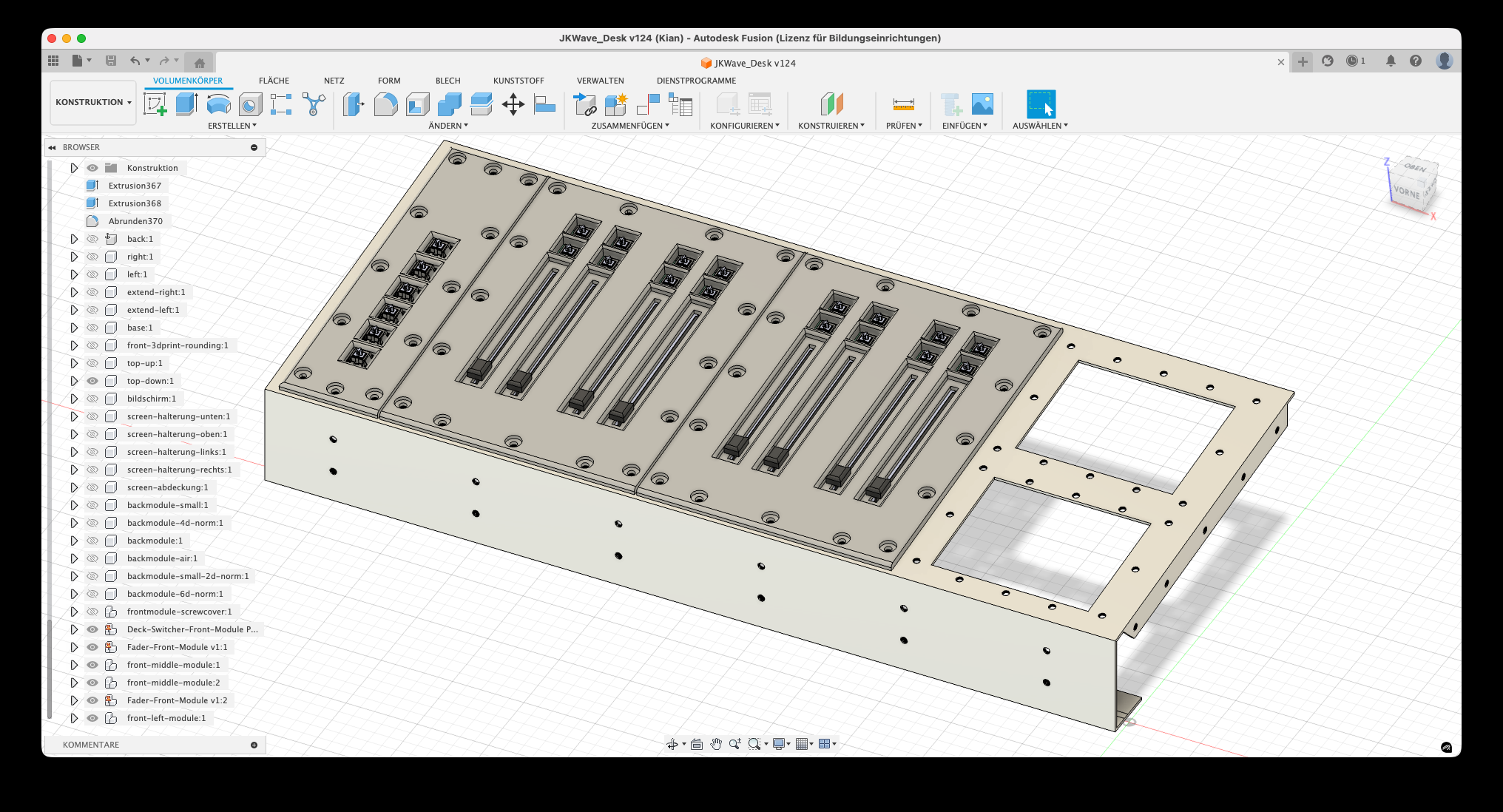

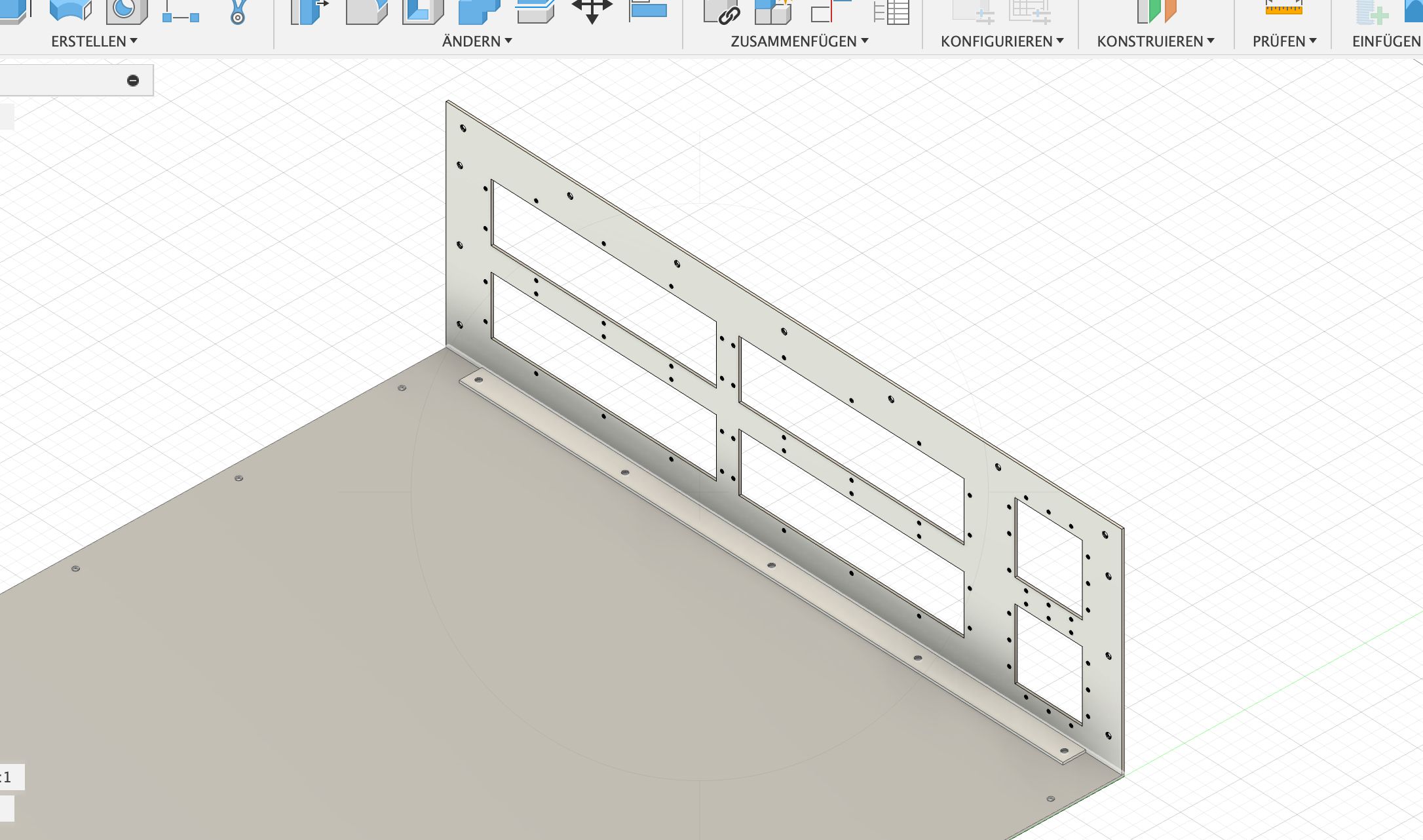

Back/front modules + pcb things

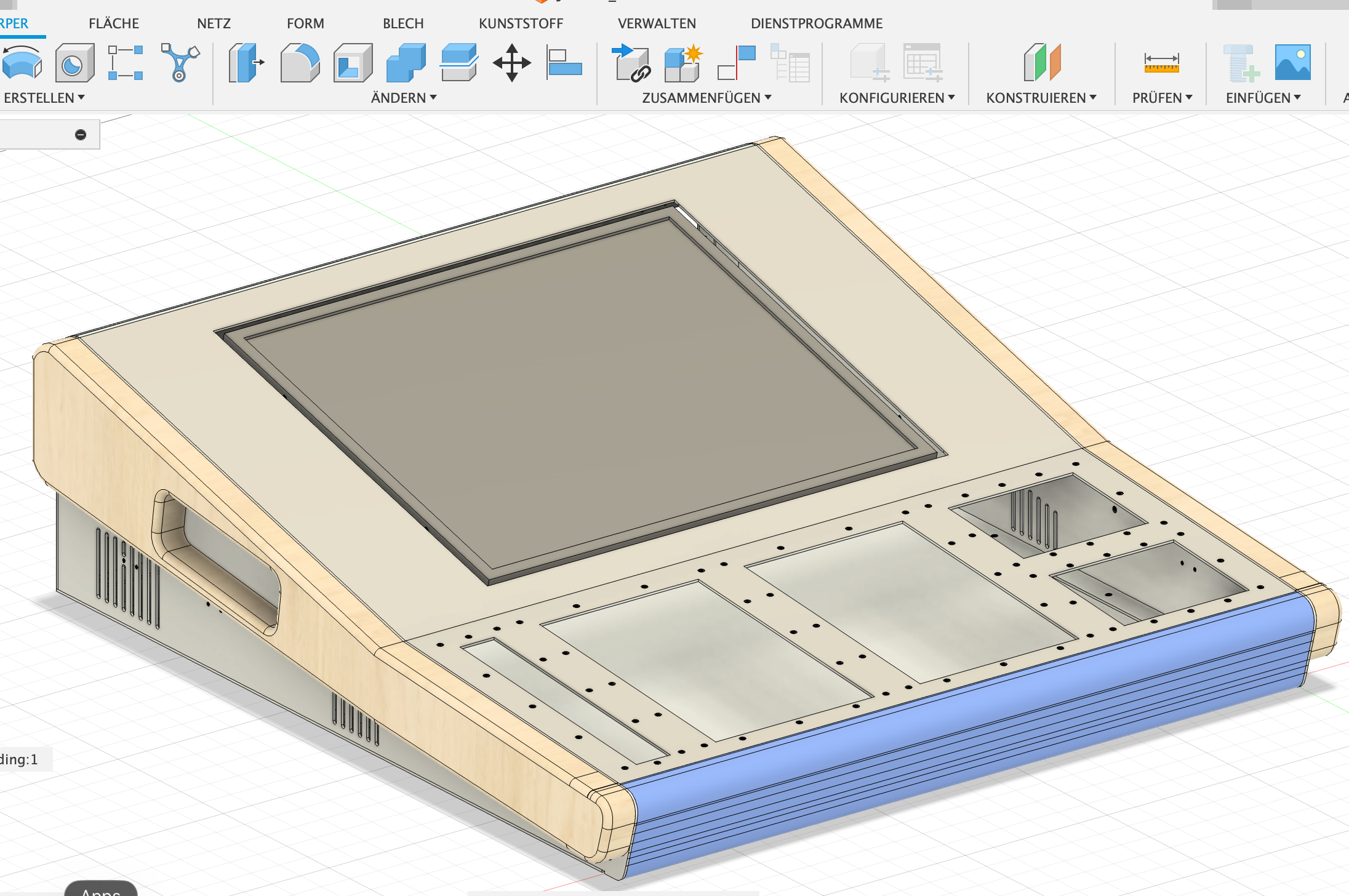

It's been two days since my last post. Since we have exams every week, I'm a bit behind schedule. Yesterday I didn't get anything done and everything took longer than expected, but the modules for the back are finished. I've started the modules for the front, but before I can finish those, I need to design the PCBs. Here's an update photo, I'll go into more detail about each item in a moment.

I started with the modules for the back panel. Since these are to be 3D printed, they are simply plates with module slots for D-type sockets. Of course, these can also be extended like proper plug-in modules so that they protrude to the back and can be slid in, but this isn't necessary for me yet. Perhaps in the future, who knows? You need everything eventually.

I continued working on the modules for the front panel. These are still just plates, but once finished, they will become proper modules that extend further down and fit perfectly into the cutouts in the sheet metal, especially because of the PCBs with the components for operation. I don't yet know how the individual components will communicate with each other, but more on that later. First some photos:

And once the desired modules are installed, 3D printed covers can be inserted where the screws are to make the screws invisible. When modifying the modules, these can simply be pried out, and if damaged, they can be reprinted in under 2 minutes.

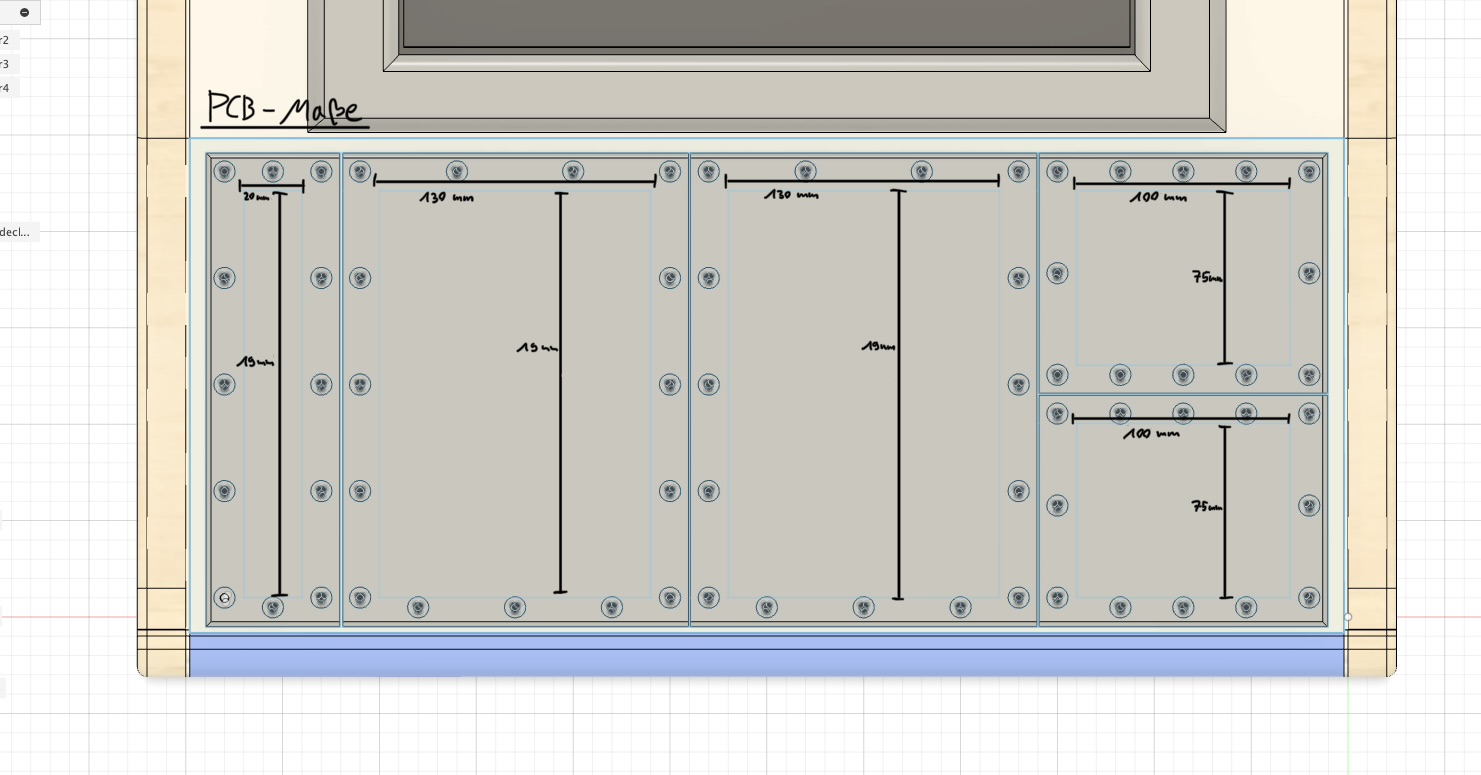

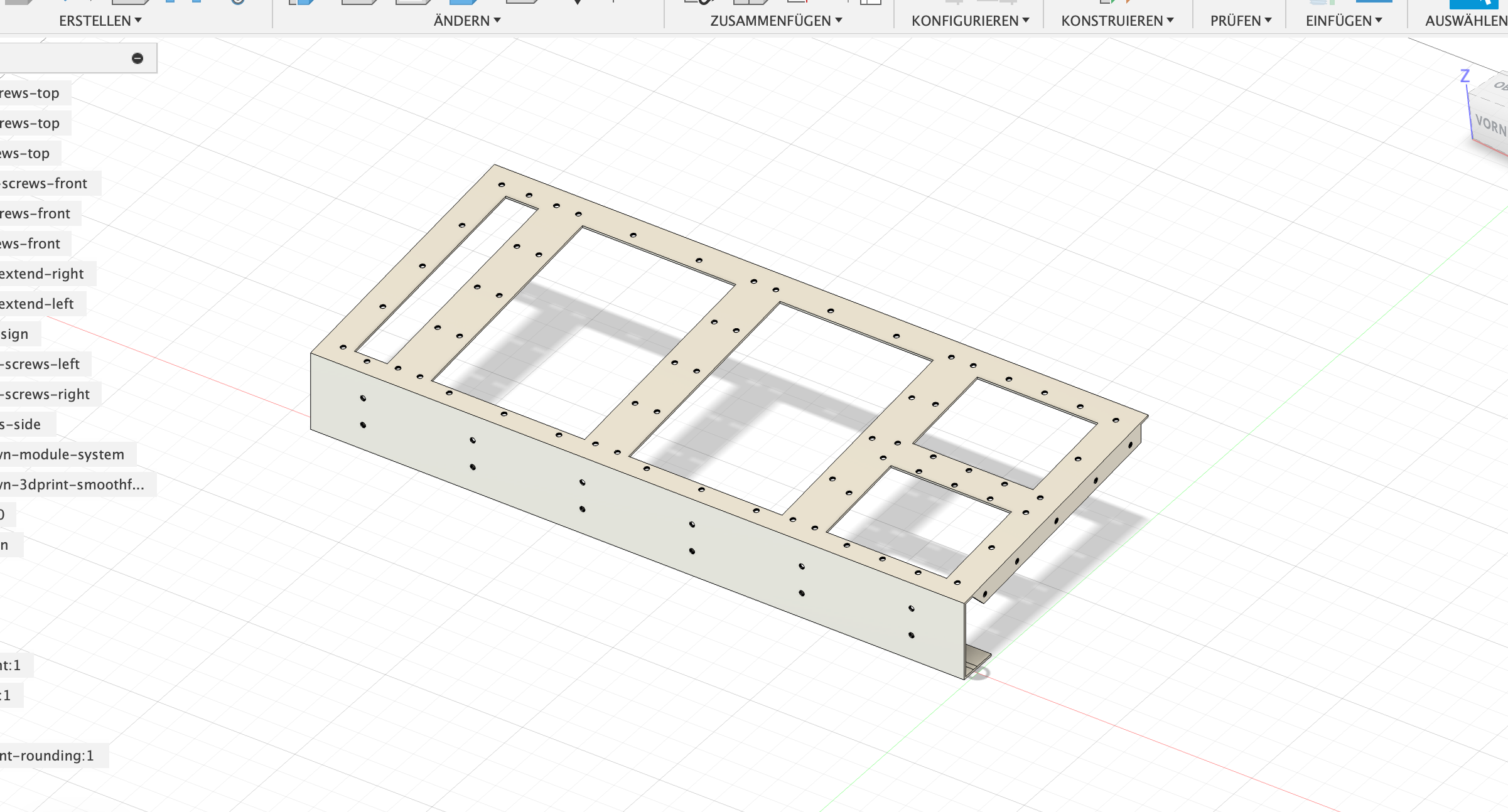

Let's move on to the PCBs and my ideas/goals for them. First, here are the maximum sizes the PCBs can have for the modular system to still work. I almost specified the exact dimensions of the metal panel cutouts, but then the modules wouldn't work at all :-/ Good thing I just noticed that.

So my idea was that the two large modules would be equipped with motorized slide potentiometers and then, like on larger mixing consoles, the left module would have knobs or switches with multi-colored LEDs underneath allowing you to control multiple channels with the slide potentiometers adjusting to the respective status. Reading this, you're probably wondering what I'm even planning to do with this. Good question, let me explain my vision.

The most important thing is that everyone can recreate this console to suit their needs, but I'm reaching the point where I need to adapt it for my purposes. I plan to combine it with my DIY digital mixing console but also use it to control DMX devices. That's why the slide potentiometers are motorized. I'm curious to see where this project leads me and hope to share my knowledge in a club at my school.

I don't think I've ever written so much before haha but it has to be done today. The smaller modules on the left will have an OLED screen, potentiometers, and simple switches. Since the LEDs don't drive up the cost of this project, these buttons will also have LEDs underneath them. Each PCB has a USB output for sending and receiving MIDI data and for programming the processor. I want to use an STM-32 processor, more precisely the STM32F072CBT6, because it's relatively inexpensive, performs well, and has integrated USB capabilities. For transmitting information, such as changing decks, I would simply use I2C. That's the plan so far, let's get started.

![]() Kian

added to the journal ago

Kian

added to the journal ago

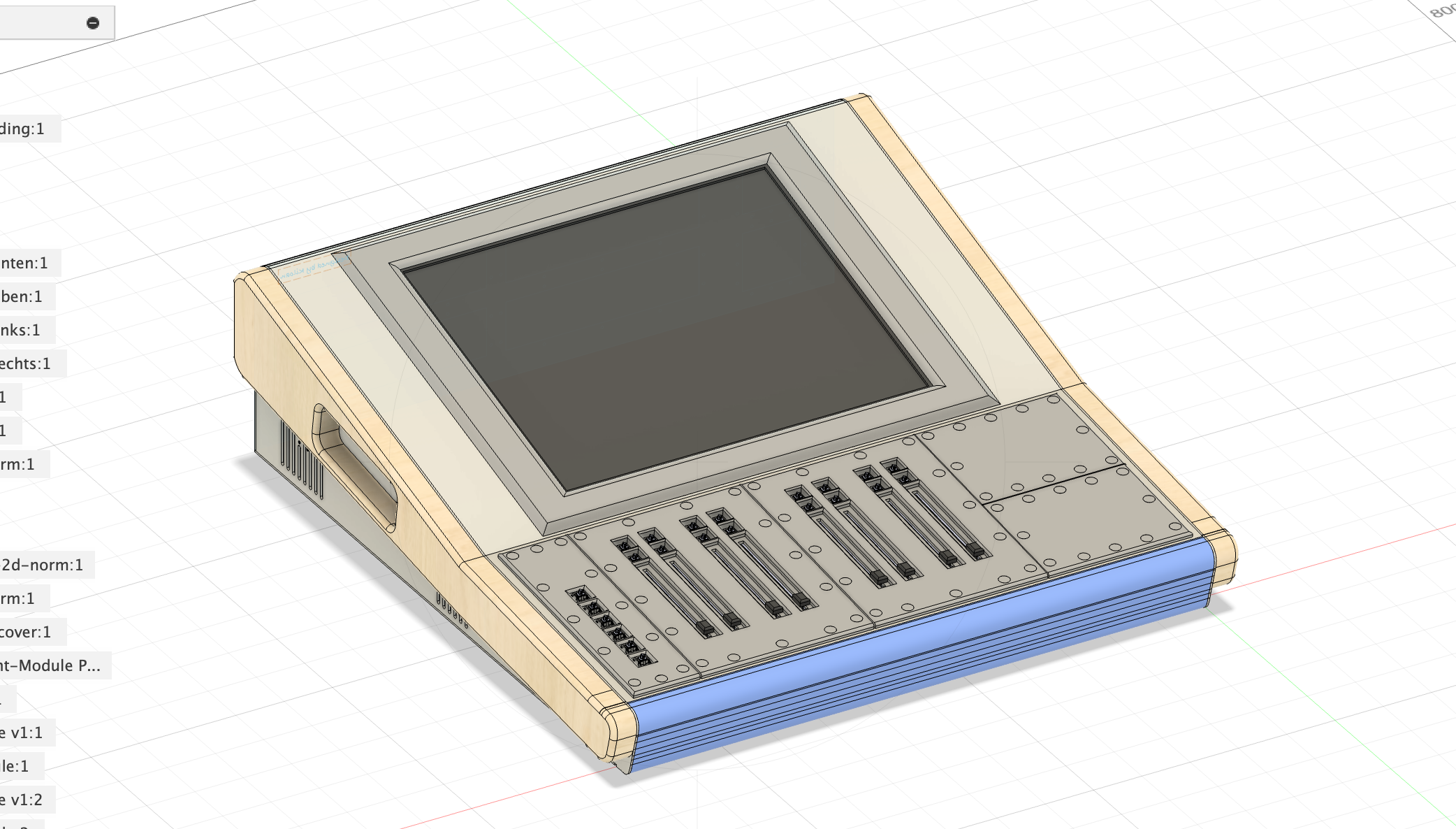

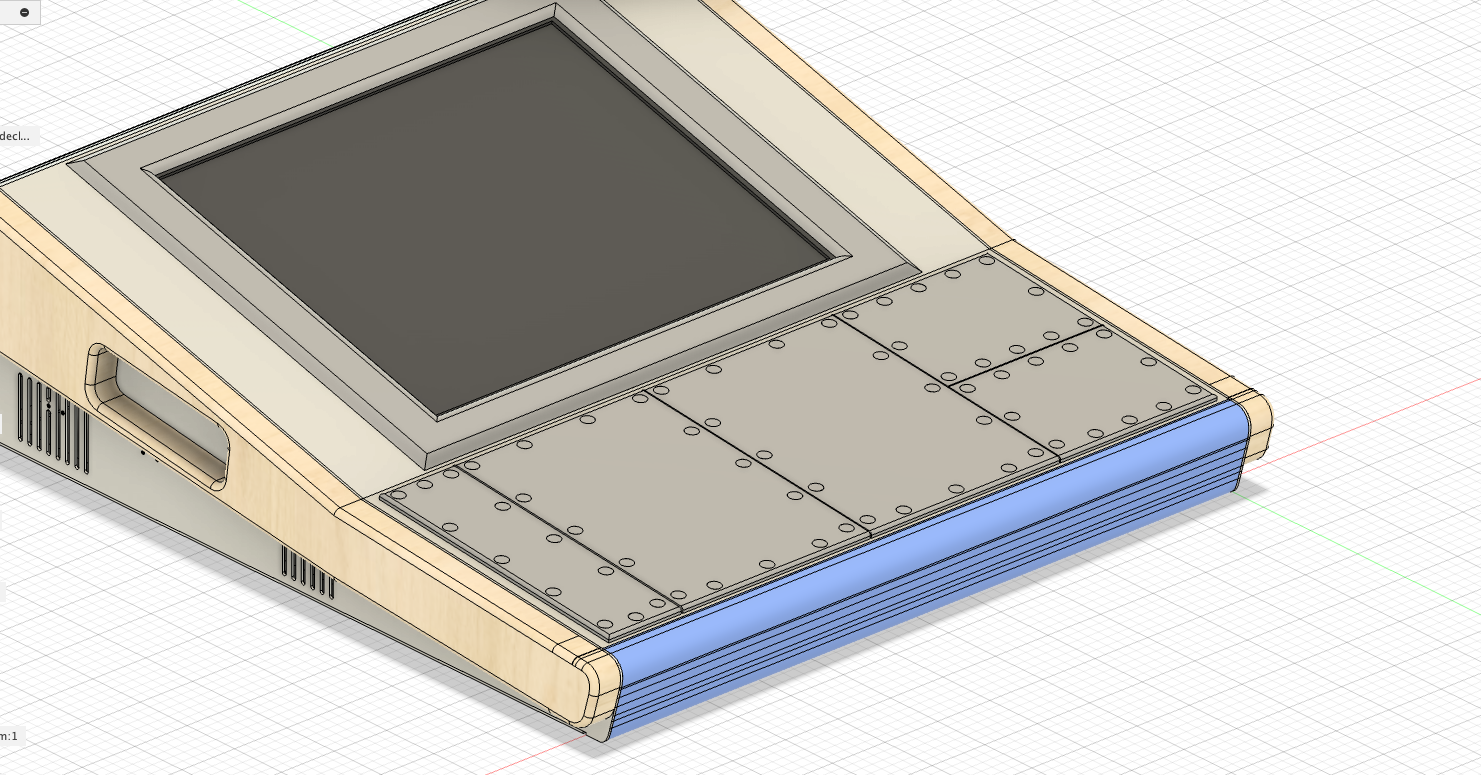

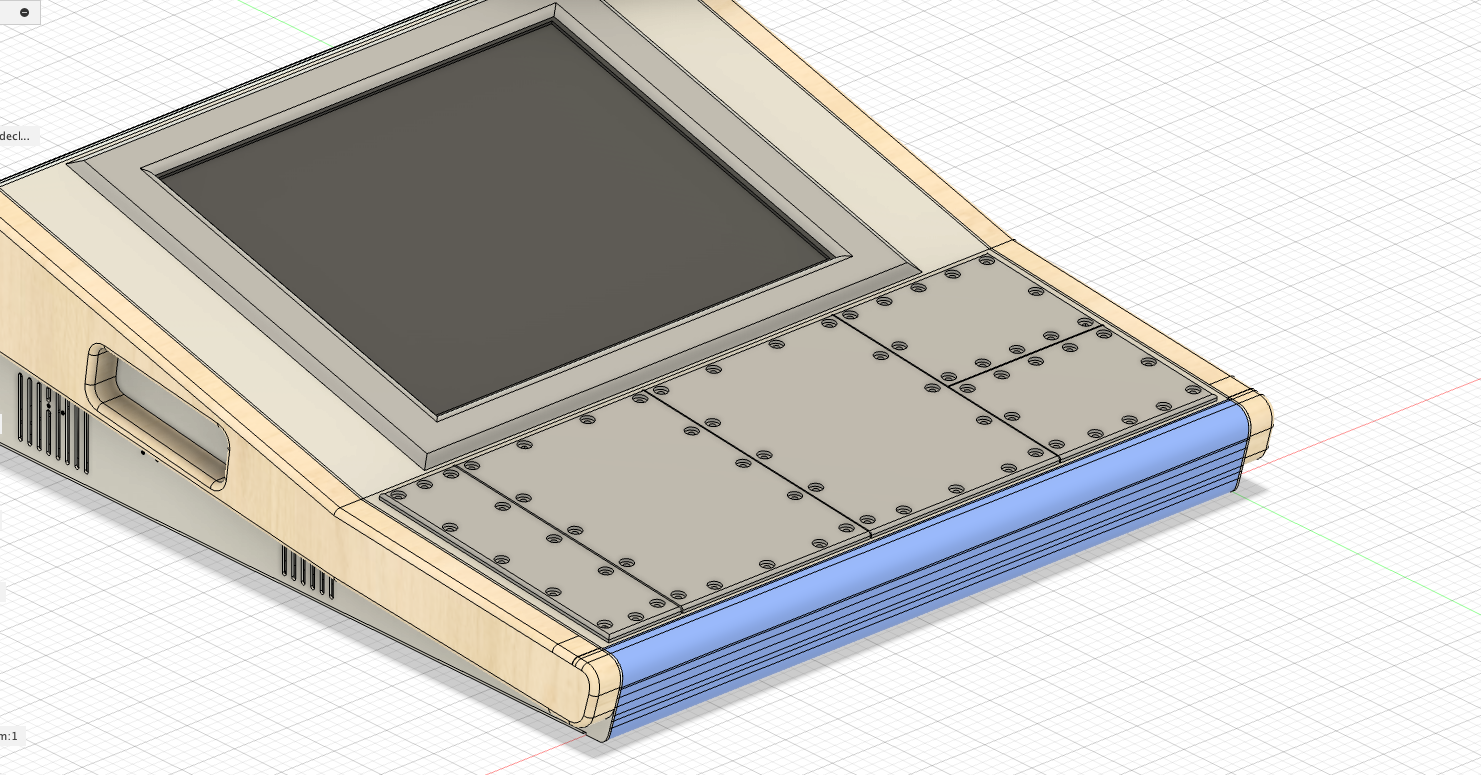

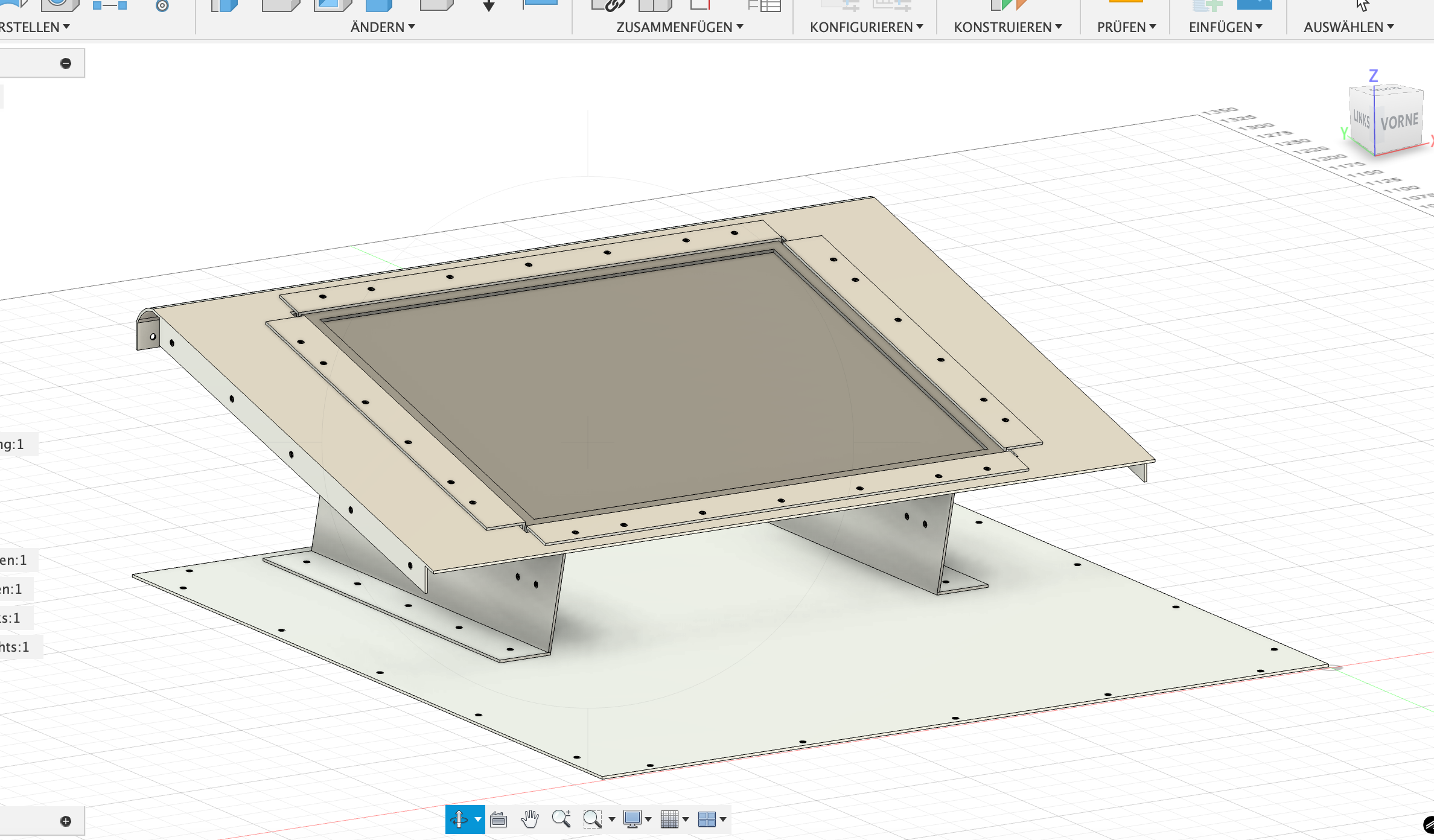

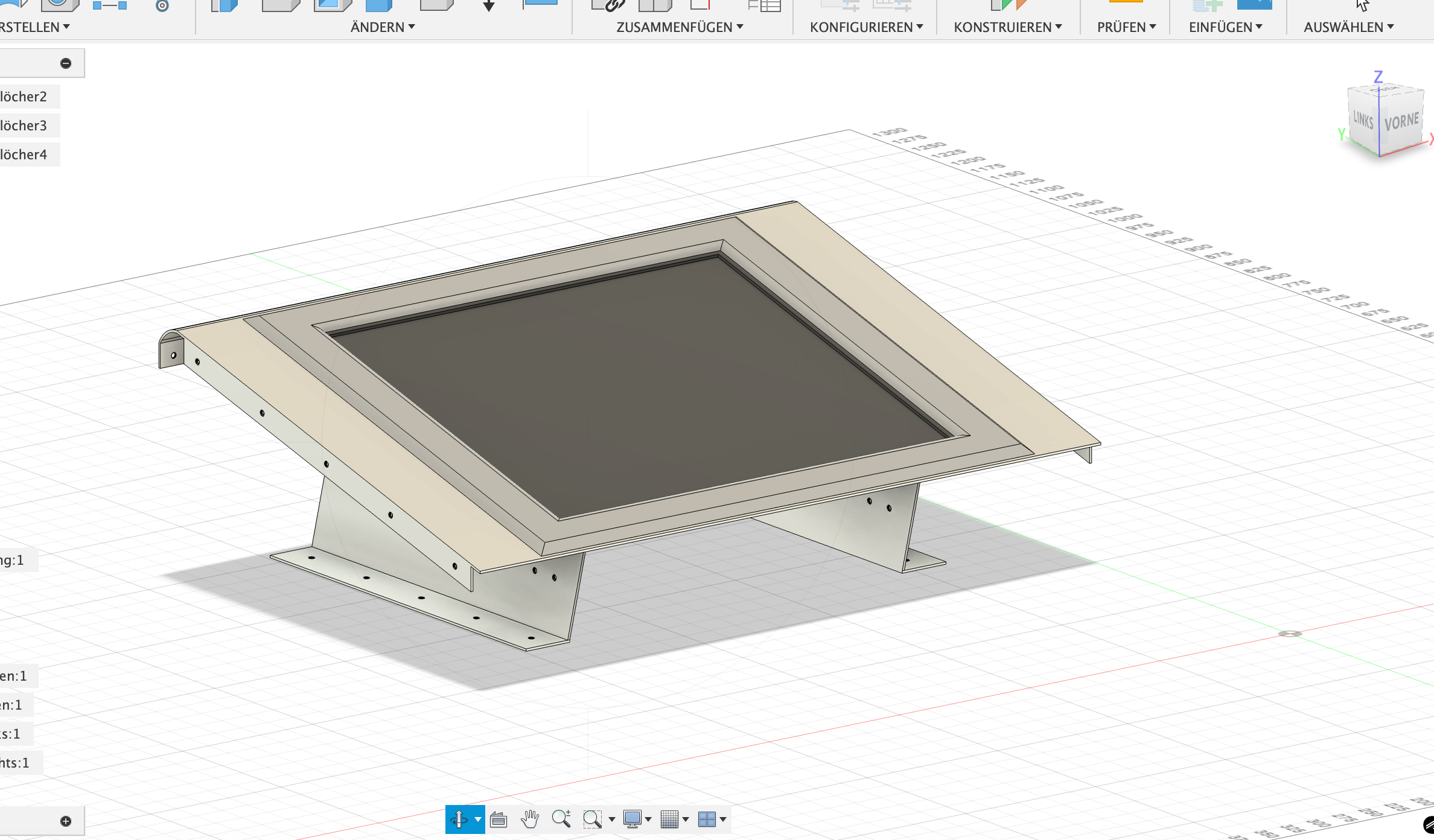

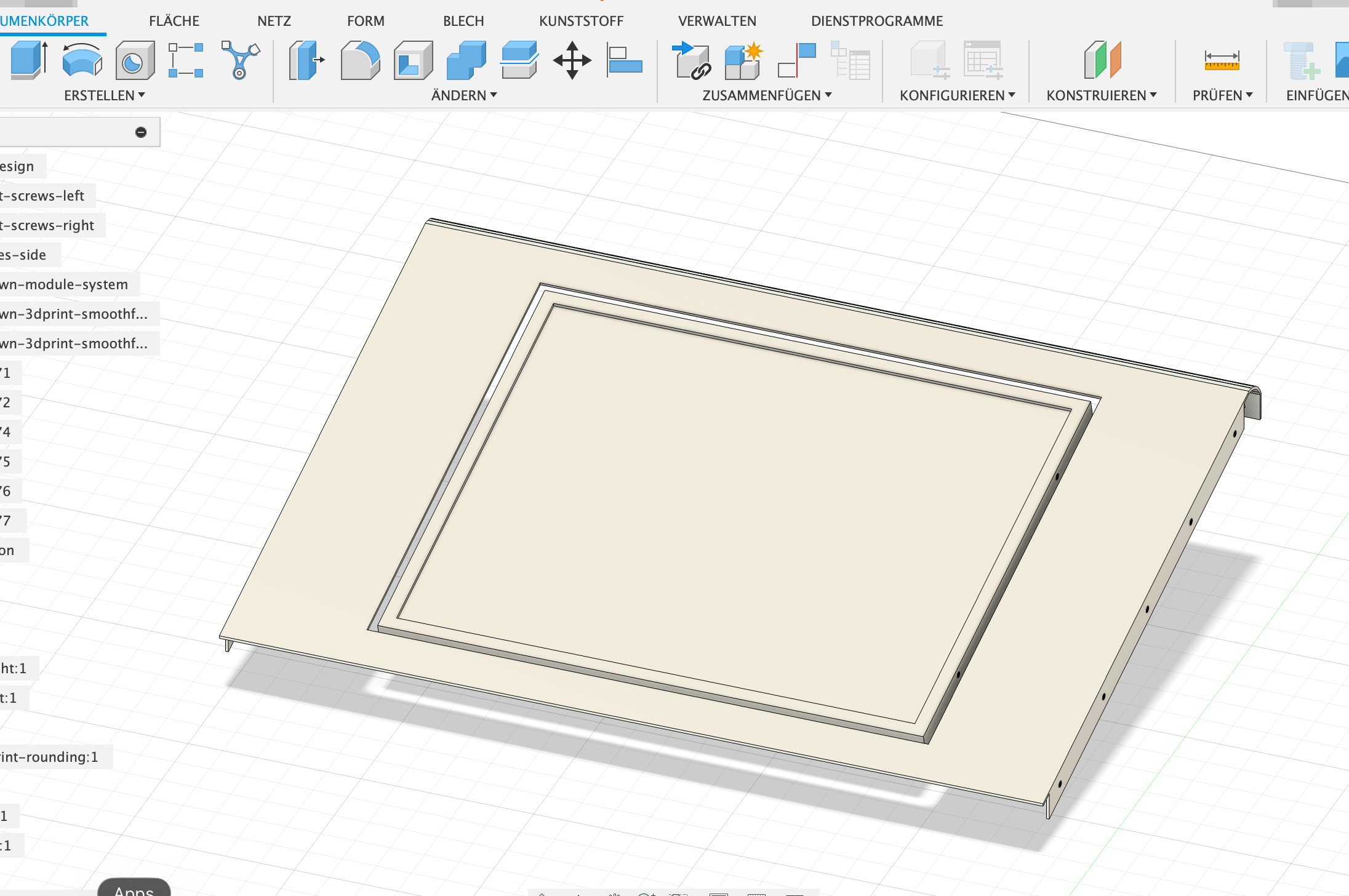

Display Mounting Solution + 3d printed aesthetics

Today I spent a lot of time working on the display and modeled the entire mounting for it in the upper part of the chassis. I'll explain how I envisioned it in a moment, first here's a picture of the current state:

So it's actually not as complicated as I thought. First we have two simple brackets at the top and bottom of the screen, on which the screen rests. On the sides the screen isn't just resting, but is secured with screws. These side brackets extend to the base plate of the chassis, so the weight is distributed further and everything is super stable. I'm waiting for the results from JLCCNC to see if it's possible to have these side brackets custom-made or if I need to modify anything. Incidentally, I've decided to use JLCCNC as the manufacturer because they are cheaper to produce and ship than other retailers.

Where the display brackets are screwed onto the top of the chassis (using M5 screws, of course), I've created a neat cover that can be 3D printed in four parts and then screwed on from below. This gives the whole thing a high-quality finish, especially around the screen.

![]() Kian

added to the journal ago

Kian

added to the journal ago

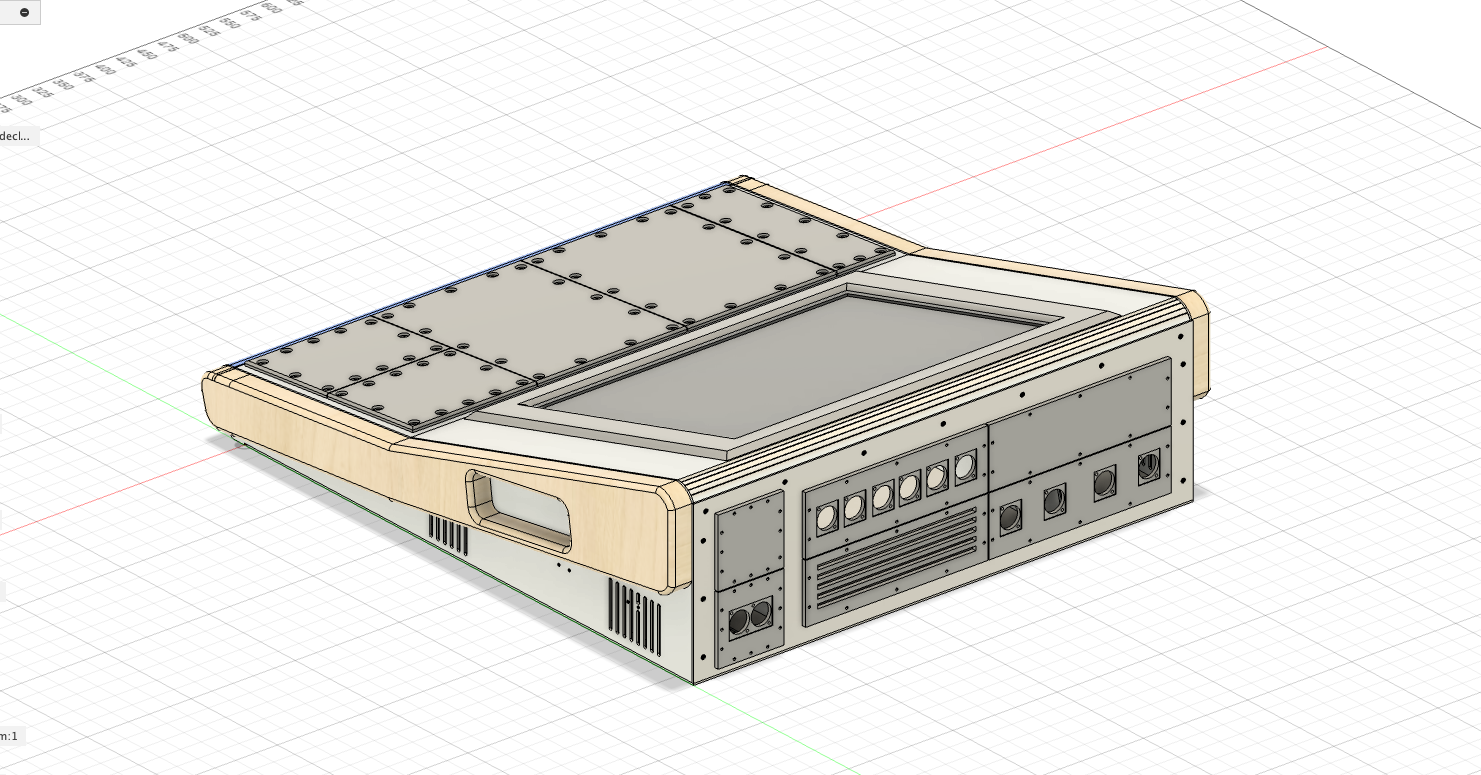

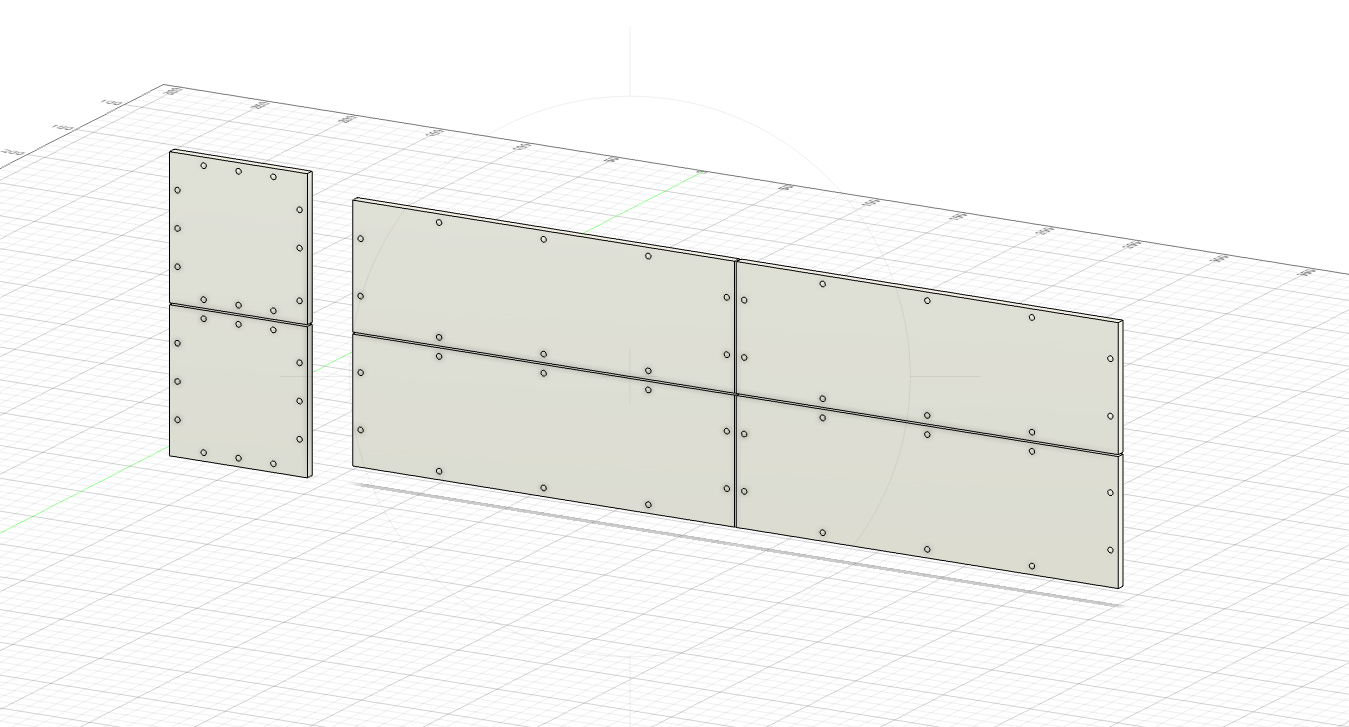

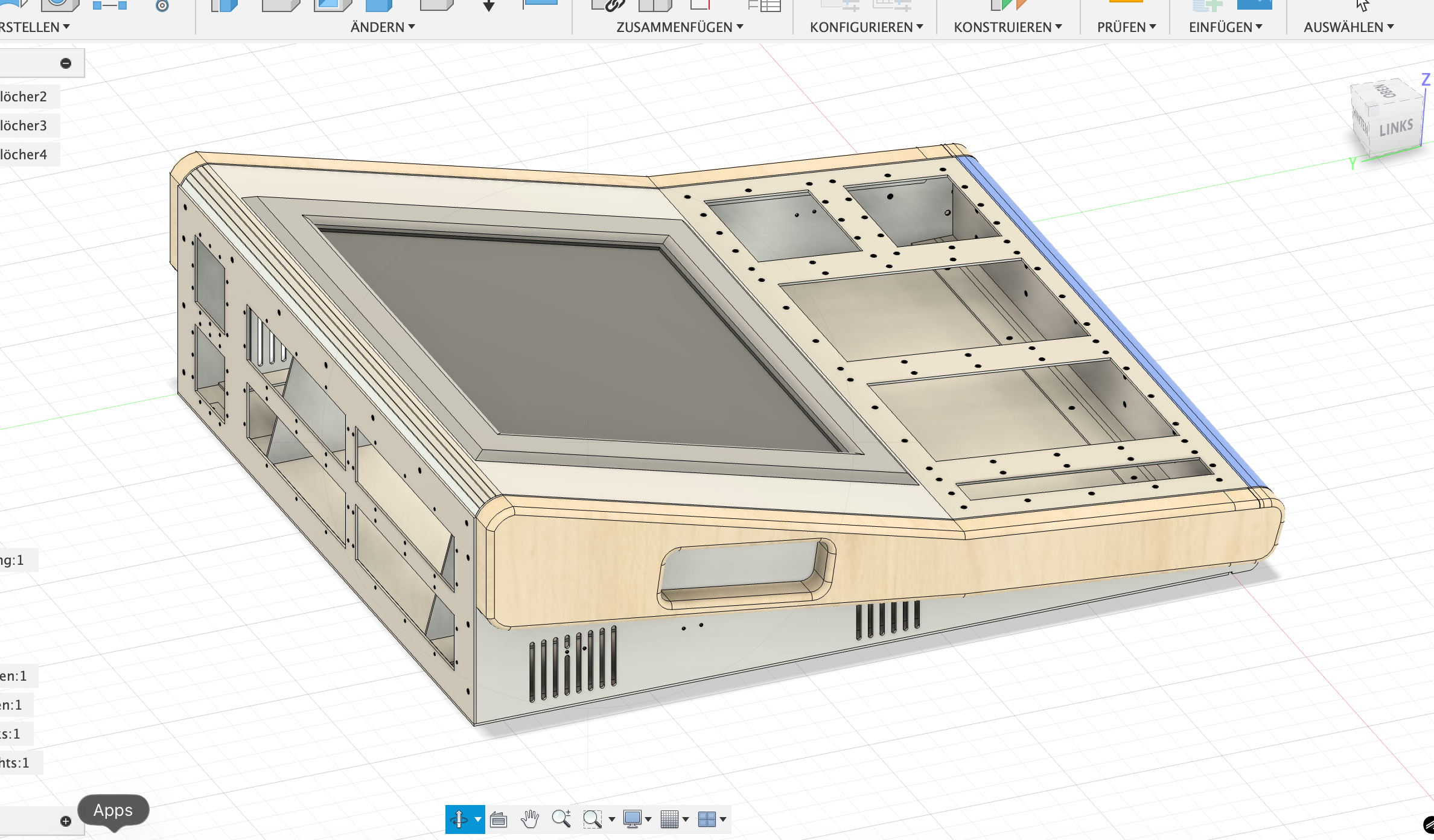

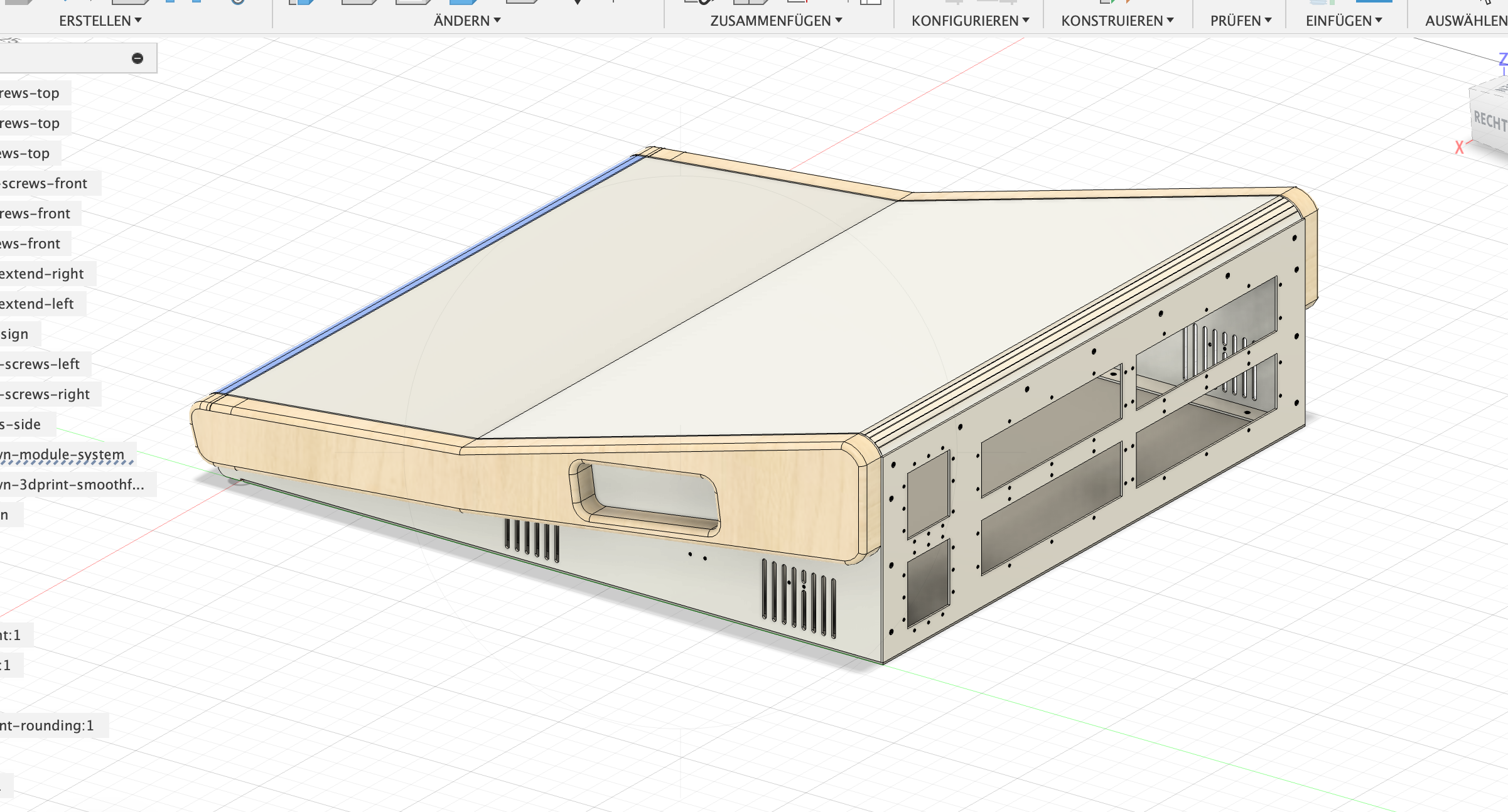

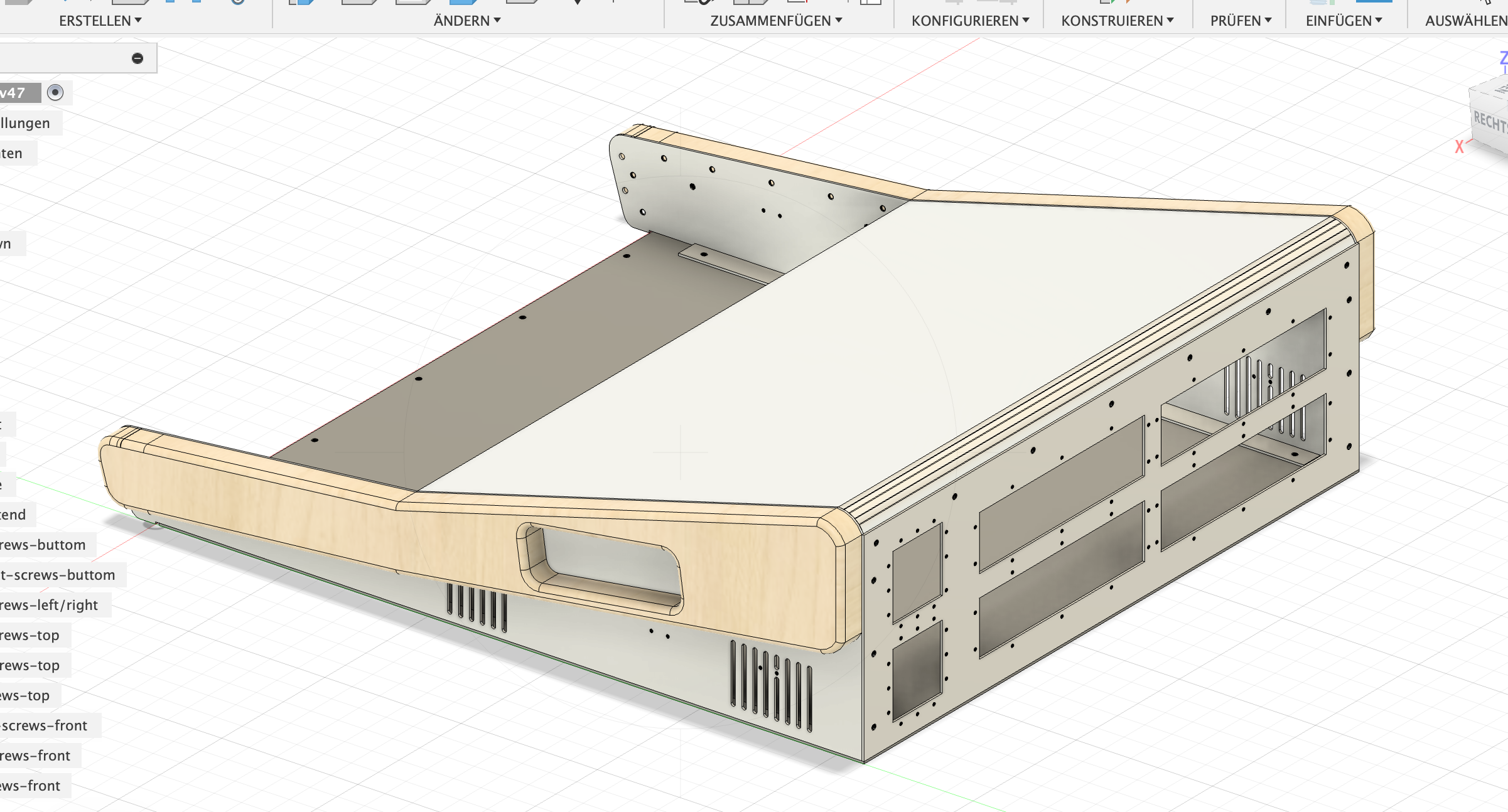

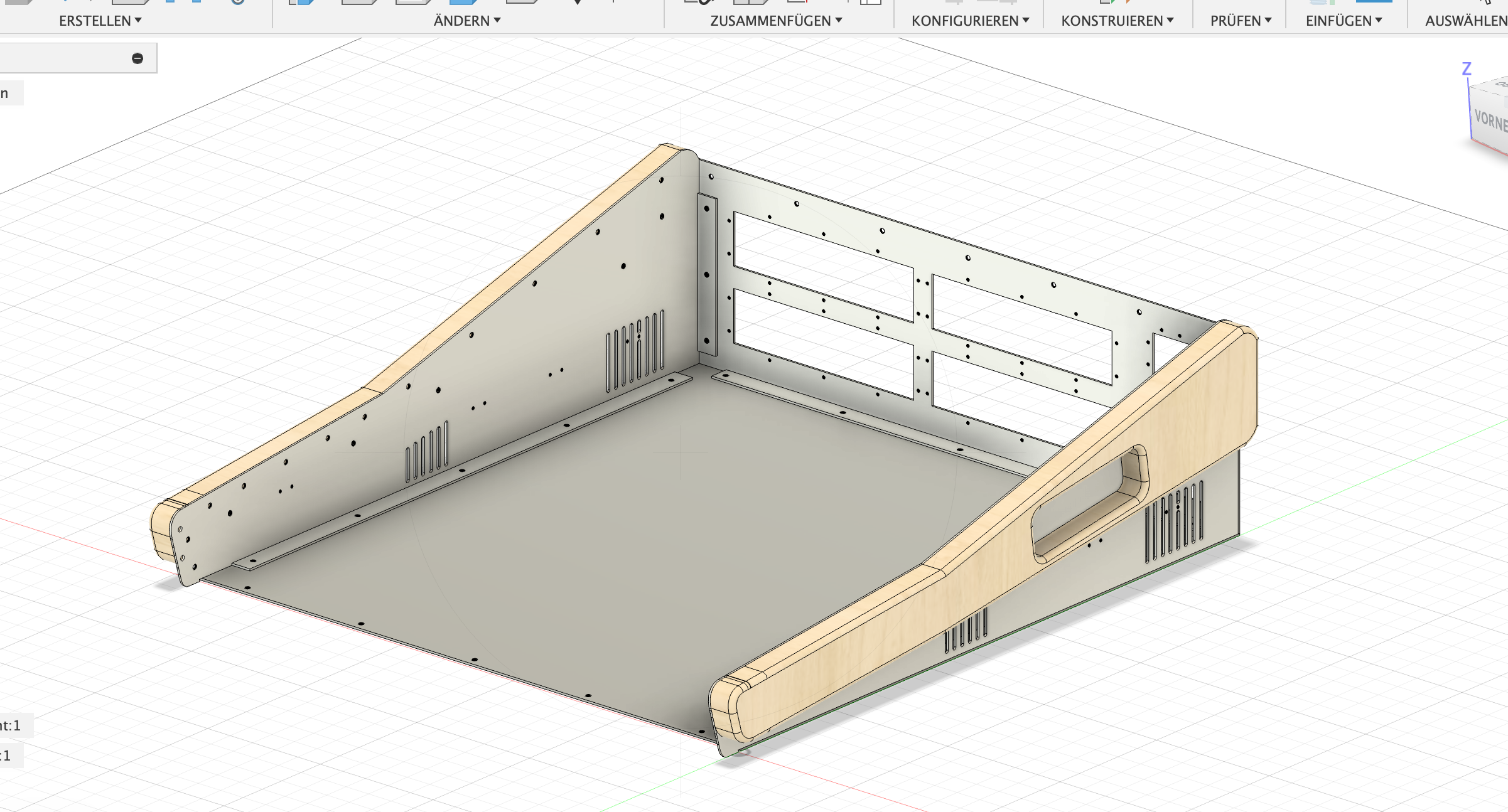

Big Screen + another module system

The next day brings new ideas and milestones. I'm on a five-hour drive today and am making good use of the time. This morning I finished the modular system for faders, knobs, keyboards, and everything else you can imagine for the console. On the left is a narrow module for knobs, next to it are two identical larger ones for example for faders and on the right are two smaller, stacked square modules for various other functions. I'll finish the individual modules and populate them as needed, so everyone can then create their own.

I also marked the dimensions for a large screen on the slightly raised section of the chassis and started modeling a mount for it. I initially considered 3D printing, but unfortunately, the display panel is too heavy for that, so I'll have to use 2mm sheet metal again. Now you're probably wondering why I didn't use a lighter display. Good question, but with this project, I also want to give old things a new lease on life, which I highly recommend. The display panel is from one of my old monitors with a broken driver board, so why not use something else and save money at the same time? Here's the current status:

the second module system:

And the display module at the top of the desk without a bracket, I'll do that next:

![]() Kian

added to the journal ago

Kian

added to the journal ago

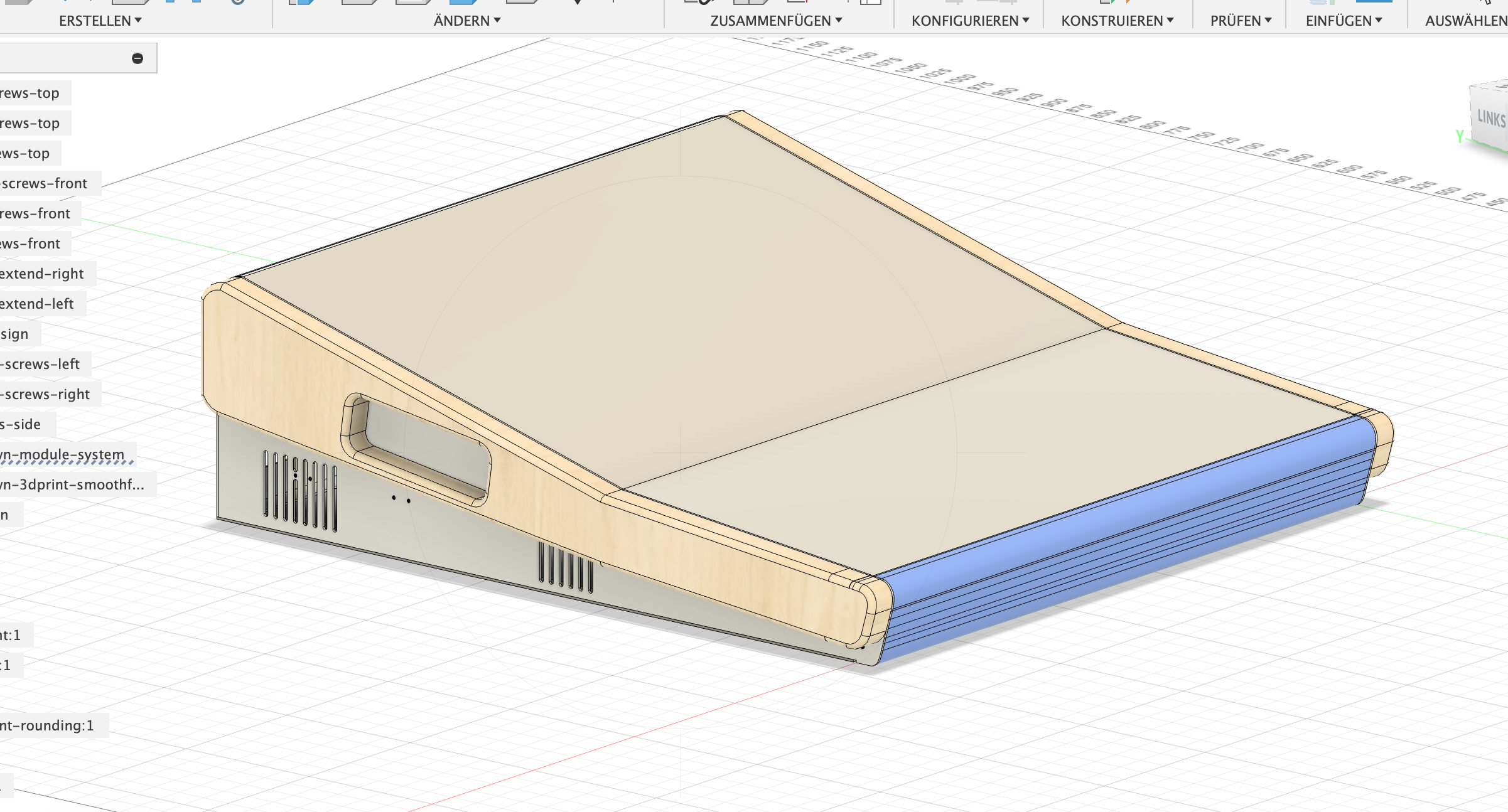

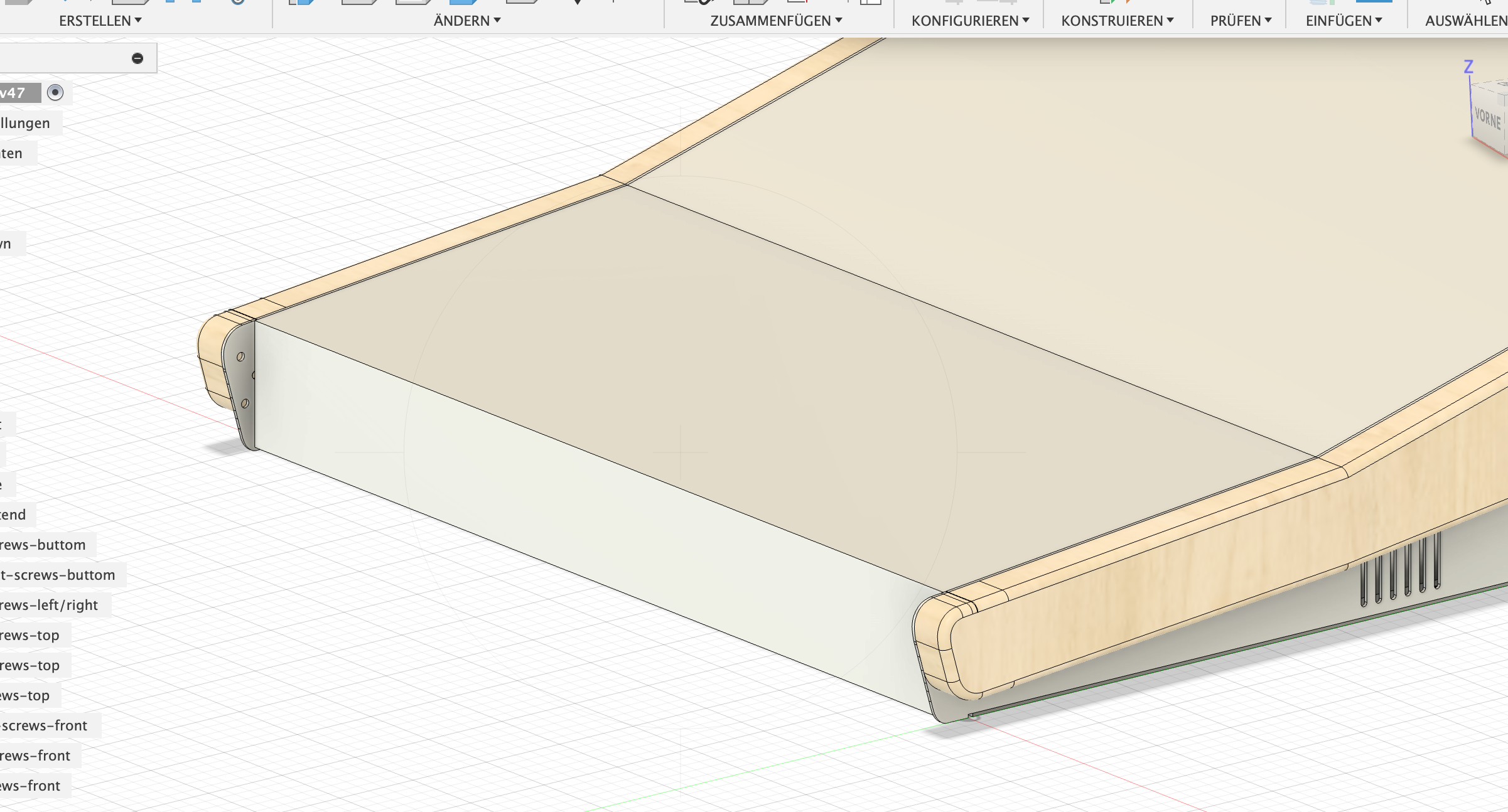

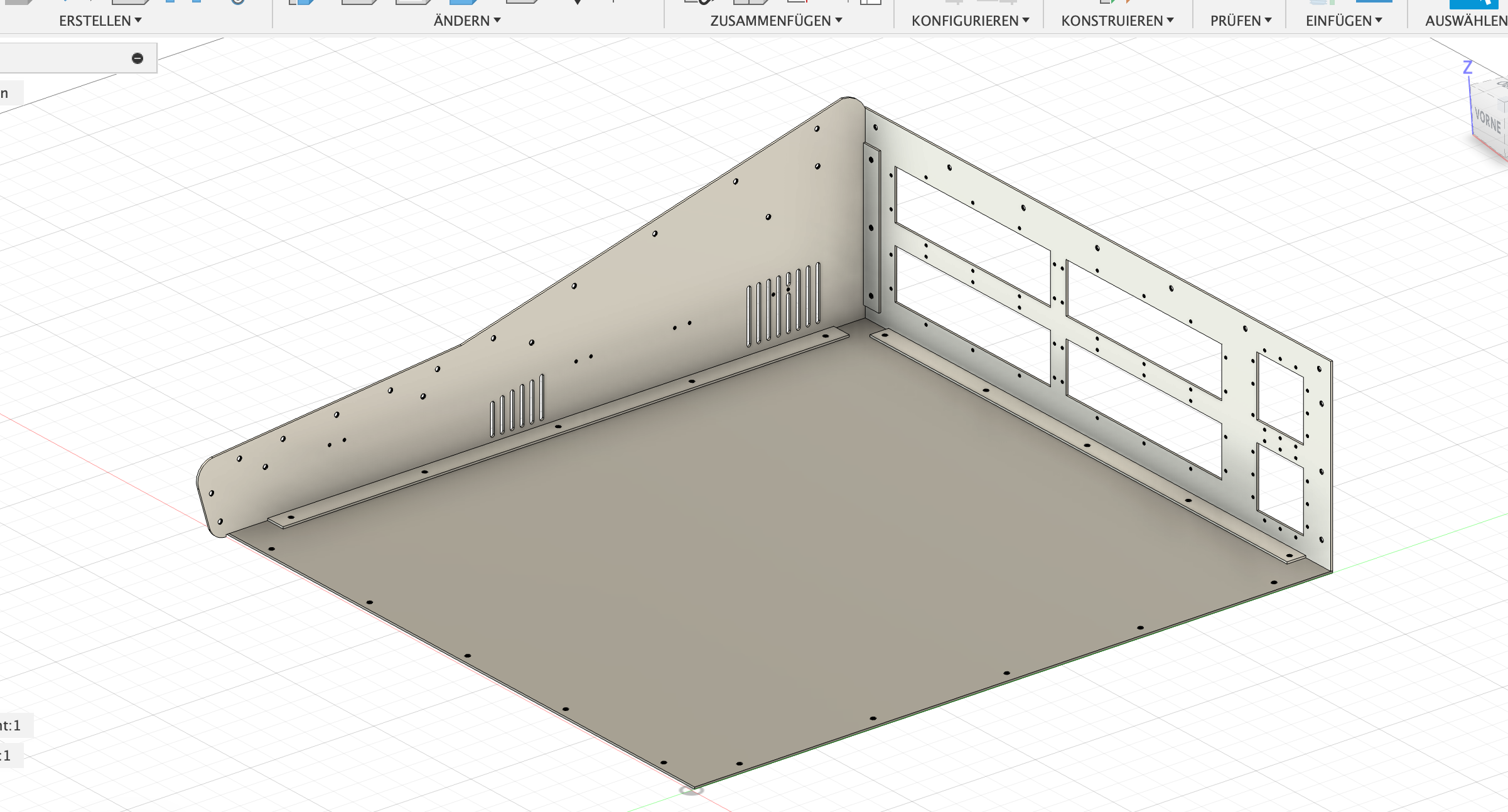

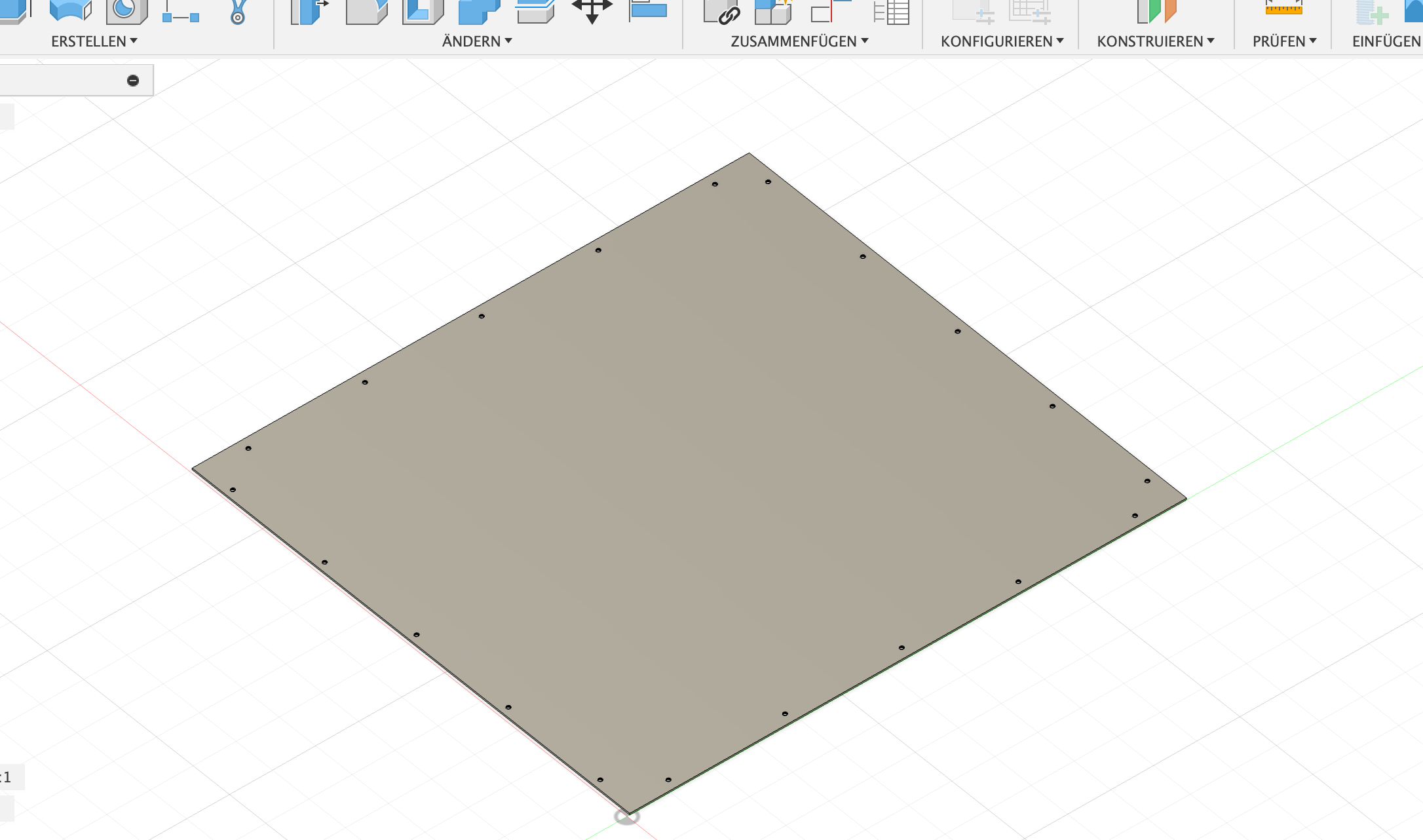

Top-Layer + first 3d printed parts

So, the last few hours haven't been that exciting. I finished the top panels, but I haven't done the panel system like the one at the back yet. The top panel is divided into two sections, and the bottom one is folded flat twice and then screwed to the base plate. As always, everything is secured with M5 screws or threads. Before I add the photos, let's look at the first 3D-printed parts I've modeled. The bottom rounded section is 3D-printed and can be customized with different colors. For example, you could have two or more desks with different accent colors... or just one in your favorite color, or simply a plain gray. The user can decide. The plan is to either make the modules the same color as the aluminum for just a single accent color, or to print everything in one color for a full, striking effect. Anything is possible. Here's the current status.

A picture from behind:

and two more random photos from the process:

![]() Kian

added to the journal ago

Kian

added to the journal ago

Finish sides + wood aesthetics

Alright guys, the right side panel is also finished and identical to the left one (as expected). I'm not a fan of large ventilation openings, the two small ones on each side should be sufficient, especially with an internal fan. Anyone needing more airflow can use both sides as intakes and add a large panel on the back for exhaust, or vice versa. I'll make the 3D printing templates for the rear modules soon, so everyone can build whatever they need from it.

Ohhh, what's that? Extensions for the sides of the chassis?! Made of wood of course, to add some aesthetics and practically to raise the whole thing. To save costs, I thought you could just screw/glue bits of any wood together, cut out the layout, and then sand the sides and handle round. That way, anyone can build it without expensive equipment and materials.

![]() Kian

added to the journal ago

Kian

added to the journal ago

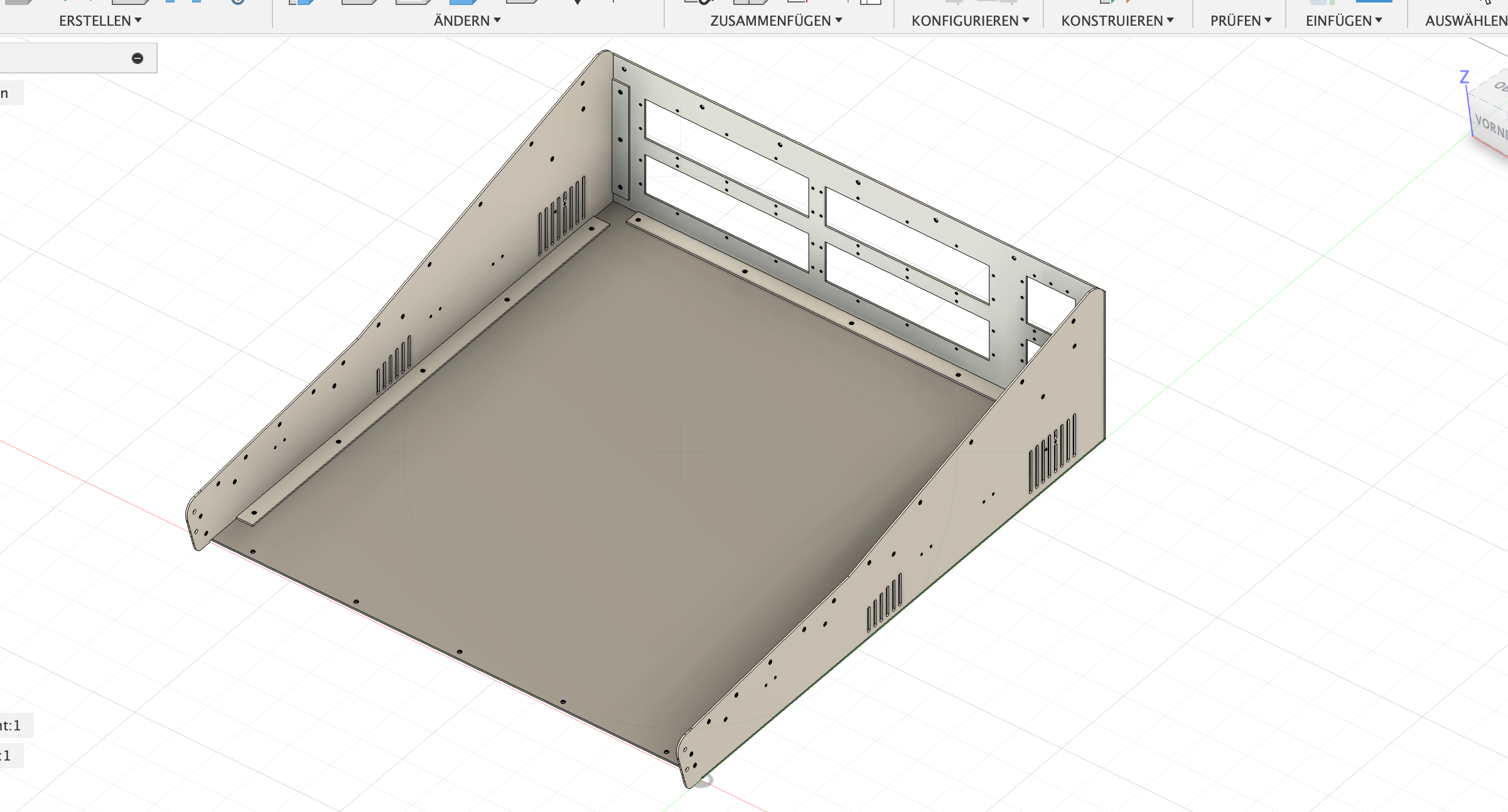

first side panel + surface finish

Here I am again. I spent last night and the rest of this morning building the left side panel. The final shape of the chassis is based on the Presonos Studio Live series, meaning it's slightly raised at the top to ensure a good view of the knobs and, most importantly, displays. Here's a photo:

Here again M5 screws are used for connecting the panels to each other, and several times in between, there are two M3 threaded holes for attaching things inside. I haven't thought about what I'll do with them yet, but having lots of options is always good, and I can drill into the base plate myself later. Drilling into the other panels would be more difficult. Of course, there are also ventilation slots.

Those who look closely will notice five more M5 holes that seem a bit out of place. To make the whole thing look nicer and easier to lift, I was thinking of adding wooden "extensions" to both sides. We'll get to that later.

And now to the surface finish. JLCNC has very good options for surface finishes, I would prefer powder coating as, according to my research, it's cheaper and more environmentally friendly than anodizing. Not important for now, but matte black would look nice :-)

![]() Kian

added to the journal ago

Kian

added to the journal ago

back panel + idea

Sooooo I'm back again, the rear panel is finished. I decided to screw everything together with M5 screws and attach the modules at the back with M3 screws to save space and to break it up a bit. And now, a photo:

There are two square modules for power inputs/passages, switches, and similar components, as well as four large, elongated spaces for sockets and anything else you might want. The large modules are 200mm long and fit on any standard 3D printer bed, the smaller ones fit even better. I'll postpone designing the example modules until later, tonight and tomorrow I'll finish the left and right panels, and hopefully the top one as well.

![]() Kian

added to the journal ago

Kian

added to the journal ago

dream + concept

I have a dream: a self-designed system where everyone can build the perfect mixing console/video console/DIY whatever console out of Aluminum Sheet Metal and a bit of the best hoppyist in house fabrication, 3d printing!

And if I manage to do it in time, also with custom PCBs, equipped with the LumenPNP! And eventually with my custom designed 3d printer the Kiloan-P1M :-)

For now, I'll start with the basic aluminum plate, which I'll buy individually and unmachined, and drill the holes myself to save costs. Then I'll work my way around it using Fusion 360 and create all the metal plates.

Here's to a sleepless night!

![]() Kian

started Kiloan Console ago

Kian

started Kiloan Console ago