Ender 3 revamp

Some badly needed upgrades to keep my ender 3 v2 on par with modern printers like the A1. Octoprint running on a orange pi 0 allows for wireless printing, print failure detection running locally, and an h2d inspired LED progress bar and task light. The repo has it all explained :)

Created by

![]() Jake Hopkins 🚀

Jake Hopkins 🚀

Tier 4

2 views

0 followers

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Soldering and pre assembly

This took so, so much longer than I expected, but I'm starting to realize that even simple soldering and assembly takes a long time. Before I had soldered the leads of the LED strip to jumper cables so that I could easily test them with my raspberry pi, but this didn't work well with the final iteration of my design (which I printed out last night).

I realized that it made more sense to cut the strip, and use separate section for both the status indicator and the task light. I was sacred to cut the LED's, even though the strip shows you where to cut it. Cutting it went fine, but I then had to cut open all my connections to add in the 3rd wire for the second strip. This way they both share gnd and 5v power. The DIN leads are separate though, and connected to GPIO 18 and 19. I then put little heat shrink tubes around the wires to that there was no bare metal showing.

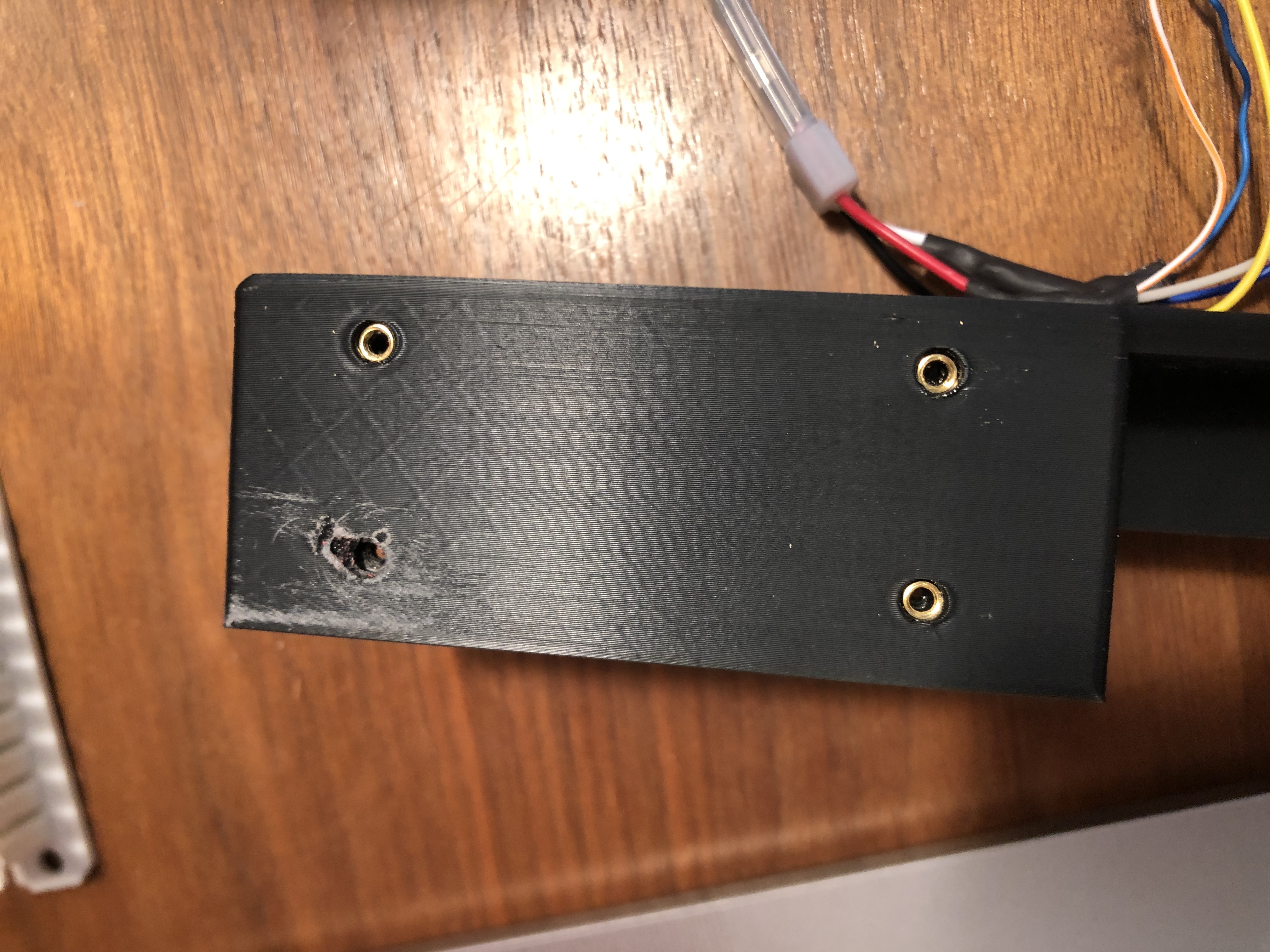

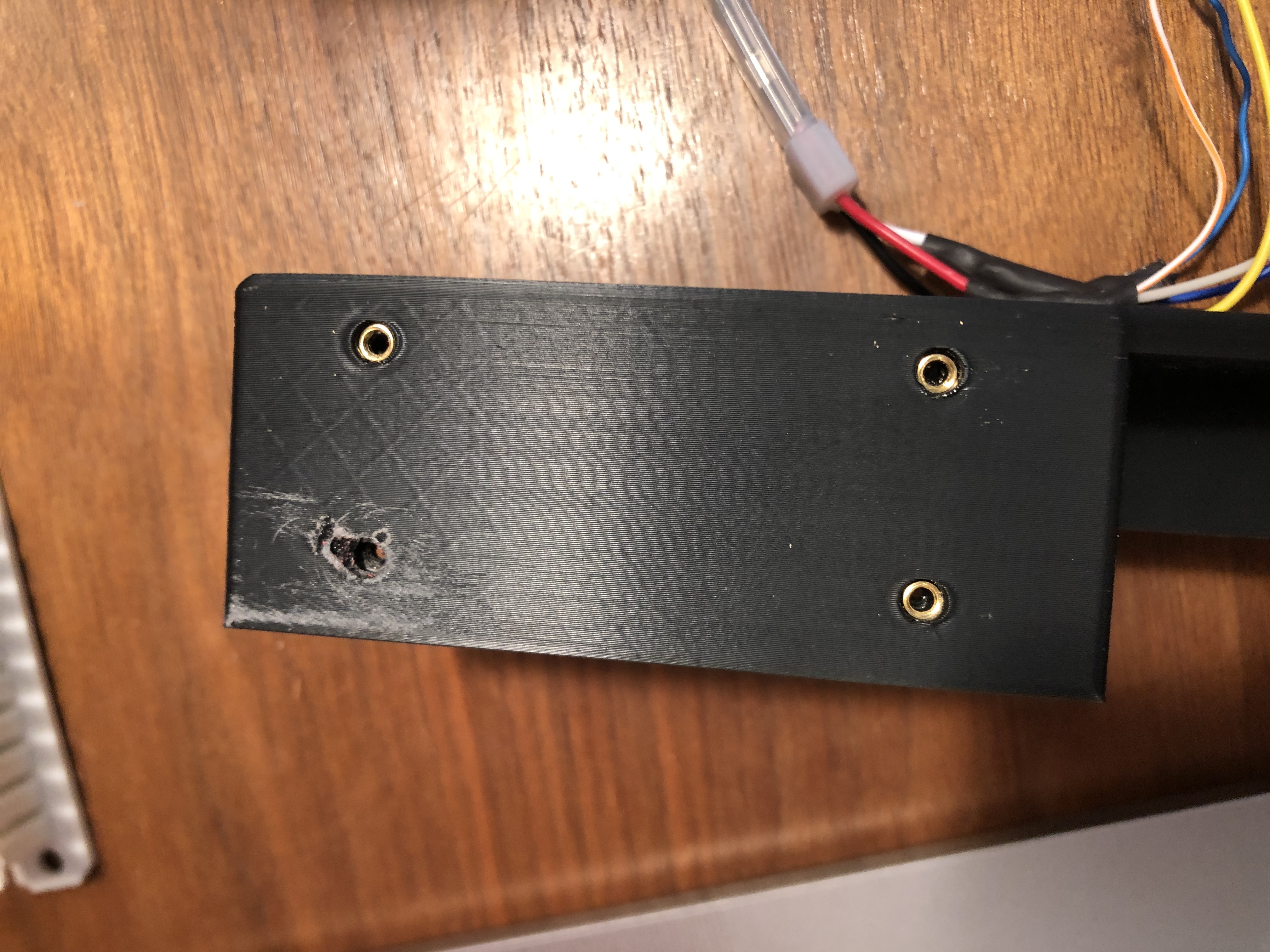

I then added my heat set inserts that will keep the rpi in place. Tip, if your holding iron is super hot, you can use a leaf blower to instantly cool it down to change the tips :). The tolerances for the inserts must of been looser than normal, because 2 of them started spinning when I inserted a screw, so I had to yank them out with a combination of heat and force. The tried putting one back in, and I pushed them all in more, so hopefully they hold the super small amount of weight.!

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Revised the CAD

Last night I printed out my parts, and realized that it could be a lot more streamlined of a design. I updated the design so that all the components are in one solid part, instead of having a separate enclosure for the pi. I also changed it so that the pi bolts onto the part instead of just floating in a box. I also realized my tolerances were way too tight for the LED strip, so I added an extra 1mm of padding around the cutout.

I'll print this version out tonight, and hopefully everything will work well!

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Octopi VPN

Because octopi runs locally on a raspberry pi, its UI is only LAN accessible. This was to large of a compromise for me, because I want to be able to monitor and start prints from anywhere. There are a lot of plugins to forward your ocotprint website through your router so that it can be assessable anywhere, but they all come with a scary amount of warnings telling of the dangers of hackers.

From what I could tell, the safest option is a locally ran vpn. When you connect to it, you are essentially on your home network, allowing you to connect to LAN devices. The easiest option to do this is with PiVPN. I am running this on my pi 5 that is always on, since it's quite a but faster than the octoprint pi 0 and won't be competing with ocotprint compute this way.

Setting up PiVPN over the CLI was fairly straightforward, although there was a lot of vocab I didn't know. I then set up port forwarding on my router, which was tricky because of the ridiculous amount of menu nesting I the app. Finally I downloaded wireguard on my Mac and imported the config file from my pi. Here is what the UI looks like.

Because the pi isn't connected over ethernet, the speeds aren't great, about 15mbs. Because it's so slow I don't leave it on all the time, but for connecting to octoprint and getting past my schools wifi bans it gets the jobs done, and I've even accidnatly joined zoom meetings on it and it handles it's self until alright

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Wrote software

A key part of my project is the neopixels lights, which can be controlled with an amazing amount of control. I used the adabfruit blinks library, and followed the official Adafruit tutorial to get the basics of the library. I then got an API key from my pi's octoprint, and connected the ip address of the pi for the script to listen to the print status.

The code is fairly simple. When printing, it turns on the task light, and the progress bar with the print progress. When idle it lights up the task light, and pulses the progress bar green. When a print is finished the progress bar is solid green. If there is an error, it flashes the lights red. Also between 10pm and 7am I'm asleep, so it turns off the lights during those times. Hackatime tracked an hour and 2 minutes.

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Set up octopi!

When I opened up the rpi imager, it said there was a new update, so I went ahead and got the new version of that, and I really like the fresh UI. It took about 15 minutes to write the OS, and this was mainly limited by the slow read write speed of the sd card(15 mbs). I used the octopi image preset in the rpi imager, which is just pi os with octo pi installed.

As soon as I ssh'd into the pi it gave instruction for the website for octoprint(ran locally on the pi). I went through the set up wizard and used the dimensions and heater limits for my ender 3 v2 neo. I was worried about something failing, which I don't know why, because octoprint is just as safe as sd card printing. Turns out you can't use the pi during prints though(learned that the hard way).

I really like the octoprint UI, but I'm defiantly going to tryout some plugins to for dark mode.

![]() CAN ⚡🚀

approved Ender 3 revamp ago

CAN ⚡🚀

approved Ender 3 revamp ago

Tier approved: 4

Grant approved: $52.00

Nice project.

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Found a new power supply

The current power supply for the raspberyr pi was to espesnisve at 7 dollars, so I found a replacement on aliexpress for 99 cents. Hoepfully it doesn't burn my house down💀

![]() NotARoomba 🚀

requested changes for Ender 3 revamp ago

NotARoomba 🚀

requested changes for Ender 3 revamp ago

Hey! I think this is a really cool project but could you try and get that wall adapter from Aliexpress as well? Aside from that, nice work!

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Added detail

Basically I just went back into my previous journals that were lacking detail and explained in more depth my design choices and how specific key parts will work. If I had to guess I'd say I added about 400-500 characters, not including images.

![]() Tanuki ⚡🚀

requested changes for Ender 3 revamp ago

Tanuki ⚡🚀

requested changes for Ender 3 revamp ago

Hello! This is so so cool! This seems really useful. Just have more depth in the journal, and I think its good to go :) As far as screenshots go, I only see the final product of the CAD.

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Explaining the features

Features:

-An LED task light!

The corner of my room that my ender 3 lives in, and past 4:30 pm(when I normally do my printing)it is hard to see anything thats going on, which makes it very hard to see print quality or errors, feed filament etc.

The LED task light uses some standard 24v white LED's that I have extras of from a past project. They will be powered by a 24v plug in power supply and go in a slot in the bottom of my LED enclosure(Shown below). It will simply be toggles on off by a switch in the power supply.

-Print progress bar!

One of the coolest features of Bambu Lab's new flagship printer, the H2d, is the LED progress bar on the side, which is way more convenient than looking at the tiny LCD display on the side of my printer. Mine will use 0.5 meter addressable neopixel LED strip cut down to length, that will be controlled via the Raspberry pi, using the octoprint API to determine how far along the print is done. The neopixel strip will be ordered from adafruit for $12.5( See BOM). The LED's will be masked by a 3d printed diffuser at 0% infill so that you can't see the individual LED's.

In the image above, this will go in the highlighted area labeled "neopixels will go here".

-Octopint!

Octoprint is awesome opensource software that runs on a raspberry pi and allows you to control any 3d printer remotely. It communicates to the 3d printer via the micro-usb port, so that you dont have to go into the guts of the printer, and it allows you to start and monitor prints from you computer, phone, or crappy school chromebook. All you need for it is a raspberry pi, cable, and sd card(See BOM). This will go in the picture below, which has the Raspberry pi modled into it's enclosure

.

-Camera for time elapses and print failure detection

Using the camera module 2 I already have from raspberry pi, I can uses octoprint to automatically take timealapses that have the toolhead home to the same spot each time, allowing for the fancy timealapses that you see on printers like the H2D. It also can locally run machine learning models that detect print failures, like the print coming loose, and send you an alert or stop the print autonomously. The camera will go into it's pictured slot in the pictured above, with a CSI ribbon cable connected to the raspberry pi. Like a said I chose this camera because I already have it on hand, and don't have to buy it.

P.S. This is my submission for Prototype, so please accept it, even if you want me to change a few minor things I will, I just really want to go to the hackathon :)

![]() nimit 🚀

requested changes for Ender 3 revamp ago

nimit 🚀

requested changes for Ender 3 revamp ago

This project has a lot of potential, great job on the CAD! But the exact revamp features are kind of confusing. Put yourself in the position of someone following your changes, and write some info on each mod you do (kind of like a guide!)

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Iamalive 🚀

requested changes for Ender 3 revamp ago

Iamalive 🚀

requested changes for Ender 3 revamp ago

You said you're making both a "LED task light to light up my print bed", and "LED NeoPixel print progress bar (like the H2D)" Then in your readme you said that you already had the LED light. Does this mean both LEDs are NeoPixels, which you have, or something else?

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

More explaing

People still can't seem to understand how my project works, which is fair. Maybe the stereotype about engineers being bad communicators is true:) I added 4 more angles, with more annotations from my iPad, and I'm going to explain them, so hopefully they make more sense after reading this.

Below is a zoomed out view of how it all works. there is a green piece I will 3d print that has the Rpi and camera(annotated). This will mount with m3 screws to the top extrusion of the ender 3.

Below is a zoomed in view of the LED assembly(in pink). It also mounts to the top extrusion of the ender 3. It has slots for both the addressable neopixels and the bright 24v white tasklight LED's.

Below is a zoomed in view of the electronics sub-assembly. It has the Rpi 03w, in green(annotated), and a arm to hold the camera(with m2.5 hardware). I drew in the ribbon cable because that kind of think doesn't work well in fusion, and I couldn't find a model for my camera, but I have an arrow showing where it will go(far left). This image is in gray to show the colors of the RPi, instead of the bright colors fusion generates to easily tell components apart.

Below is a zoomed out view of the electronics enclosure, showing how it fits in on a larger scale. It's a little confusing because one of the aluminum extrusions is also green, but this is NOT part of the design, and is a quirk of fusion. It has the same features metnioned above- the RPi, camera cable and spot for the camera. You can see that it mounts to the blue bar, which is the top of the Ender 3 gantry, and is also where the LED assembly will mount(Both will m2.5 hardware).

![]() Iamalive 🚀

requested changes for Ender 3 revamp ago

Iamalive 🚀

requested changes for Ender 3 revamp ago

Can you add seperate pictures of the two parts that you will attach to your ender in differnt angles? Also does this include the final render which has the parts you want to buy attached?

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Figured out the mounting

After getting feedback from a reviewer, I realized I needed to have my 3d printer inside the design so people could figure out what was going on. Even though I had the idea perfectly clear in my head, no else did, and things that I thought were obvious aren't in retrospect. I think that it's a clearer now. Both assemblies will mount to the 3d printer using m3 hardware onto the aluminum extrusion. I will slide T-nuts into the extrusion, then put the bolts through the 3d printed part ad the T-nut, which is how my filament holder is attached, and can hold over 1 kilogram, so I think that this will be plenty strong.

Adding in the chunking ender 3 step file really slowed down Fusion, so this part took longer than expected

![]() Tanuki ⚡🚀

requested changes for Ender 3 revamp ago

Tanuki ⚡🚀

requested changes for Ender 3 revamp ago

Hello! This is still hard to understand :sob: I think it would be optimal if you imported an Ender 3 and put it on that assembly to show how exactly it gets assembled onto an ender 3

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Tanuki ⚡🚀

requested changes for Ender 3 revamp ago

Tanuki ⚡🚀

requested changes for Ender 3 revamp ago

Hello! While the concept of this is cool, from your ReadME, its unclear how this will be incorporated into an Ender 3.

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Shaurya Bisht

requested changes for Ender 3 revamp ago

Shaurya Bisht

requested changes for Ender 3 revamp ago

Could you make a schematic or design of how you are going to incorporate all the components together?

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Shaurya Bisht

requested changes for Ender 3 revamp ago

Shaurya Bisht

requested changes for Ender 3 revamp ago

cart screenshots dont add up to grant request?

![]() Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

Jake Hopkins 🚀

submitted Ender 3 revamp for review ago

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

drafted it out

This morning I used fusion 360 to design out everything I will 3d print, while listening to Leon Bridges. I started with the LED enclosure that includes a mounting system to the top of my printer, a slot for the neopixel LED's behind a removable 3d printed diffuser, and an alcove at the bottom for the task light LED's.(thats the image in pink)

I then designed an electronics enclosure that would house the raspberry pi, rpi camera, and wires for the LED's. This part was a little trickier because I find that as designs get more complex and larger I have a harder time working on them.

I then polished everything off with a healthy splattering of filets.

Finally I send the images to my iPad where I annotated them so that it's clearer to see whats going on. For that I just used apples basic Markdown tool in photos.

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

Sourced the parts

The next thing I did was source the BOM. I knew that adafruit made a lot of neopixel stuff, and I found a neopixel LED strip at 0.5 meters, which is the perfect length. This will allow me to control every single LED on the strip for my LED print progress bar. I'll also order my rpi from here to save on shipping.

I found the micro-sd card and micro-usb cable on aliexpress since thats's where they will be the cheapest.

For the LED task light I already have some white LED strip laying around, I still haven't figured out how I'll power it though.

![]() Jake Hopkins 🚀

added to the journal ago

Jake Hopkins 🚀

added to the journal ago

How the heck does octoprint work?

Octoprint seems great, it gives cloud functionality to older printers or cheaper printers, and a lot of other features seen on bambu's and other new printers.

I just never understood how it works, but now I do! it just sends the commands to the usb port on the printer, like how the SD card works. Also it's really cheap, and can be set up for like 25 dollars!

![]() Jake Hopkins 🚀

started Ender 3 revamp ago

Jake Hopkins 🚀

started Ender 3 revamp ago

11/28/2025 10 AM - How the heck does octoprint work?

Octoprint seems great, it gives cloud functionality to older printers or cheaper printers, and a lot of other features seen on bambu's and other new printers.

I just never understood how it works, but now I do! it just sends the commands to the usb port on the printer, like how the SD card works. Also it's really cheap, and can be set up for like 25 dollars!

11/28/2025 4 PM - Sourced the parts

The next thing I did was source the BOM. I knew that adafruit made a lot of neopixel stuff, and I found a neopixel LED strip at 0.5 meters, which is the perfect length. This will allow me to control every single LED on the strip for my LED print progress bar. I'll also order my rpi from here to save on shipping.

I found the micro-sd card and micro-usb cable on aliexpress since thats's where they will be the cheapest.

For the LED task light I already have some white LED strip laying around, I still haven't figured out how I'll power it though.

11/29/2025 - drafted it out

This morning I used fusion 360 to design out everything I will 3d print, while listening to Leon Bridges. I started with the LED enclosure that includes a mounting system to the top of my printer, a slot for the neopixel LED's behind a removable 3d printed diffuser, and an alcove at the bottom for the task light LED's.(thats the image in pink)

I then designed an electronics enclosure that would house the raspberry pi, rpi camera, and wires for the LED's. This part was a little trickier because I find that as designs get more complex and larger I have a harder time working on them.

I then polished everything off with a healthy splattering of filets.

Finally I send the images to my iPad where I annotated them so that it's clearer to see whats going on. For that I just used apples basic Markdown tool in photos.

12/2/2025 - Figured out the mounting

After getting feedback from a reviewer, I realized I needed to have my 3d printer inside the design so people could figure out what was going on. Even though I had the idea perfectly clear in my head, no else did, and things that I thought were obvious aren't in retrospect. I think that it's a clearer now. Both assemblies will mount to the 3d printer using m3 hardware onto the aluminum extrusion. I will slide T-nuts into the extrusion, then put the bolts through the 3d printed part ad the T-nut, which is how my filament holder is attached, and can hold over 1 kilogram, so I think that this will be plenty strong.

Adding in the chunking ender 3 step file really slowed down Fusion, so this part took longer than expected

12/4/2025 - More explaing

People still can't seem to understand how my project works, which is fair. Maybe the stereotype about engineers being bad communicators is true:) I added 4 more angles, with more annotations from my iPad, and I'm going to explain them, so hopefully they make more sense after reading this.

Below is a zoomed out view of how it all works. there is a green piece I will 3d print that has the Rpi and camera(annotated). This will mount with m3 screws to the top extrusion of the ender 3.

Below is a zoomed in view of the LED assembly(in pink). It also mounts to the top extrusion of the ender 3. It has slots for both the addressable neopixels and the bright 24v white tasklight LED's.

Below is a zoomed in view of the electronics sub-assembly. It has the Rpi 03w, in green(annotated), and a arm to hold the camera(with m2.5 hardware). I drew in the ribbon cable because that kind of think doesn't work well in fusion, and I couldn't find a model for my camera, but I have an arrow showing where it will go(far left). This image is in gray to show the colors of the RPi, instead of the bright colors fusion generates to easily tell components apart.

Below is a zoomed out view of the electronics enclosure, showing how it fits in on a larger scale. It's a little confusing because one of the aluminum extrusions is also green, but this is NOT part of the design, and is a quirk of fusion. It has the same features metnioned above- the RPi, camera cable and spot for the camera. You can see that it mounts to the blue bar, which is the top of the Ender 3 gantry, and is also where the LED assembly will mount(Both will m2.5 hardware).

12/7/2025 - Explaining the features

Features:

-An LED task light!

The corner of my room that my ender 3 lives in, and past 4:30 pm(when I normally do my printing)it is hard to see anything thats going on, which makes it very hard to see print quality or errors, feed filament etc.

The LED task light uses some standard 24v white LED's that I have extras of from a past project. They will be powered by a 24v plug in power supply and go in a slot in the bottom of my LED enclosure(Shown below). It will simply be toggles on off by a switch in the power supply.

-Print progress bar!

One of the coolest features of Bambu Lab's new flagship printer, the H2d, is the LED progress bar on the side, which is way more convenient than looking at the tiny LCD display on the side of my printer. Mine will use 0.5 meter addressable neopixel LED strip cut down to length, that will be controlled via the Raspberry pi, using the octoprint API to determine how far along the print is done. The neopixel strip will be ordered from adafruit for $12.5( See BOM). The LED's will be masked by a 3d printed diffuser at 0% infill so that you can't see the individual LED's.

In the image above, this will go in the highlighted area labeled "neopixels will go here".

-Octopint!

Octoprint is awesome opensource software that runs on a raspberry pi and allows you to control any 3d printer remotely. It communicates to the 3d printer via the micro-usb port, so that you dont have to go into the guts of the printer, and it allows you to start and monitor prints from you computer, phone, or crappy school chromebook. All you need for it is a raspberry pi, cable, and sd card(See BOM). This will go in the picture below, which has the Raspberry pi modled into it's enclosure

.

-Camera for time elapses and print failure detection

Using the camera module 2 I already have from raspberry pi, I can uses octoprint to automatically take timealapses that have the toolhead home to the same spot each time, allowing for the fancy timealapses that you see on printers like the H2D. It also can locally run machine learning models that detect print failures, like the print coming loose, and send you an alert or stop the print autonomously. The camera will go into it's pictured slot in the pictured above, with a CSI ribbon cable connected to the raspberry pi. Like a said I chose this camera because I already have it on hand, and don't have to buy it.

P.S. This is my submission for Prototype, so please accept it, even if you want me to change a few minor things I will, I just really want to go to the hackathon :)

12/8/2025 - Added detail

Basically I just went back into my previous journals that were lacking detail and explained in more depth my design choices and how specific key parts will work. If I had to guess I'd say I added about 400-500 characters, not including images.

12/9/2025 - Found a new power supply

The current power supply for the raspberyr pi was to espesnisve at 7 dollars, so I found a replacement on aliexpress for 99 cents. Hoepfully it doesn't burn my house down💀

2/1/2026 - Set up octopi!

When I opened up the rpi imager, it said there was a new update, so I went ahead and got the new version of that, and I really like the fresh UI. It took about 15 minutes to write the OS, and this was mainly limited by the slow read write speed of the sd card(15 mbs). I used the octopi image preset in the rpi imager, which is just pi os with octo pi installed.

As soon as I ssh'd into the pi it gave instruction for the website for octoprint(ran locally on the pi). I went through the set up wizard and used the dimensions and heater limits for my ender 3 v2 neo. I was worried about something failing, which I don't know why, because octoprint is just as safe as sd card printing. Turns out you can't use the pi during prints though(learned that the hard way).

I really like the octoprint UI, but I'm defiantly going to tryout some plugins to for dark mode.

2/6/2026 - Wrote software

A key part of my project is the neopixels lights, which can be controlled with an amazing amount of control. I used the adabfruit blinks library, and followed the official Adafruit tutorial to get the basics of the library. I then got an API key from my pi's octoprint, and connected the ip address of the pi for the script to listen to the print status.

The code is fairly simple. When printing, it turns on the task light, and the progress bar with the print progress. When idle it lights up the task light, and pulses the progress bar green. When a print is finished the progress bar is solid green. If there is an error, it flashes the lights red. Also between 10pm and 7am I'm asleep, so it turns off the lights during those times. Hackatime tracked an hour and 2 minutes.

2/8/2026 - Octopi VPN

Because octopi runs locally on a raspberry pi, its UI is only LAN accessible. This was to large of a compromise for me, because I want to be able to monitor and start prints from anywhere. There are a lot of plugins to forward your ocotprint website through your router so that it can be assessable anywhere, but they all come with a scary amount of warnings telling of the dangers of hackers.

From what I could tell, the safest option is a locally ran vpn. When you connect to it, you are essentially on your home network, allowing you to connect to LAN devices. The easiest option to do this is with PiVPN. I am running this on my pi 5 that is always on, since it's quite a but faster than the octoprint pi 0 and won't be competing with ocotprint compute this way.

Setting up PiVPN over the CLI was fairly straightforward, although there was a lot of vocab I didn't know. I then set up port forwarding on my router, which was tricky because of the ridiculous amount of menu nesting I the app. Finally I downloaded wireguard on my Mac and imported the config file from my pi. Here is what the UI looks like.

Because the pi isn't connected over ethernet, the speeds aren't great, about 15mbs. Because it's so slow I don't leave it on all the time, but for connecting to octoprint and getting past my schools wifi bans it gets the jobs done, and I've even accidnatly joined zoom meetings on it and it handles it's self until alright

2/9/2026 - Revised the CAD

Last night I printed out my parts, and realized that it could be a lot more streamlined of a design. I updated the design so that all the components are in one solid part, instead of having a separate enclosure for the pi. I also changed it so that the pi bolts onto the part instead of just floating in a box. I also realized my tolerances were way too tight for the LED strip, so I added an extra 1mm of padding around the cutout.

I'll print this version out tonight, and hopefully everything will work well!

2/13/2026 - Soldering and pre assembly

This took so, so much longer than I expected, but I'm starting to realize that even simple soldering and assembly takes a long time. Before I had soldered the leads of the LED strip to jumper cables so that I could easily test them with my raspberry pi, but this didn't work well with the final iteration of my design (which I printed out last night).

I realized that it made more sense to cut the strip, and use separate section for both the status indicator and the task light. I was sacred to cut the LED's, even though the strip shows you where to cut it. Cutting it went fine, but I then had to cut open all my connections to add in the 3rd wire for the second strip. This way they both share gnd and 5v power. The DIN leads are separate though, and connected to GPIO 18 and 19. I then put little heat shrink tubes around the wires to that there was no bare metal showing.

I then added my heat set inserts that will keep the rpi in place. Tip, if your holding iron is super hot, you can use a leaf blower to instantly cool it down to change the tips :). The tolerances for the inserts must of been looser than normal, because 2 of them started spinning when I inserted a screw, so I had to yank them out with a combination of heat and force. The tried putting one back in, and I pushed them all in more, so hopefully they hold the super small amount of weight.!