Papa belt

AWD Belted 3d printer, inspired by parts of the babybelt, like the bed being made of iron on patches. but the printers is also optimized for speed and price, this is done through using voron 0 family parts like the bed and x gantry beam

Created by

![]() William 🚀

William 🚀

15 views

1 follower

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

throwing together the toolhead

i threw together a rough mock of of what sort of position the tool head would be in so i can better anticipate issues i might encounter

as mentioned in the previous journal, ive settled on a variant of the lancer because its geometry seems to work well for an angled belt printer

but there are 3 different lengths

i think the longest one will be the best because

- it has the highest flowrate, which is always nice

- it also is overhangs to the other side of the rail which might help the CG

started throwing together the tool head.

current i would guess the center of the gravity is where the blue cross is, i want it to be where the red cross is.

i want the center of gravity as close to the linear rail, and over the top of it if possible

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

fusion issues and hotend selection

I keep running into issues with fusion not being able to solve my constraints, so im considering deleting all the constraints and making them all again so i dont accidentally over constrain things or create conflicting constraints.

I had originally planned to use a modified dragon Hf, however due to cost and practicality issues ive chosen to use a different hot end

at an angle of 45 degrees the Peopoly lancer long just about clears the heater block

however at 40 degrees the clearance is much comfier so i will use 40 degrees

i was also thinking about how to set the angle of the gantry, i will probably use 3d printed parts so you can more easily remove the gantry or reprint those parts and change the angle of the gantry

i think from the following photo you can tell ive had a "fun" time with constraints

but i did add a double shear rigid motor mount for the two front motors .

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

more gantry+how did it take me 5 years to discover this

its taken me 5 years to realize that you could group sketches and construction things instead of just dealing with a massive list of things

started aligning all the stuff properly

i dont think i aligned it all well enough though.

i dont think i aligned it all well enough though.

currently getting super small angles between things and the X beam which isnt very good at all.

trying to problem solve this.

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

starting the moving part of the gantry

started off by fixing some joints and relationships

realized that i should move the two plates for the x beam closer together, before they were 22mm apart

by moving them 1mm close on each side i make the gap 20mm. which means that it will perfectly hold a 2020 extrusion

still a lot more work to do on this front

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

more gantry work

both of the pulleys for the belts now fit properly in the double shear tensioners

i think the next step is going to be modelling the stuff to support the idlers next

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

almost forgot to replace all the screws

replaced all the m3x40 with m3x45

because my screws were 5mm longer, but i "only" added 4mm in the middle, to avoid the screws going into the motor to deep, or into anything else too far, i extruded all the surfaces on the top plate up by 1mm. which takes it up to 6mm thick.

im slightly worried the 5mm thickness of the bottom plate isn't enough. but only time will tell.

turns out an old sketch wasn't properly constrained.

moving backwards in the timeline was fine, but moving forwards for some reason is incredibly laggy and causes fusion to freeze and me to ultimately need to end the process with task manager.

i fixed the issue of the angle by just remaking it, i repositioned the screws that held it together and made the thread shorter since it really didn't need to be that long given its only moving 5mm.

also had to reconstruct the joints and relationships to get it to all properly move again

this took a lot longer that i expect, but it needed to be done.

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

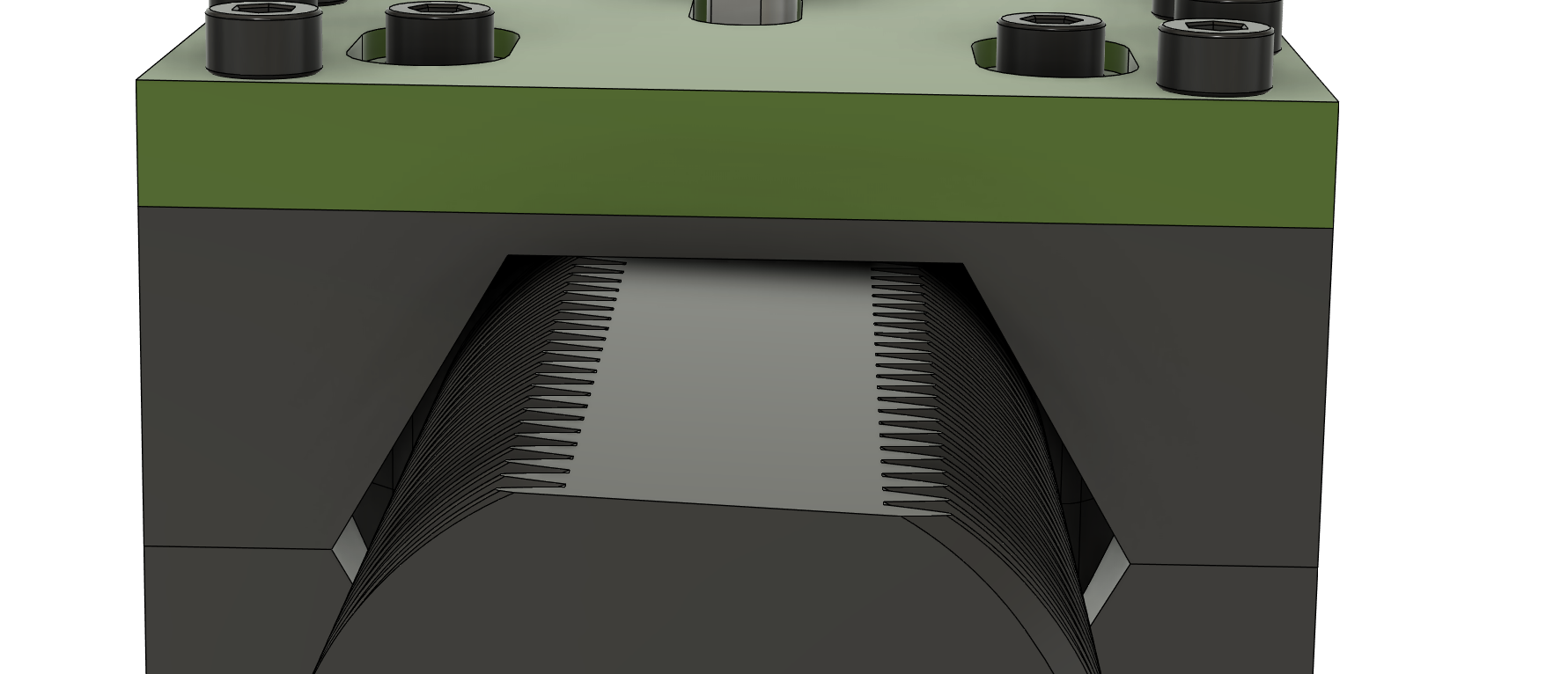

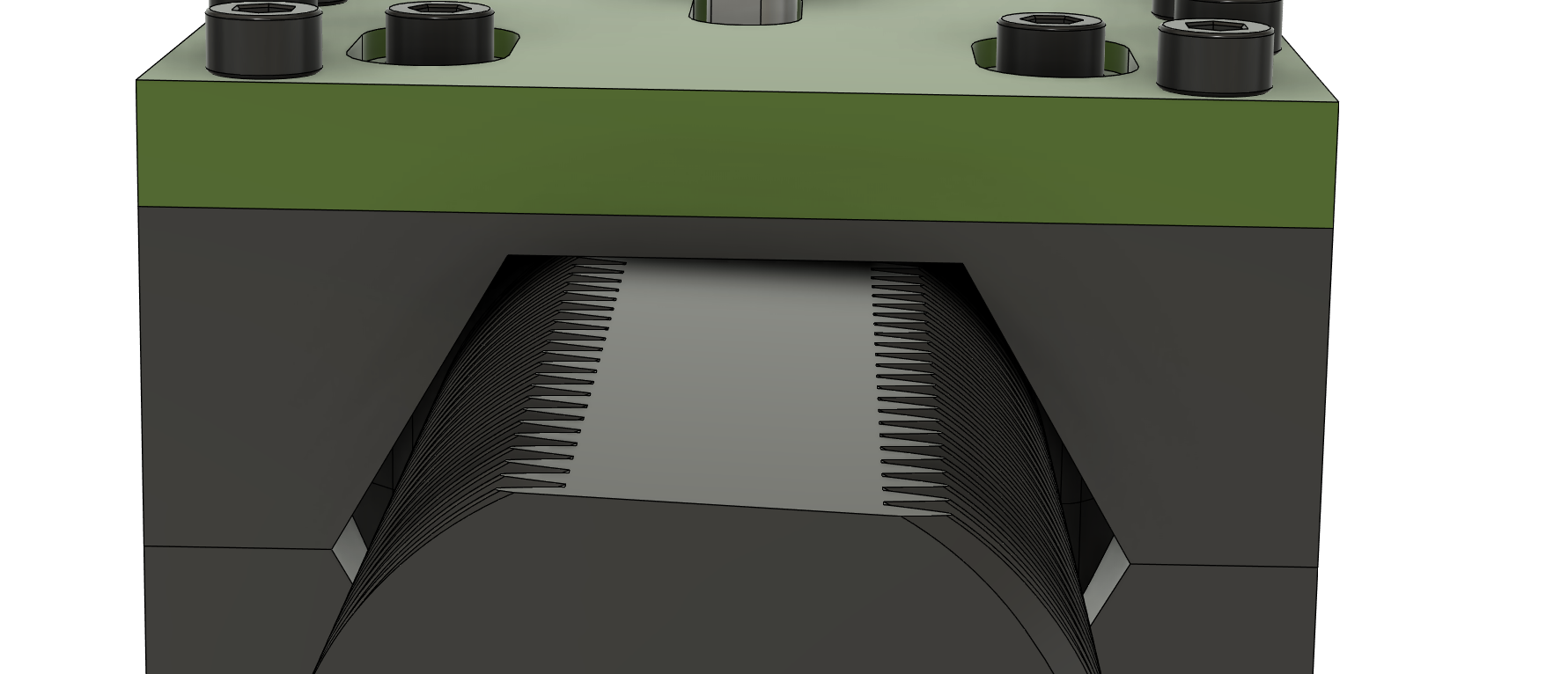

fixed the motor offset thing

so i work out a way to sort out the motor issue while keeping things printable

First i cut the threaded part off the tensioner

then i moved each of the tensioner halves 2mm away from the central plane

which created a 4mm gap

which i filled in by extending each of the halves by 2mm

however now printing the parts looks tricky

because the whole thread part will overhang

so i slice off that 2mm pieces at the top and bottom

because i already have screws going through everything

it should all just align as part of the stack

ive also just chopped the central part of the housing in half

but i dont like how the printability looks

it looks better split in half

hopefully all of the splitting up doesn't affect the rigidity, the m3x45 bolts should be able to hold it all together tightly and help.

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

placing motors

put the motors tensioners into place.

I also created joints and rigid bodies for the tensioners

there is an issue however.

the motors aren't level

they are 3.9mm out of being level

so thats an issue.

im not quite sure how to fix it since i dont want to use even longer screws

m3x45 feels TOOOO long, and probably expensive.

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

finishing off the tensioners

the more i work through the idea of moving the motors, the more i question if it was a good idea.

Realizing that i need 12, m3x40 bolts per tensioner, so 24 , m3x40 bolts really made me question it given m3 bolts that long are pricey (around $3 for 50).

I say "need 12", however the 8 holding the casing together could be replaced with shorter m3x8 or m3x12 bolts, and bolting the top part to the middle, and the middle to the bottom, however i feel that having a bolt going all the way through, compressing the layers should be better for strength.

thinking about it more, smaller bolts double the number of heat sets, and bolts, so even if the bolts are cheaper the price difference might still be negligible.

Either way, im sticking with the long bolts.

However i want to get this done before dec 31st so I'm sticking with the design that I'm more comfortable with.

I also just prefer to have moving motors.

(the above statement may be copium)

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

did more work on the gantry

ive done a bunch of work on the gantry and now all the blets and idlers are moving and scaling properly when you change the parameters.

i made the gantry parametric so you should be able to scale the printer up or down which was one of the design goals

also starting putting some work into designing the belt tensioner

im aware that moving the idlers is better for input shaper values, however i much prefer moving the motors. for small printers i find that moving the idlers can be difficult due to the space constraints

there was also a chunk of problem solving in trying to get the gantry scaling parametrically.

it turns out the move tool in fusion doesn't like working parametrically, nor does the align tool.

however if you use the "constrain components" tool, and pick align in there, it does work properly with parametric stuff.

:face-palm:

i already had everything as components so nothing changed apart from now i was using the align tool within a different menu.

how fun.

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

more work on belt path

actually properly implemented the belt path, it definitely feels challenging, probably because I've never designed a core XY gantry from scratch before.

but i recon once i get past this stage it should rapidly speed up because I've designed all other parts at least once.

![]() William 🚀

added to the journal ago

William 🚀

added to the journal ago

Sttarting

i started a BOM so that i can keep track of price

i started by looking at how i wanted to arrange things a bit.

then it came to the thing im most scared of, the belt path.

At first it seemed super magical and intimidating

so i decided to draw out the beltpath for the monolith gantry and see how that worked

which helped me realise some of the relationships and dimensions etc

so then i could draw out this and use this to start doing something in CAD

ive tried to keep everything parametric so that i could make the printer bigger if i wanted, perhaps 180mm^2 instead of the current plan of 120mm^2

it does look like a bit of a mess but hopefully it can still come together nicely

![]() William 🚀

started Papa belt ago

William 🚀

started Papa belt ago

12/15/2025 - Sttarting

i started a BOM so that i can keep track of price

i started by looking at how i wanted to arrange things a bit.

then it came to the thing im most scared of, the belt path.

At first it seemed super magical and intimidating

so i decided to draw out the beltpath for the monolith gantry and see how that worked

which helped me realise some of the relationships and dimensions etc

so then i could draw out this and use this to start doing something in CAD

ive tried to keep everything parametric so that i could make the printer bigger if i wanted, perhaps 180mm^2 instead of the current plan of 120mm^2

it does look like a bit of a mess but hopefully it can still come together nicely

12/20/2025 - more work on belt path

actually properly implemented the belt path, it definitely feels challenging, probably because I've never designed a core XY gantry from scratch before.

but i recon once i get past this stage it should rapidly speed up because I've designed all other parts at least once.

12/27/2025 - did more work on the gantry

ive done a bunch of work on the gantry and now all the blets and idlers are moving and scaling properly when you change the parameters.

i made the gantry parametric so you should be able to scale the printer up or down which was one of the design goals

also starting putting some work into designing the belt tensioner

im aware that moving the idlers is better for input shaper values, however i much prefer moving the motors. for small printers i find that moving the idlers can be difficult due to the space constraints

there was also a chunk of problem solving in trying to get the gantry scaling parametrically.

it turns out the move tool in fusion doesn't like working parametrically, nor does the align tool.

however if you use the "constrain components" tool, and pick align in there, it does work properly with parametric stuff.

:face-palm:

i already had everything as components so nothing changed apart from now i was using the align tool within a different menu.

how fun.

12/28/2025 3 AM - finishing off the tensioners

the more i work through the idea of moving the motors, the more i question if it was a good idea.

Realizing that i need 12, m3x40 bolts per tensioner, so 24 , m3x40 bolts really made me question it given m3 bolts that long are pricey (around $3 for 50).

I say "need 12", however the 8 holding the casing together could be replaced with shorter m3x8 or m3x12 bolts, and bolting the top part to the middle, and the middle to the bottom, however i feel that having a bolt going all the way through, compressing the layers should be better for strength.

thinking about it more, smaller bolts double the number of heat sets, and bolts, so even if the bolts are cheaper the price difference might still be negligible.

Either way, im sticking with the long bolts.

However i want to get this done before dec 31st so I'm sticking with the design that I'm more comfortable with.

I also just prefer to have moving motors.

(the above statement may be copium)

12/28/2025 5 AM - placing motors

put the motors tensioners into place.

I also created joints and rigid bodies for the tensioners

there is an issue however.

the motors aren't level

they are 3.9mm out of being level

so thats an issue.

im not quite sure how to fix it since i dont want to use even longer screws

m3x45 feels TOOOO long, and probably expensive.

12/28/2025 3 PM - fixed the motor offset thing

so i work out a way to sort out the motor issue while keeping things printable

First i cut the threaded part off the tensioner

then i moved each of the tensioner halves 2mm away from the central plane

which created a 4mm gap

which i filled in by extending each of the halves by 2mm

however now printing the parts looks tricky

because the whole thread part will overhang

so i slice off that 2mm pieces at the top and bottom

because i already have screws going through everything

it should all just align as part of the stack

ive also just chopped the central part of the housing in half

but i dont like how the printability looks

it looks better split in half

hopefully all of the splitting up doesn't affect the rigidity, the m3x45 bolts should be able to hold it all together tightly and help.

12/28/2025 5 PM - almost forgot to replace all the screws

replaced all the m3x40 with m3x45

because my screws were 5mm longer, but i "only" added 4mm in the middle, to avoid the screws going into the motor to deep, or into anything else too far, i extruded all the surfaces on the top plate up by 1mm. which takes it up to 6mm thick.

im slightly worried the 5mm thickness of the bottom plate isn't enough. but only time will tell.

turns out an old sketch wasn't properly constrained.

moving backwards in the timeline was fine, but moving forwards for some reason is incredibly laggy and causes fusion to freeze and me to ultimately need to end the process with task manager.

i fixed the issue of the angle by just remaking it, i repositioned the screws that held it together and made the thread shorter since it really didn't need to be that long given its only moving 5mm.

also had to reconstruct the joints and relationships to get it to all properly move again

this took a lot longer that i expect, but it needed to be done.

12/28/2025 10 PM - more gantry work

both of the pulleys for the belts now fit properly in the double shear tensioners

i think the next step is going to be modelling the stuff to support the idlers next

12/29/2025 - starting the moving part of the gantry

started off by fixing some joints and relationships

realized that i should move the two plates for the x beam closer together, before they were 22mm apart

by moving them 1mm close on each side i make the gap 20mm. which means that it will perfectly hold a 2020 extrusion

still a lot more work to do on this front

12/31/2025 - more gantry+how did it take me 5 years to discover this

its taken me 5 years to realize that you could group sketches and construction things instead of just dealing with a massive list of things

started aligning all the stuff properly

i dont think i aligned it all well enough though.

i dont think i aligned it all well enough though.

currently getting super small angles between things and the X beam which isnt very good at all.

trying to problem solve this.

1/5/2026 - fusion issues and hotend selection

I keep running into issues with fusion not being able to solve my constraints, so im considering deleting all the constraints and making them all again so i dont accidentally over constrain things or create conflicting constraints.

I had originally planned to use a modified dragon Hf, however due to cost and practicality issues ive chosen to use a different hot end

at an angle of 45 degrees the Peopoly lancer long just about clears the heater block

however at 40 degrees the clearance is much comfier so i will use 40 degrees

i was also thinking about how to set the angle of the gantry, i will probably use 3d printed parts so you can more easily remove the gantry or reprint those parts and change the angle of the gantry

i think from the following photo you can tell ive had a "fun" time with constraints

but i did add a double shear rigid motor mount for the two front motors .

1/7/2026 - throwing together the toolhead

i threw together a rough mock of of what sort of position the tool head would be in so i can better anticipate issues i might encounter

as mentioned in the previous journal, ive settled on a variant of the lancer because its geometry seems to work well for an angled belt printer

but there are 3 different lengths

i think the longest one will be the best because

- it has the highest flowrate, which is always nice

- it also is overhangs to the other side of the rail which might help the CG

started throwing together the tool head.

current i would guess the center of the gravity is where the blue cross is, i want it to be where the red cross is.

i want the center of gravity as close to the linear rail, and over the top of it if possible