Timeline

![]() Anirudh 🚀

added to the journal ago

Anirudh 🚀

added to the journal ago

Created the initial design and Printed a prototype

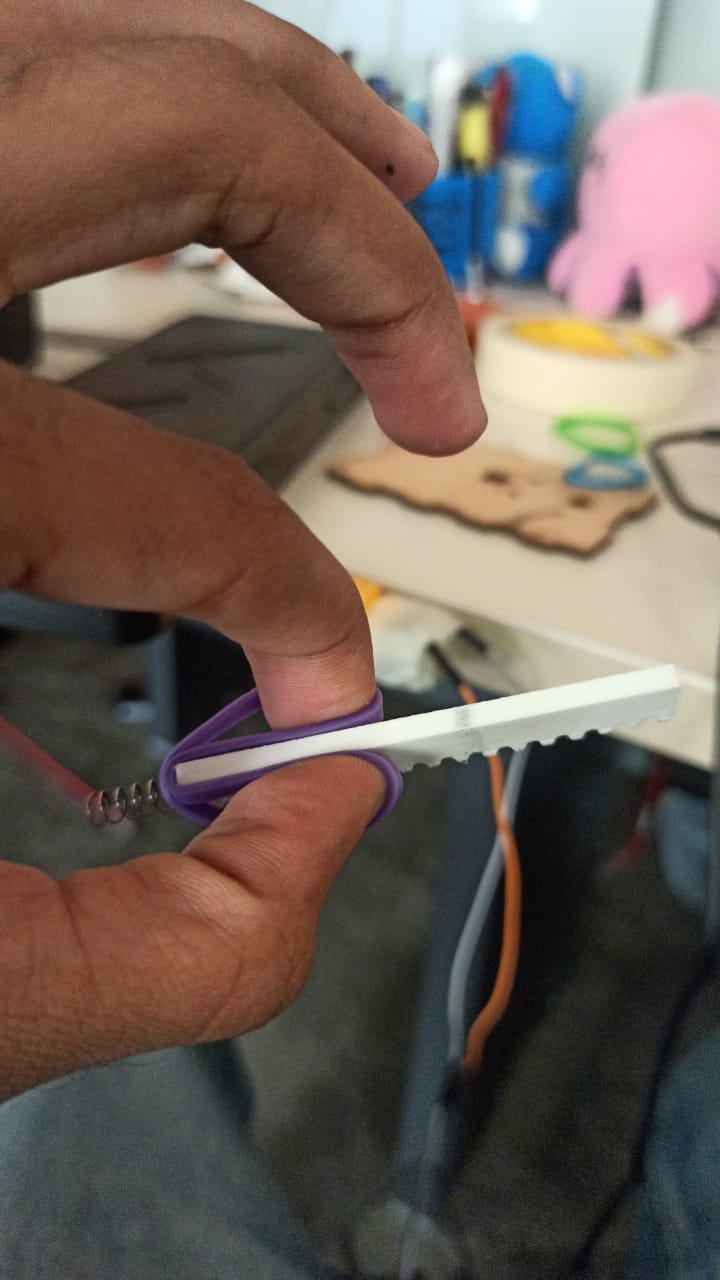

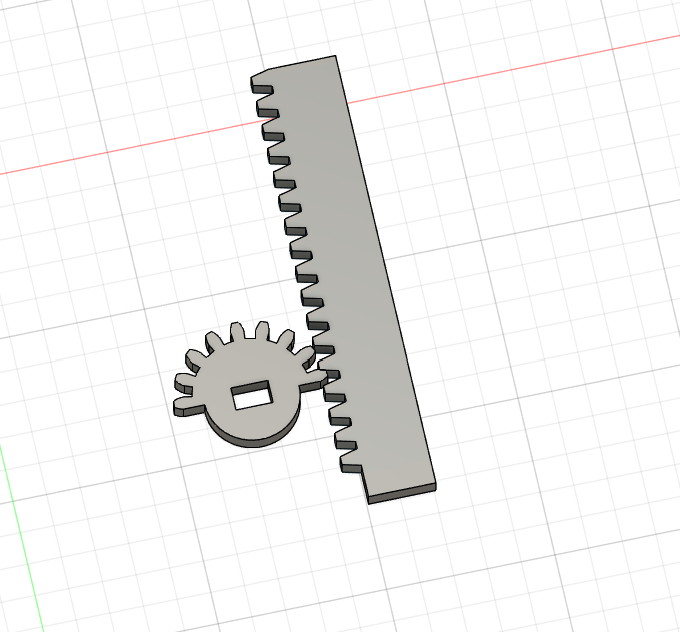

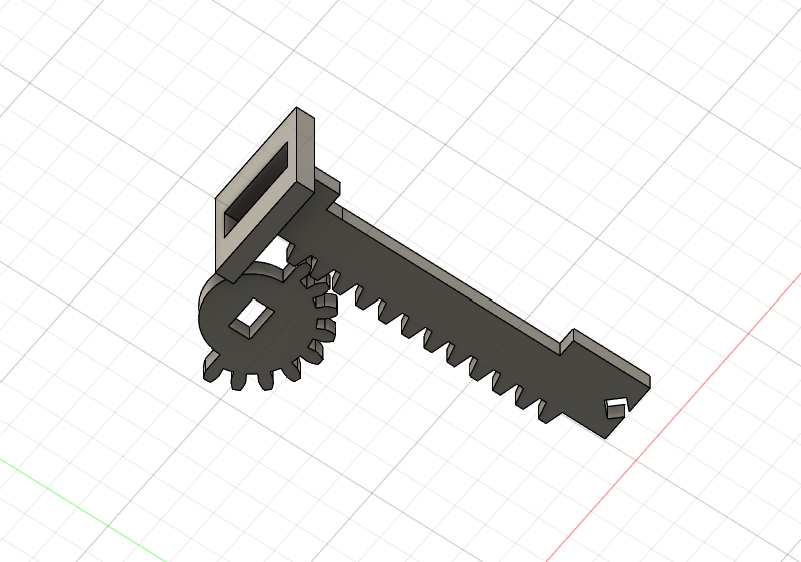

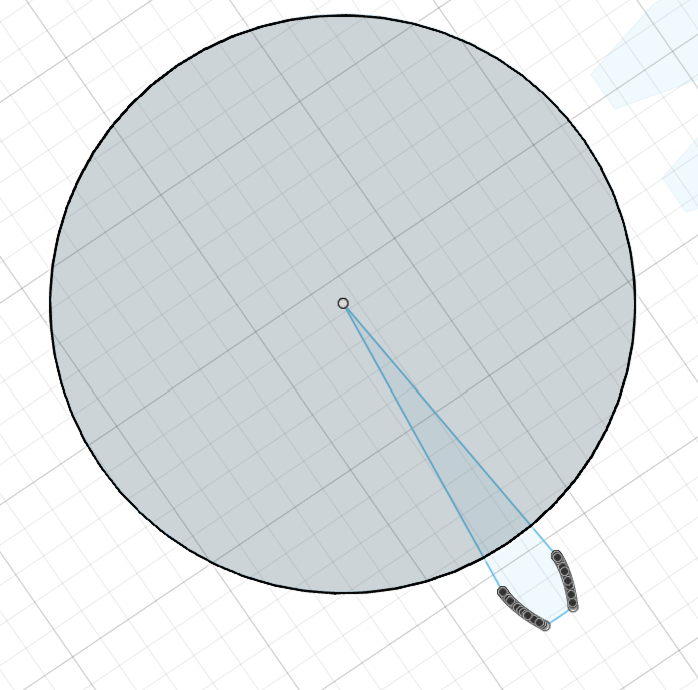

So I started working on the design and started to think for ideas of what exactly to use to make the shooting turret. Initially, I thought to use two DC motors to create like two rolling tires and just put the object and we could throw it away. That was a good idea but we had some space constraints as we need to make it a bit easy and a bit clean and use as less as possible motors and the gear system would also be hard to actually arrange. But yeah that was it so then I moved with the rubber band design and the spring designs. So both of them were kind of good designs but we needed to think of what exactly to use. Like I started to research online I found AceBot QD005 kit. They were using one DC motor only to create the whole mechanism and I saw a spring also. So I thought it was a good mechanism to start. I couldn't find any data sheet or existing project related to this turret. So I had to start from scratch. I created the prototype design on my notebook and then I started to 3D design the gear system. I decided to use half gear system. So I created the half gear and a rectangular gear which would be moved by the DC motor. I am using a DC motor with RPM of 200 so it has a really great torque. Initially I printed the mechanism on the bamboo H2D and tested out how it's working and the alignments were pretty good so I didn't have to change anything. Then after the printed part I attached a spring from a normal pen and to insert the spring I used a soldering iron and then heated the spring and melted it into the 3D printed part. Then I tested it out and it worked pretty well. Here is a video also of it working. So the main issue that I was facing that the teeths were nine teeths. So the distance it was going backward due to the motor completing one revolution was around 35 mm while our spring was only of 15 mm, the elongated spring. So there was no way that we could compress it that much and even if we use a bigger spring it would have been a problem. Then I started to explore the rubber band option as we had a lot of rubber bands and rubber band might be the key to actually create a good one because we could easily replace the rubber band and the assembly would also be very very easy. So I switched to the rubber band approach and then I started to work on the design which we will be using. I had to take some measurements for the balls that we are using. So that came out to be around 10 by 10. So I had the 18 by 18 design for the barrel itself because the FDM would take 3 mm each side so it would be around 12 mm only. Then I wanted to like then I spent a lot of time brainstorming on which exactly to use like where should be the placement of these rubber bands and how should we use one rubber band. But till now I have created the mechanism with the rubber band and have two slots and now I will be working on the barrel part and hopefully we will finish it very soon.

WhatsApp Video 2025-12-09 at 08.11.38_dded2afd

WhatsApp Video 2025-12-09 at 08.11.48_f593b145

![]() Anirudh 🚀

started Shooting Turret ago

Anirudh 🚀

started Shooting Turret ago