MAKZY

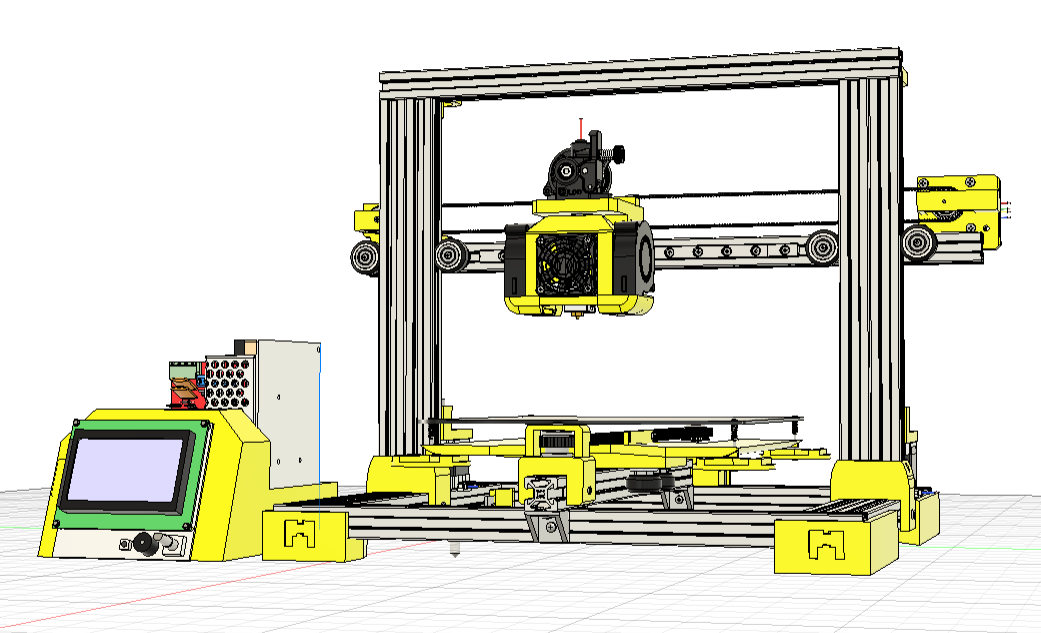

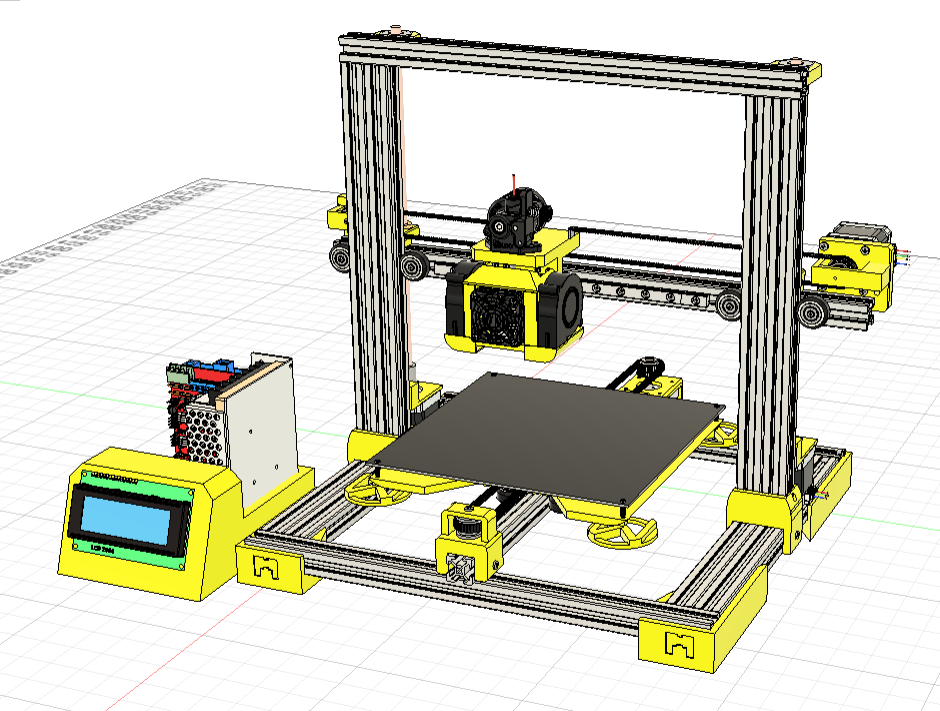

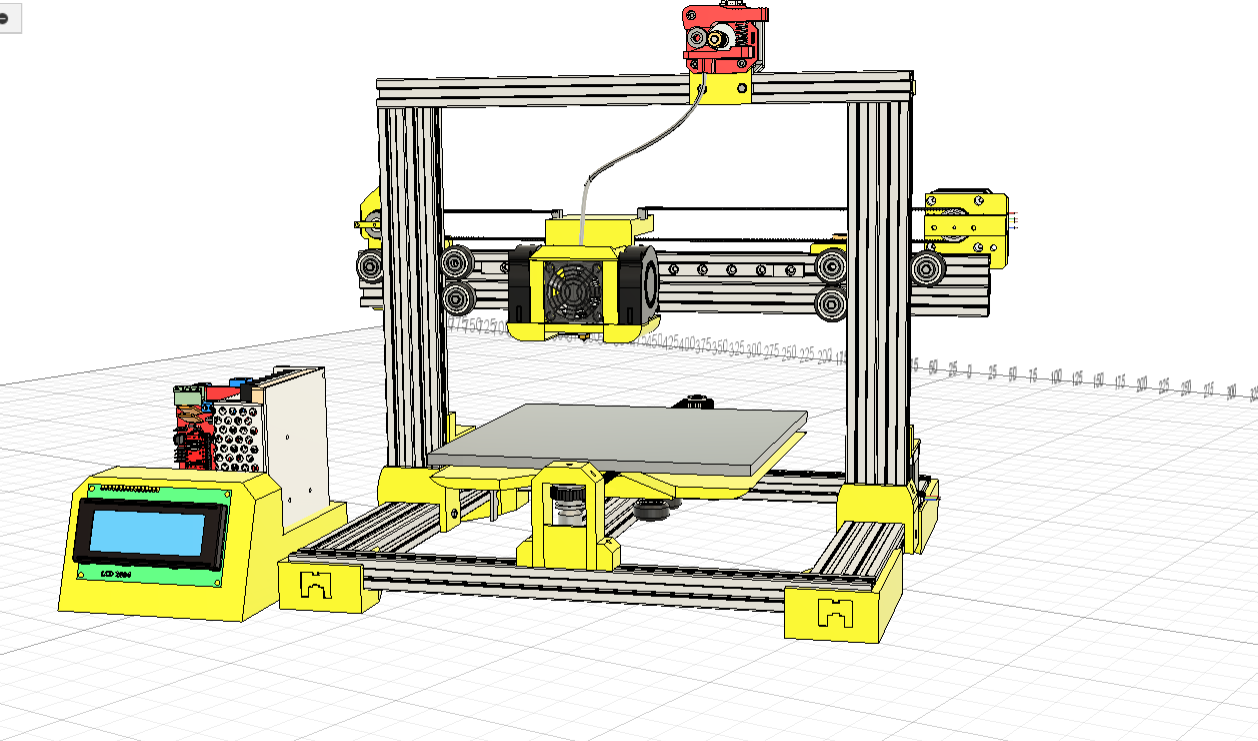

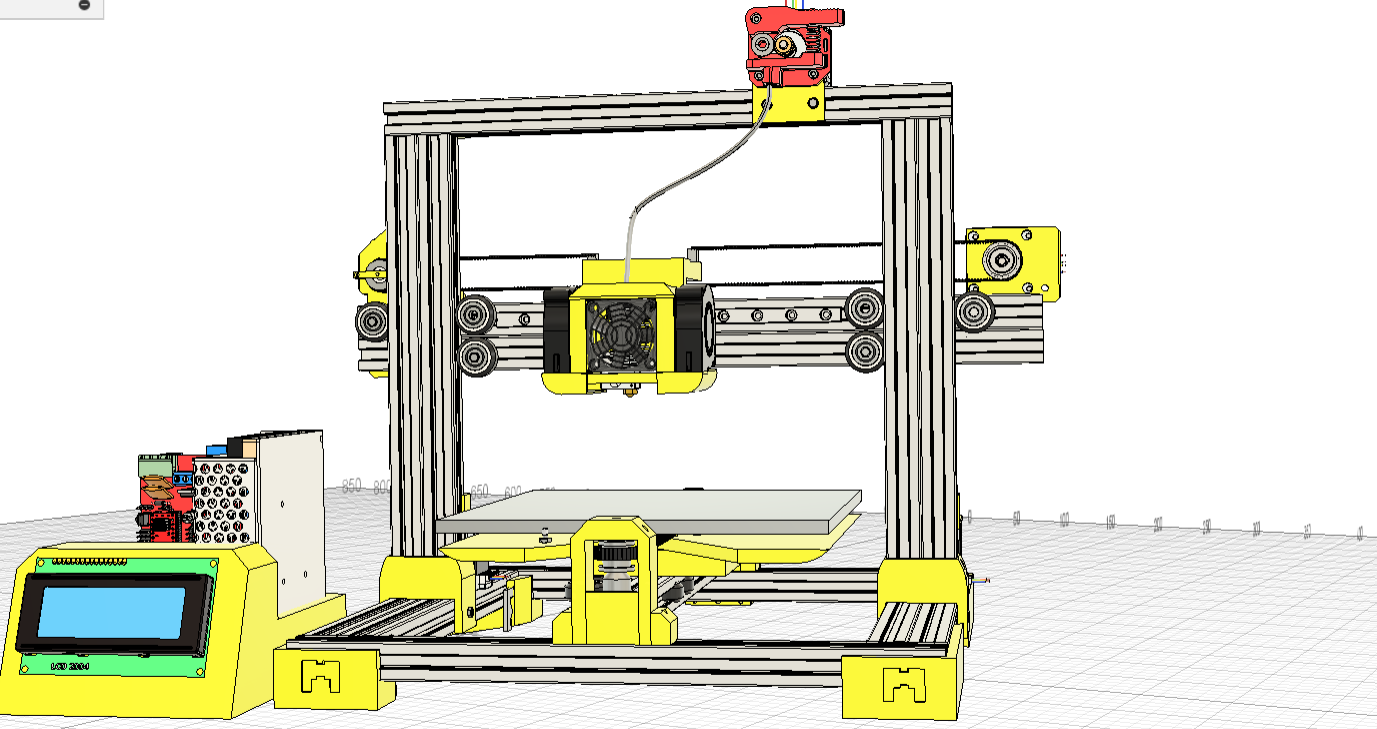

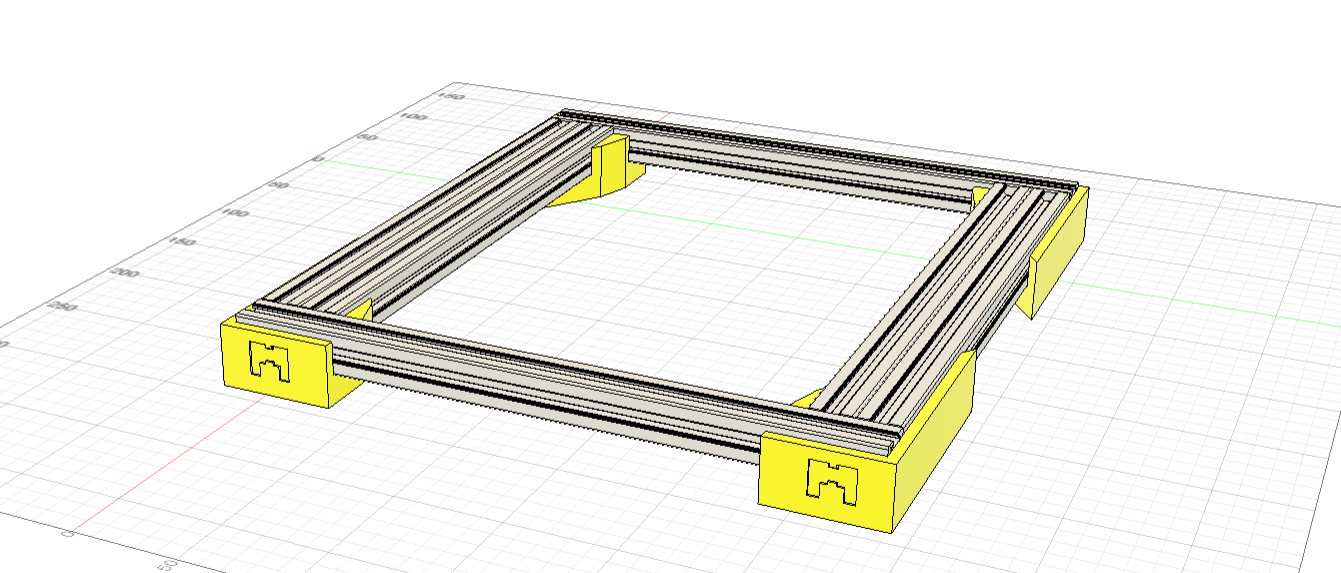

MAKZY IS BROTHER OF MY FIRST PRINTER TOYZY ,WITH IMPORVED MECHANICS AND LOOKS WILL BE USING SAME ARDUINO AND RAMPS FOR THIS AS MY BROS SHOULD HAVE SAME HEART BUT YEAH IT WILL GOOD AND BETTER THAN BEFORE

Created by

![]() Amu 🚀

Amu 🚀

Tier 1

55 views

1 follower

Timeline

![]() Tanook 🚀

rejected MAKZY ago

Tanook 🚀

rejected MAKZY ago

as per user request, user wants this project deleted from bp, thread https://hackclub.slack.com/archives/C09CMJV6V6K/p1764260432880329

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() alexren ⚡🚀

requested changes for MAKZY ago

alexren ⚡🚀

requested changes for MAKZY ago

Hey! I'm returning this project because you already have a pending 3D printer and that hasn't been built yet - if you have, update the TOYZY repo with your built printer!

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

Made the changes again

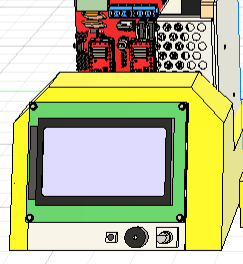

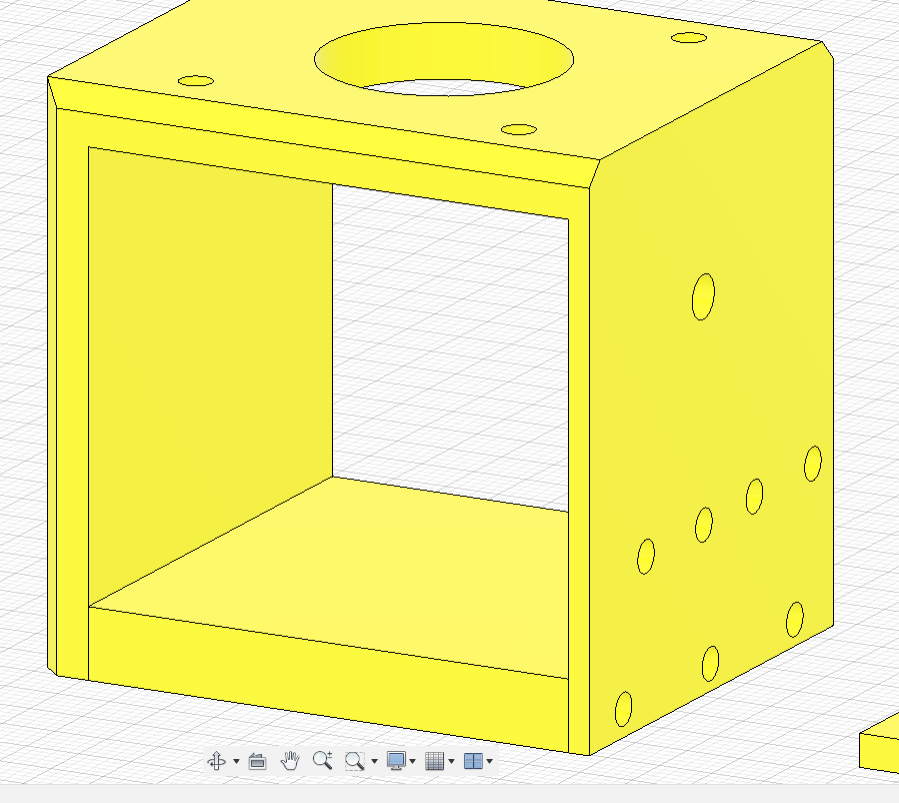

i dont know why it happens to me but the changes in the file i made was old one yeah you can check in the image also it had the old lcd screen so again made the changes int he tool box where lcd is installed so made the box broad again and then made space for wire also so that i could easly installed.png)

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

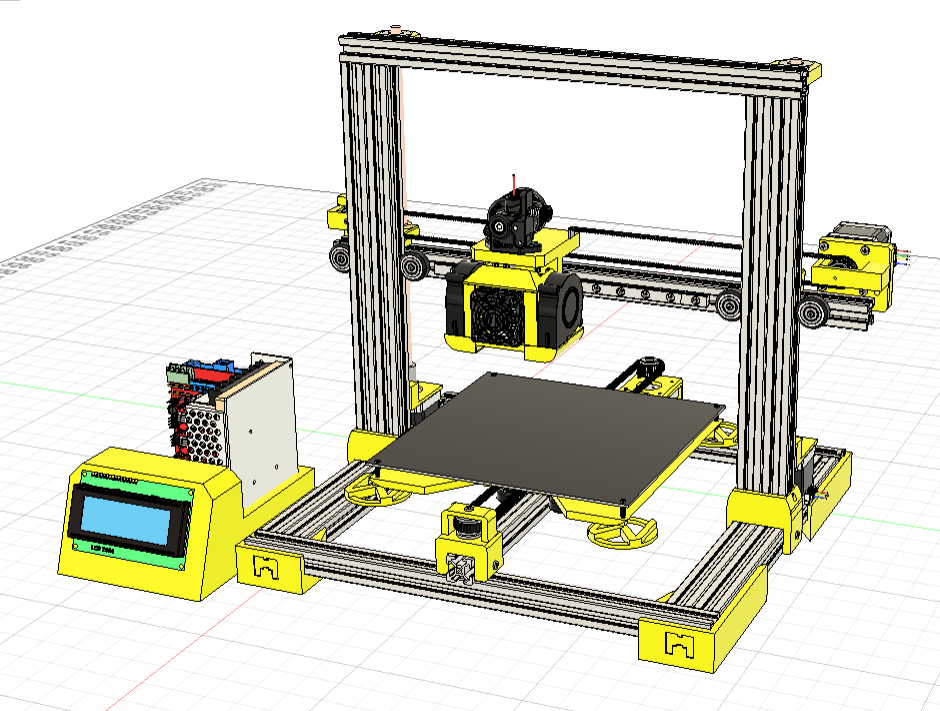

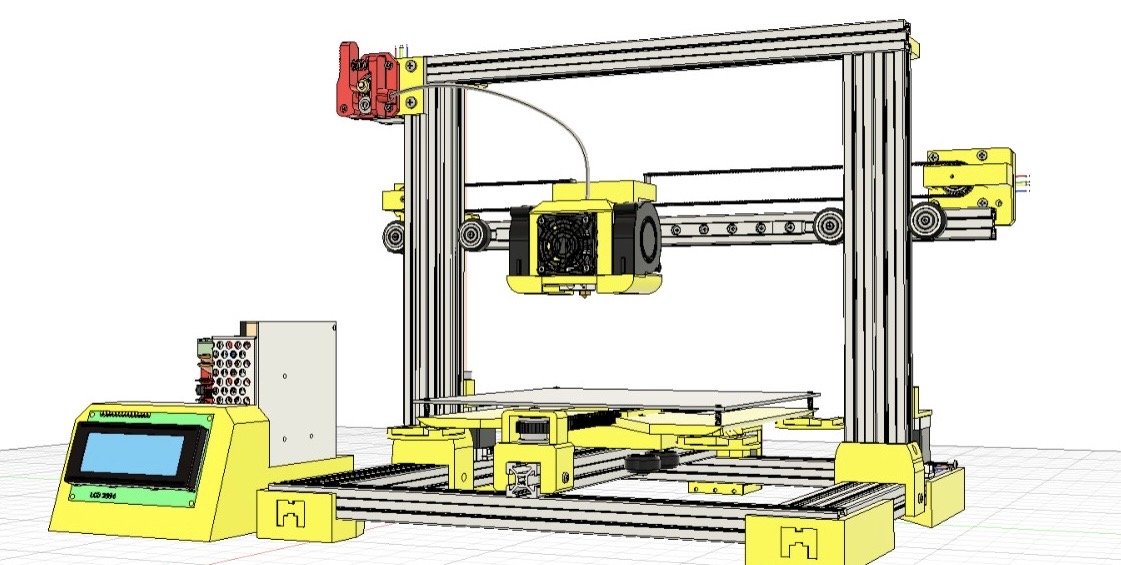

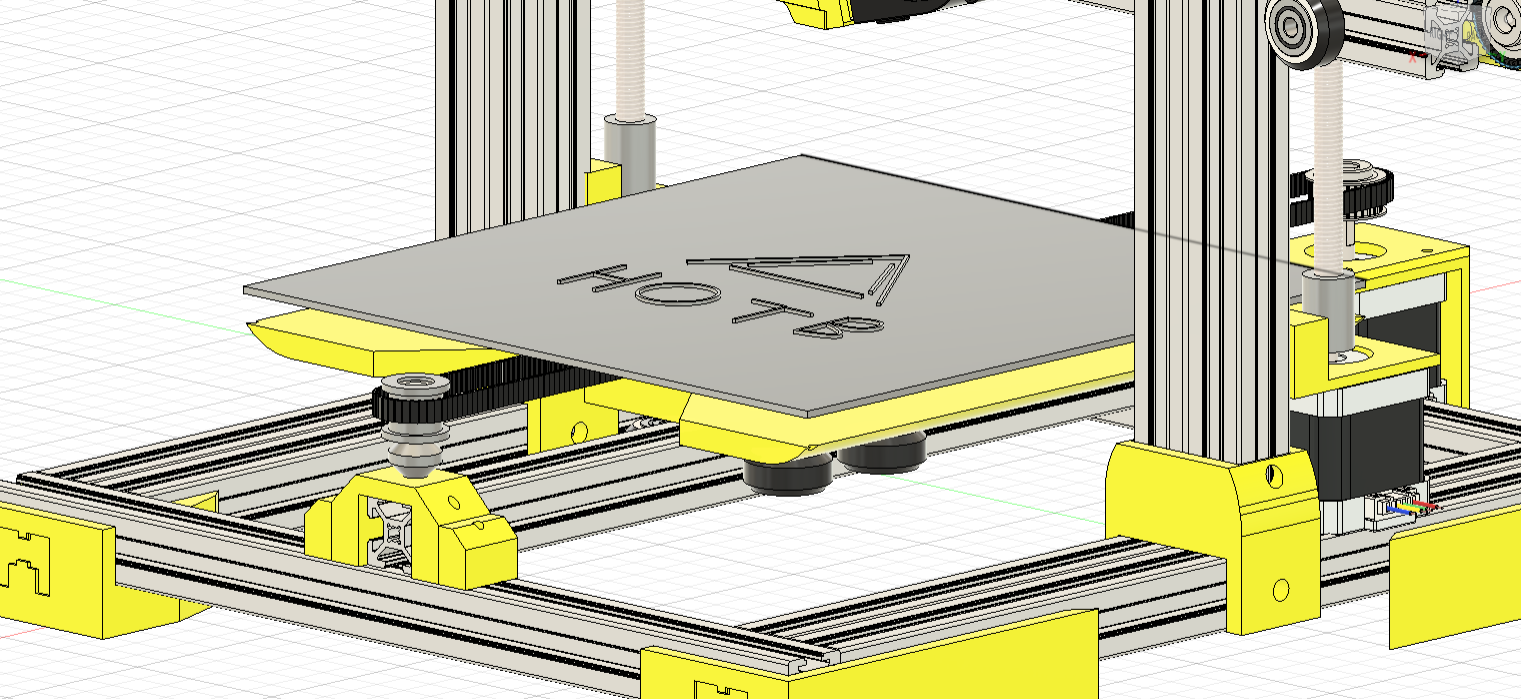

Did Some Tweeks in Cad

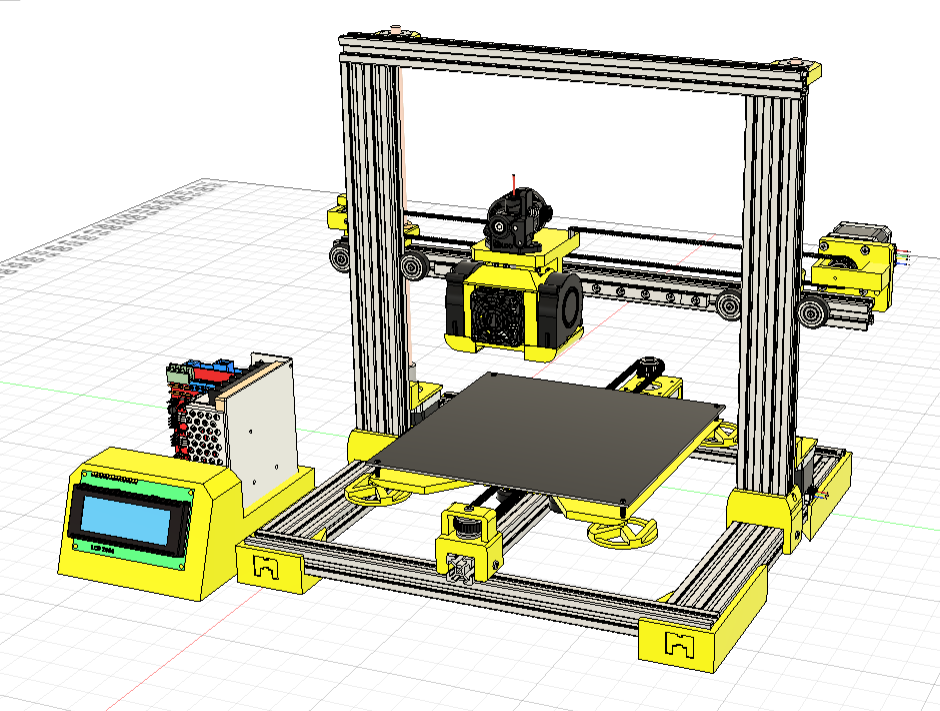

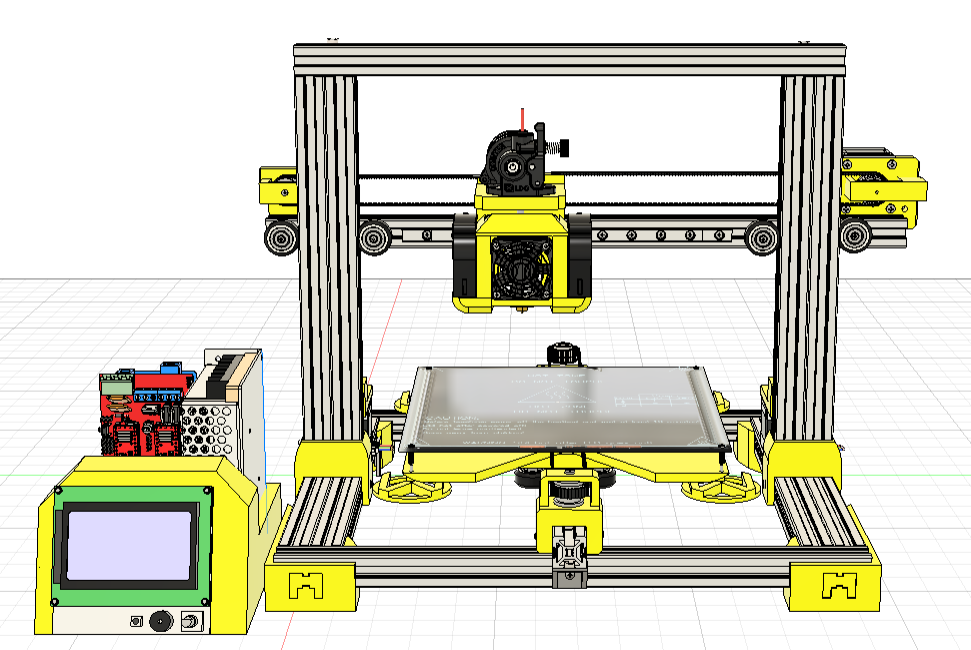

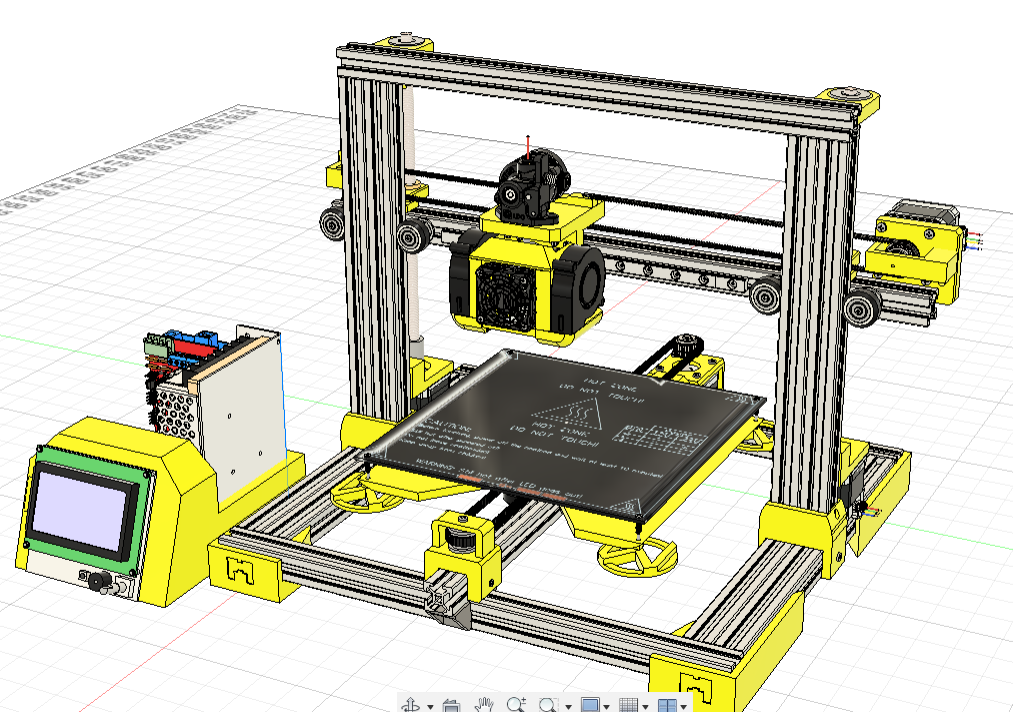

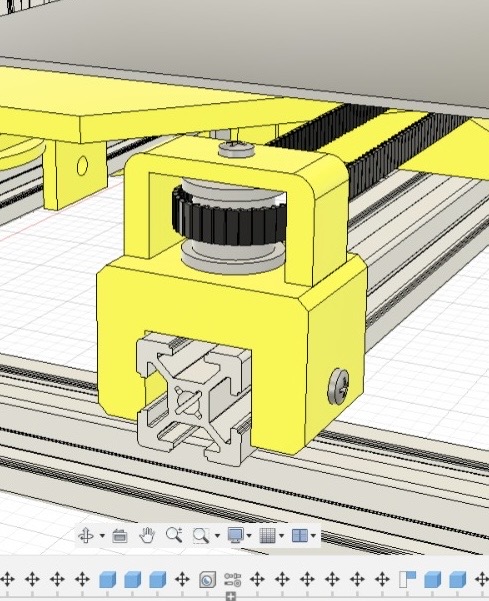

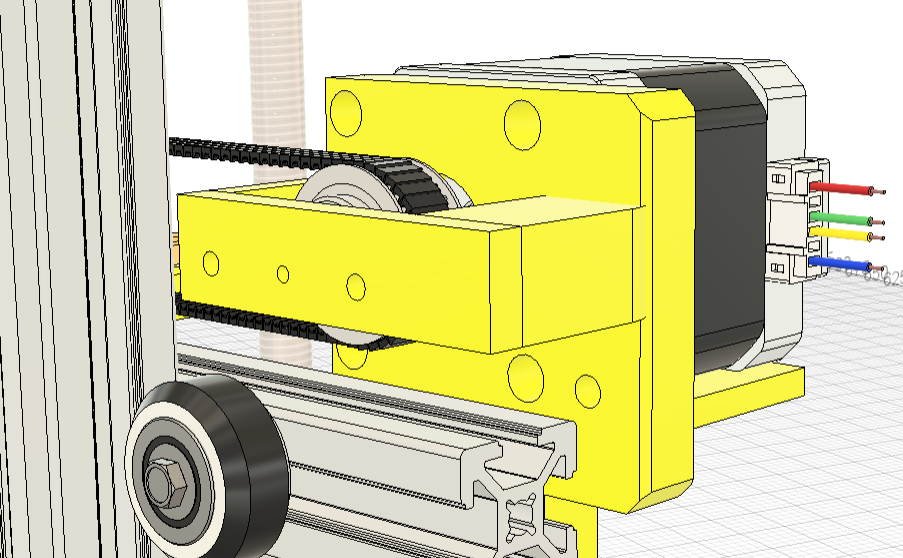

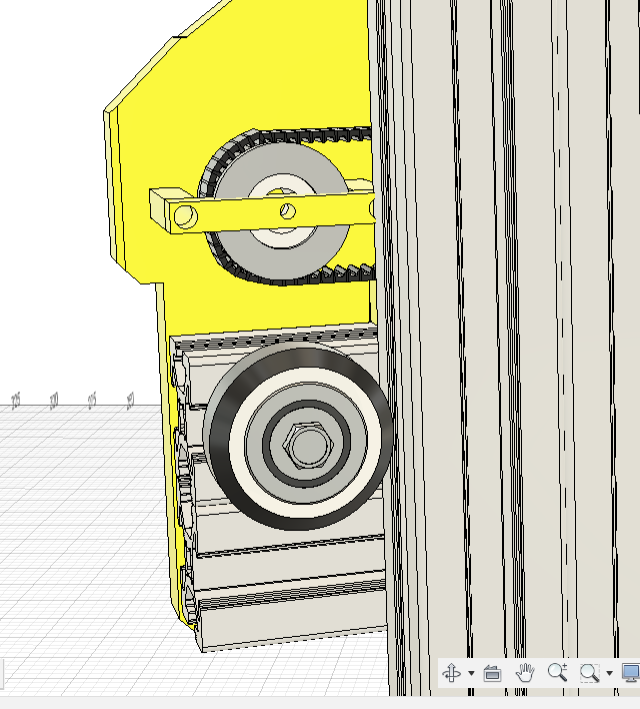

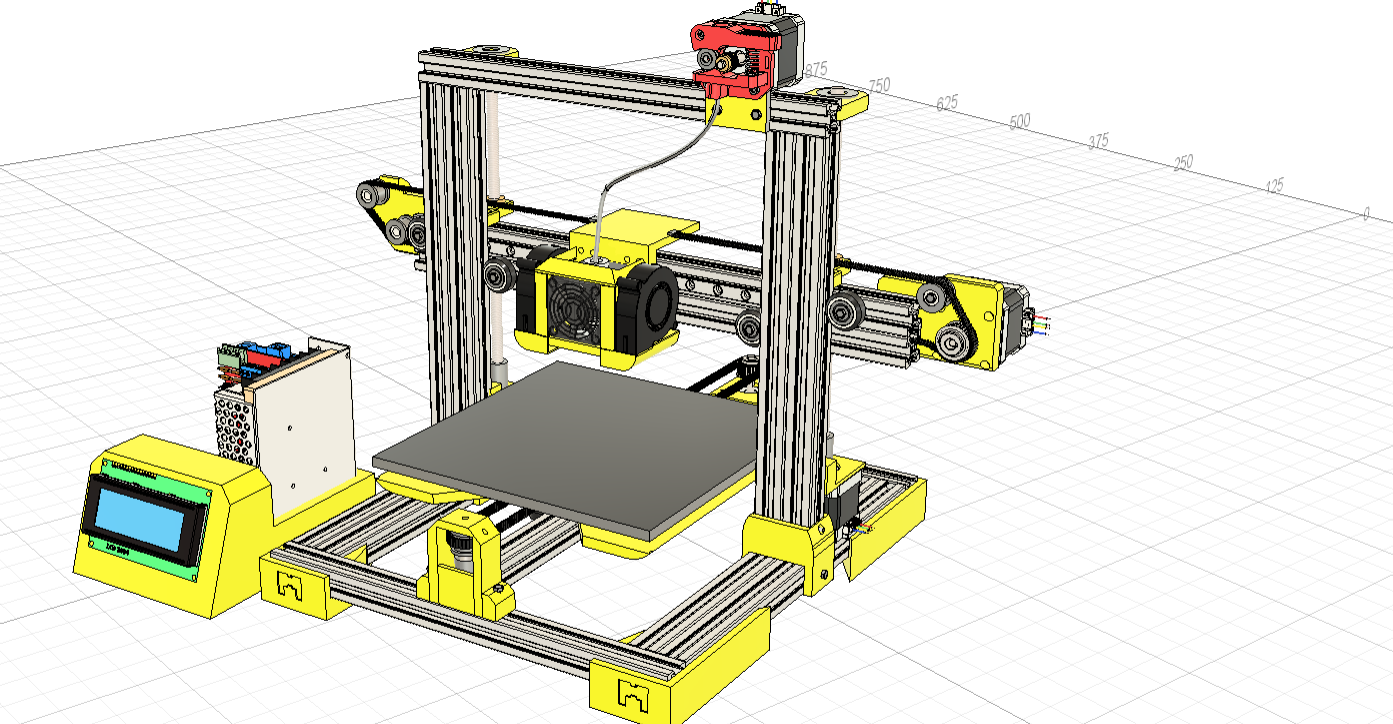

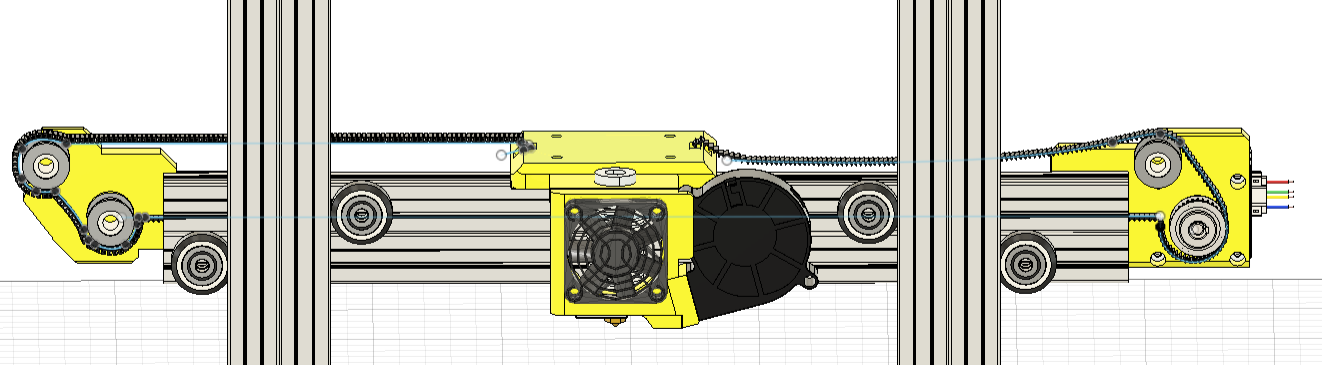

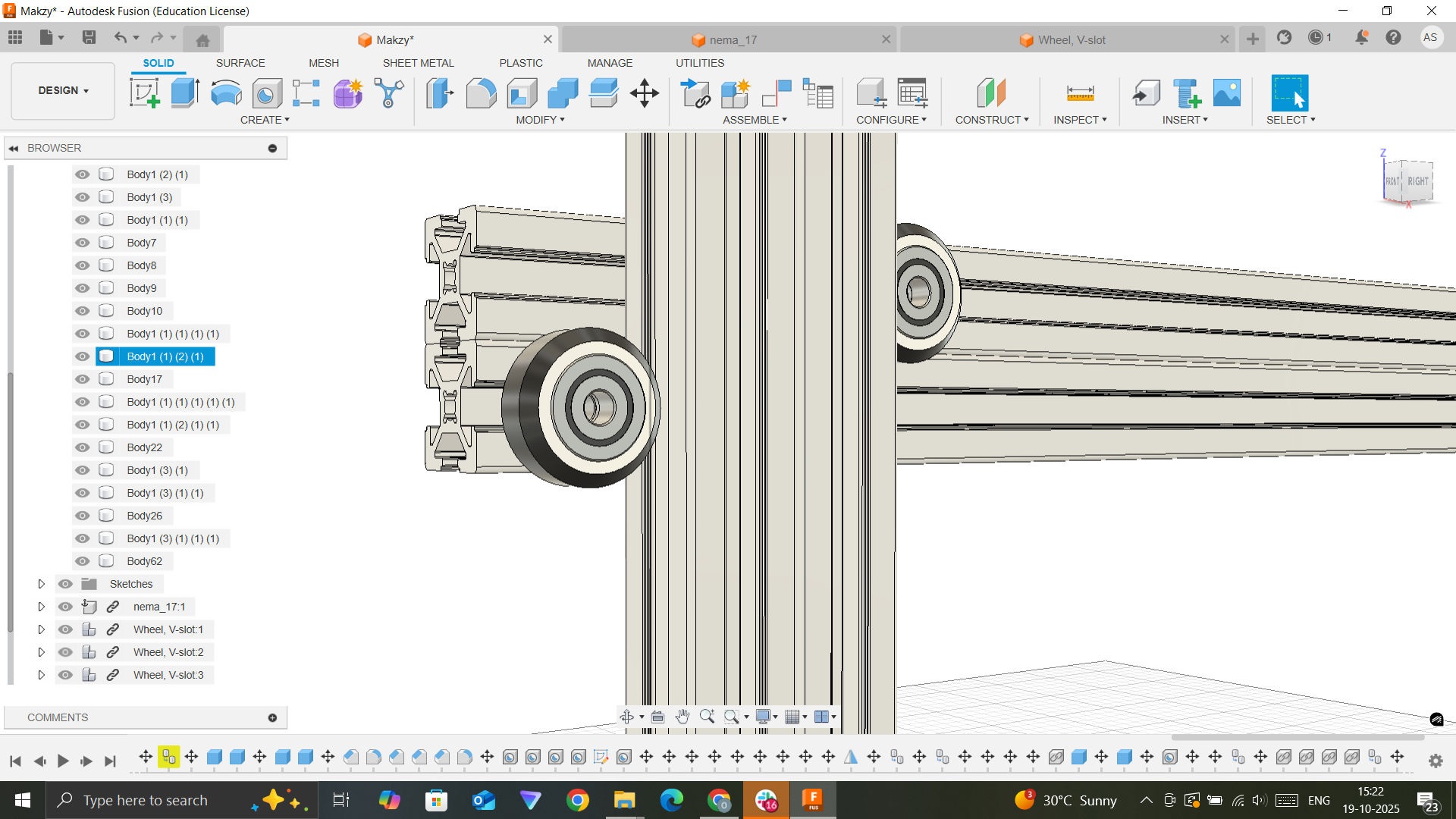

hmm i was just casually showing my friend about the cad and full model then i realised i have left some detials for the printer which was left to add so i yeah i made some chnages and did some important changes like the extunsion at the was ging inside and intersecting as i did not have the og copyof the printer so i was facing issue in making changes so i delted the aluminium profile and then readded it also some location were left where t nut and screw were not there so also added that the also the belt was also not aligned so i fixed that also , the lount for the x axis extrunsion was not also combined properly so i made the body as a whole

yeah all this took me less than a hour maybe like 45-50 min so ig i have made the model good

.png)

![]() Tanook 🚀

gave kudos to MAKZY ago

Tanook 🚀

gave kudos to MAKZY ago

User wants this project for tickets

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Jay 🚀

requested changes for MAKZY ago

Jay 🚀

requested changes for MAKZY ago

Hey, you can't buy filament as part of your grant. There is a reimbursement process. Look at the FAQ.

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Jay 🚀

requested changes for MAKZY ago

Jay 🚀

requested changes for MAKZY ago

![]() 1Mon

requested changes for MAKZY ago

1Mon

requested changes for MAKZY ago

nice printer! please show the entire cart in your screenshots! also, please fix the bom on the repo, the prices are not accurate and many of the links are broken

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Tanook 🚀

requested changes for MAKZY ago

Tanook 🚀

requested changes for MAKZY ago

I talked to u abt the LCD in DMs, and it doesn't seem to be fixed.

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

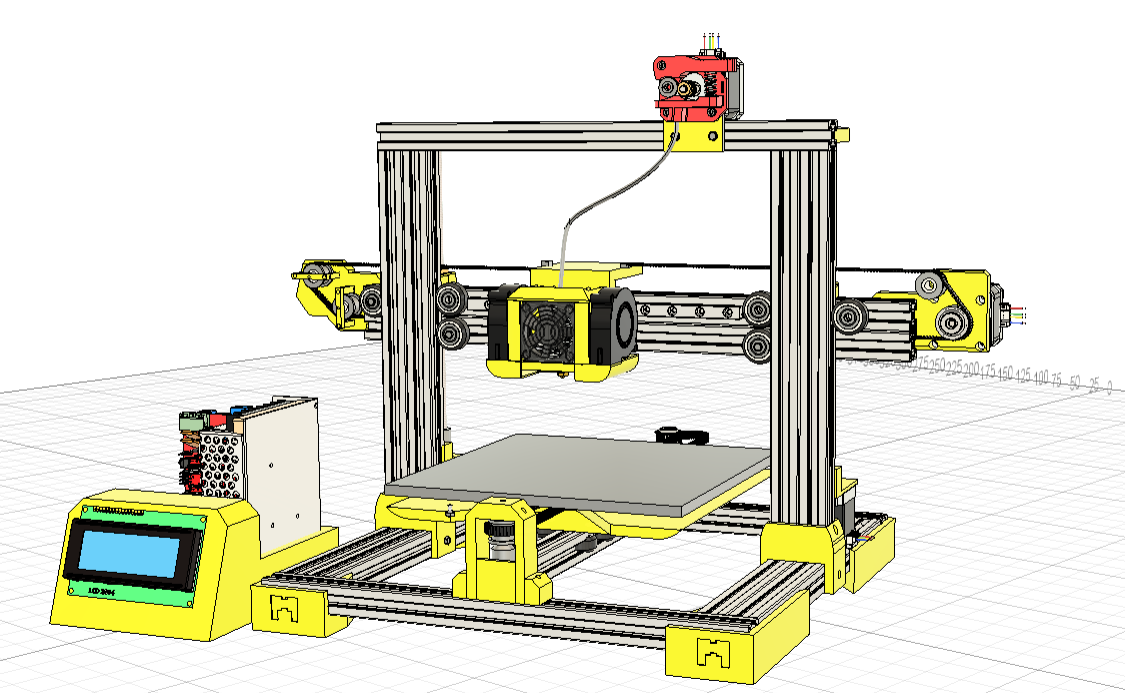

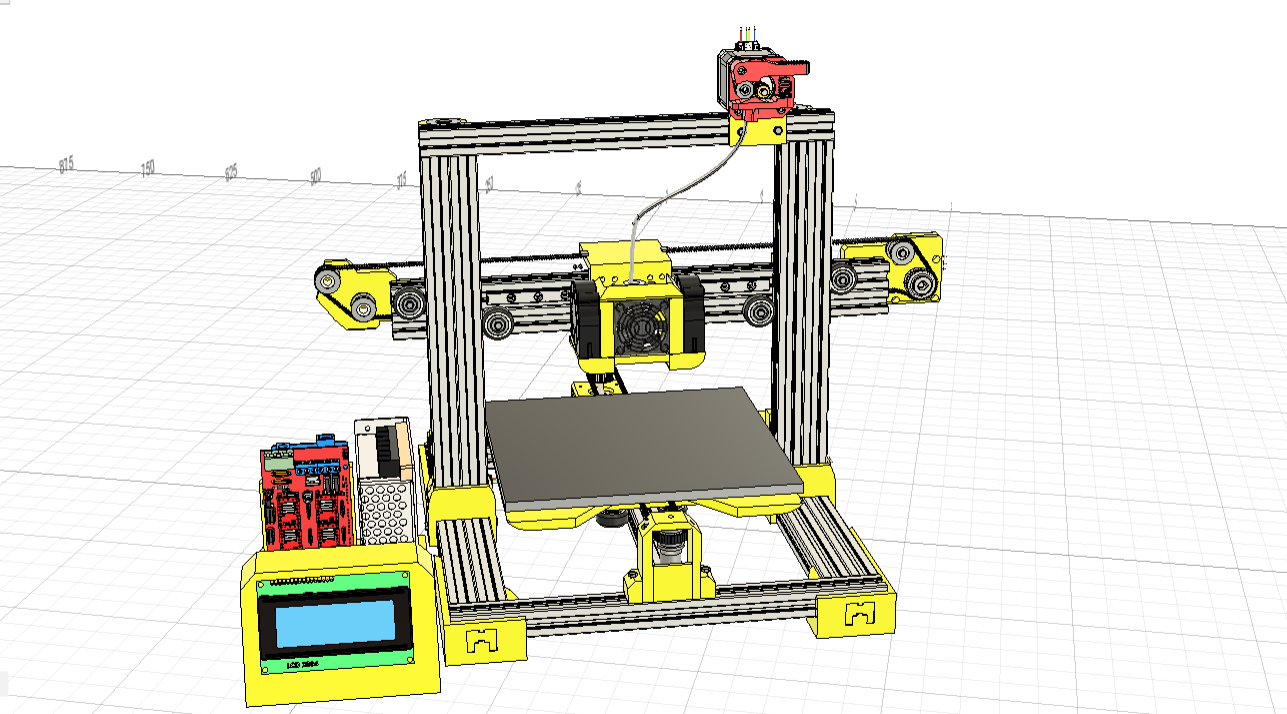

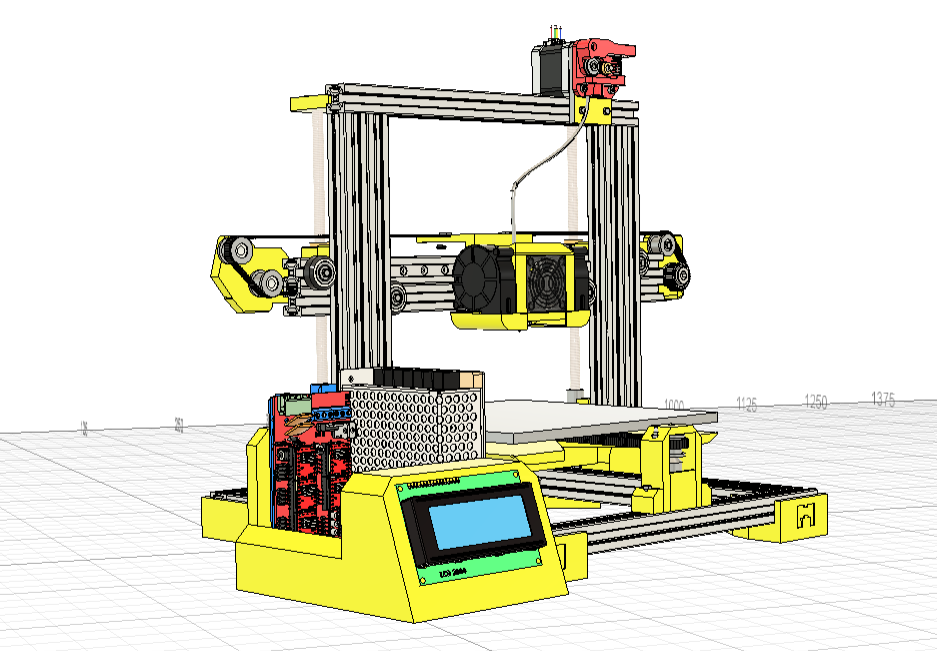

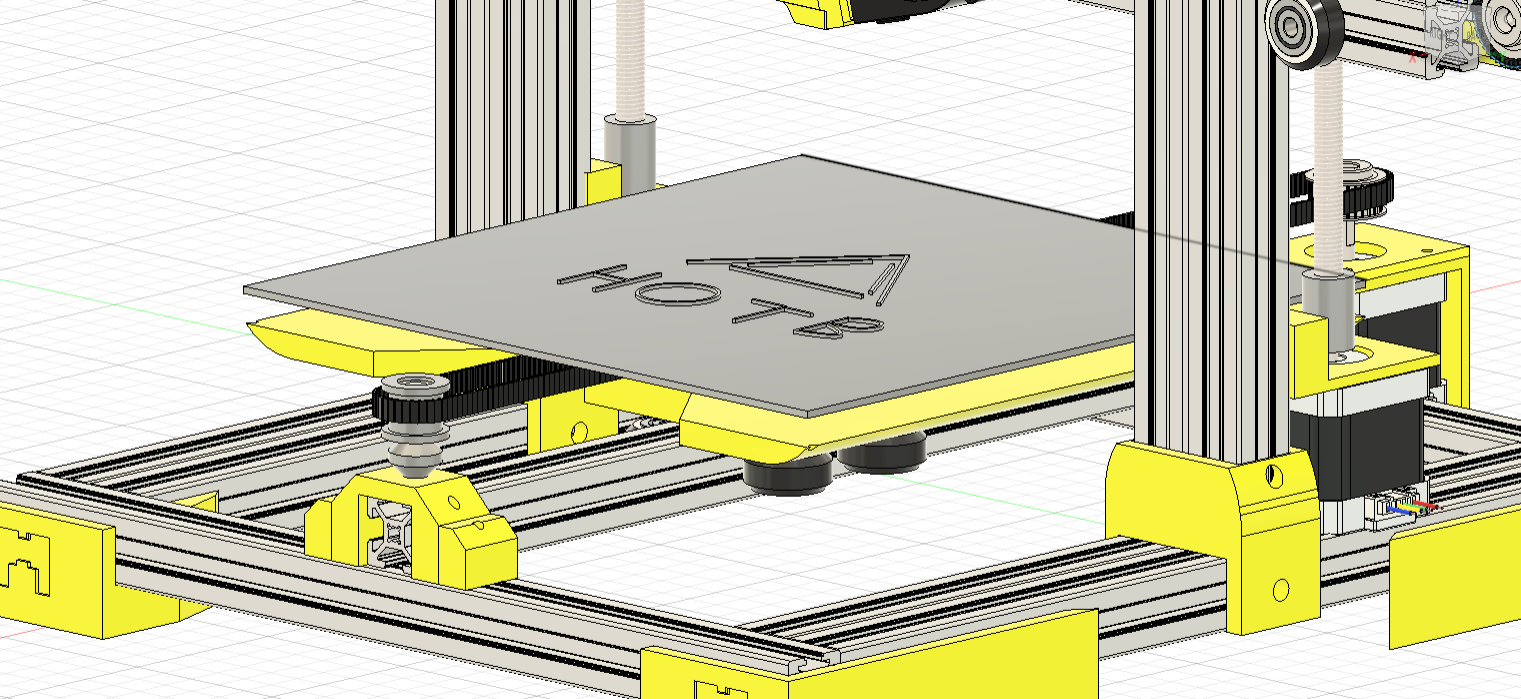

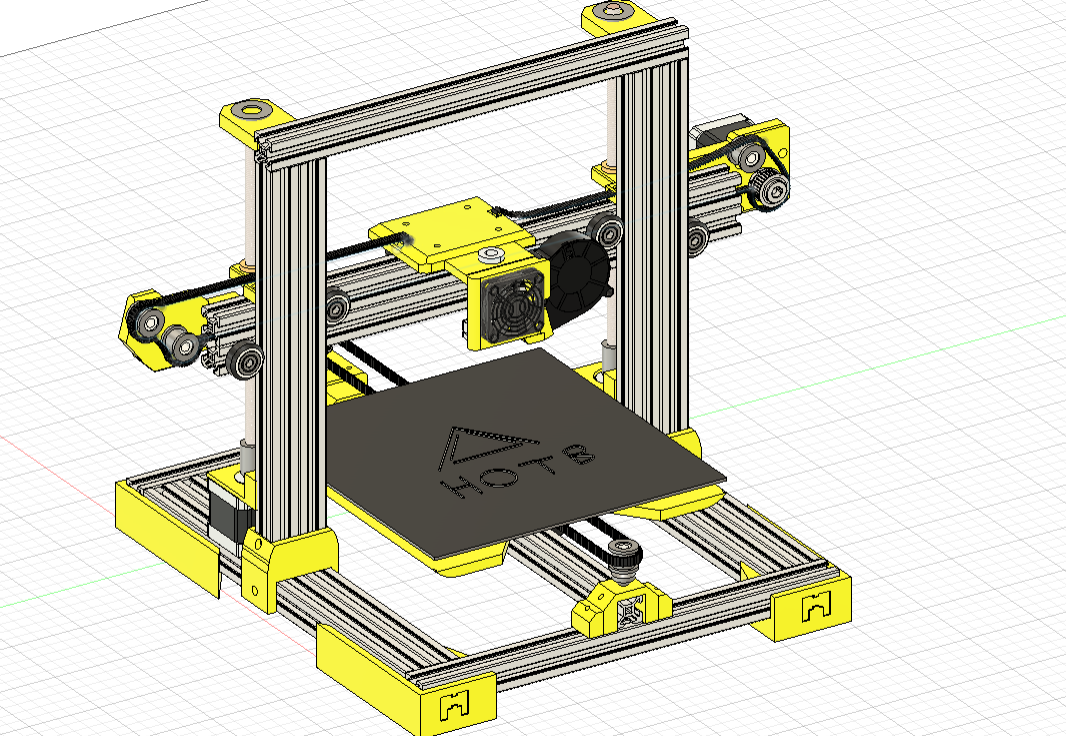

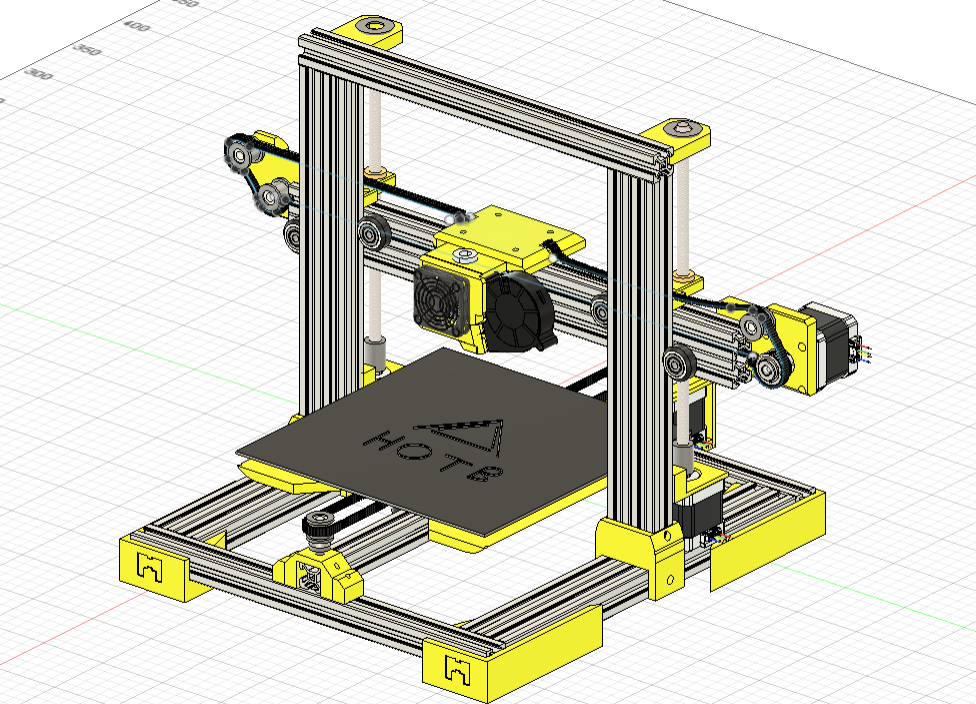

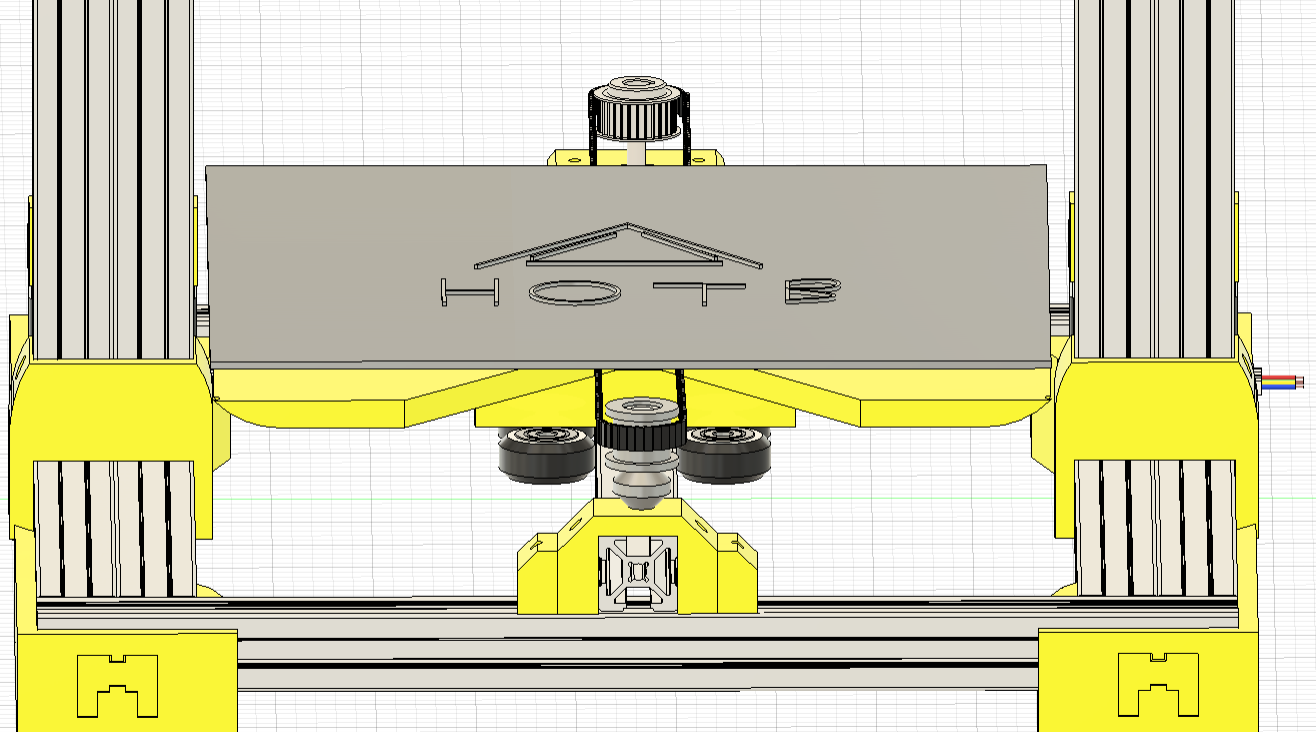

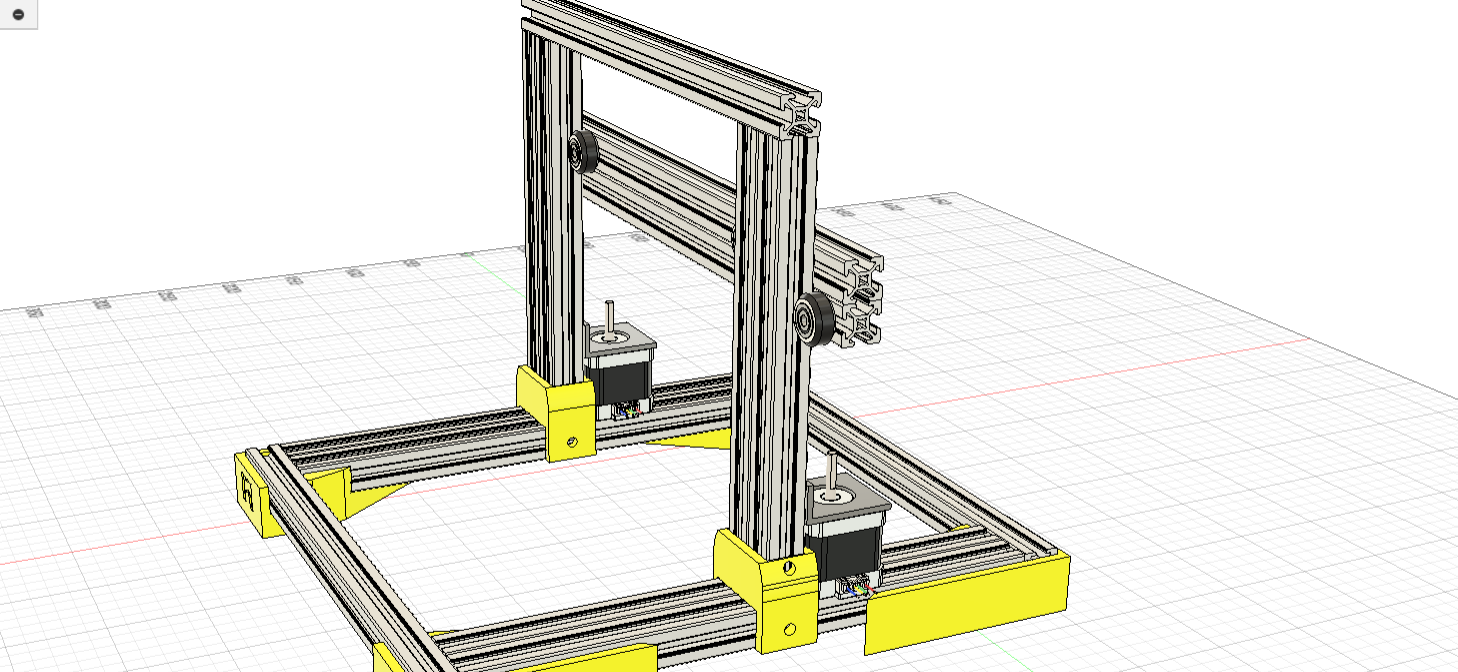

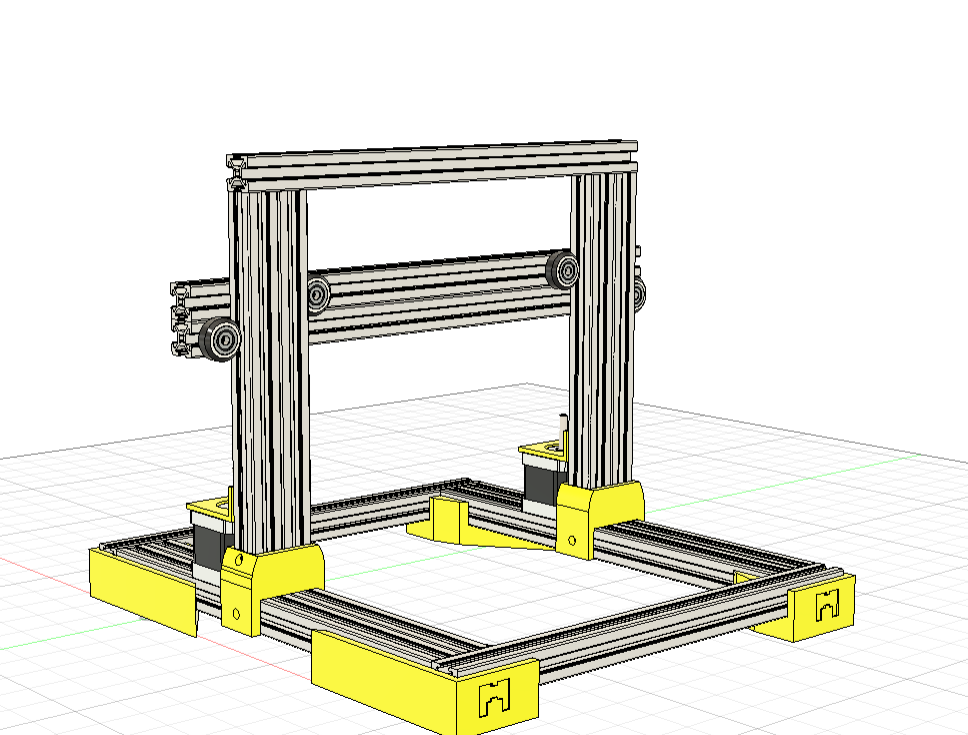

Final Looks

Here is the final look of the printer and tool head i think i have made great thing idk i cant add fake hours to the journal so made of 10 min so that i can showcase the latest images of the cad .png)

.png)

.png)

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

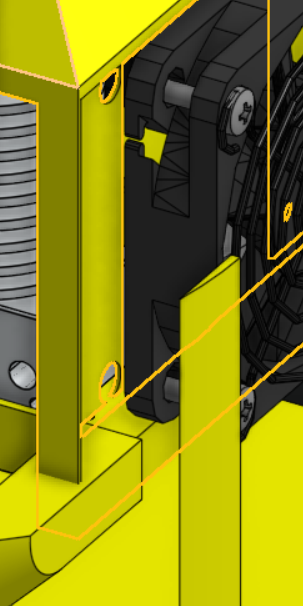

May be some last changes

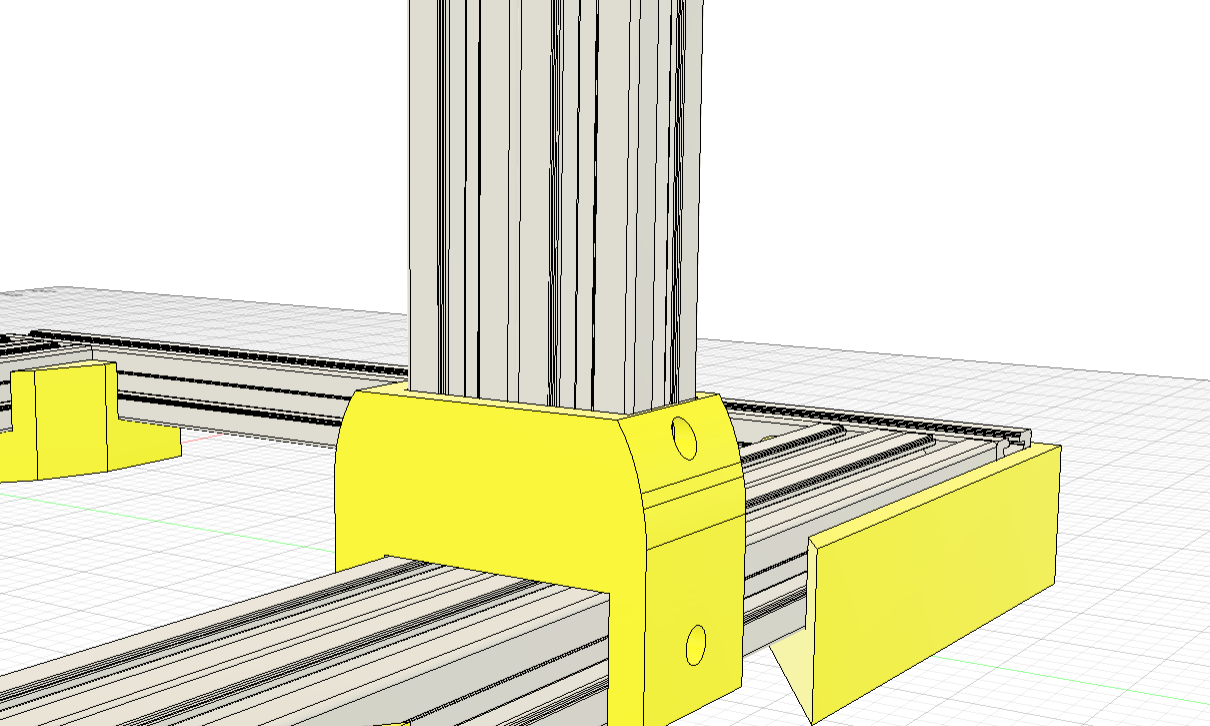

first of all i combined all the models .png)

.png)

roaming freely becz they were designed separately for accuracy do all this took me a hour

then i made a edge joint for the extrnsion to be stable .png)

also i have added t nut inside the extrunsion as suggested by tanishq change the model of diplay and also made the bed heated in cad so yeah i have add all those things to the cad which should be used in real life making

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Tanook 🚀

requested changes for MAKZY ago

Tanook 🚀

requested changes for MAKZY ago

DMed reasons, TL;DR belt tensioners dont tension, and a lot of the parts are weirdly separated

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Tanook 🚀

requested changes for MAKZY ago

Tanook 🚀

requested changes for MAKZY ago

Can u clean up ur repo to have the cad in one folder etc?

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

Journey Till Date

hmm so ig i have reached to a that part from where i can proudly say i have made a great thing is a diff thing its still pending to be made irl but i trust my guts that it will also be done

Challenges i Faced

the first challenge and a major difficulty i faced was making overall cad in laptop ,bcz the ram isnt good i tried to upgarde it to 16 gb but dont know its not optimized or what it has just slowd down my pc more anyways another thing which ig was hard for me to make the belt as it was really time taking and when i had to change the belt to a diff position it would take so long to delete and then to make it again

another thing in which i faced difficulty was making a proper functional parts so that it could not suffer any prob in future working

as i had to make a almost perfect model so it took me so long to do rnd and learn new thing along with studies but didnt stop tried and tried again to setup those idlers and duct and wheels but yeah

it was all which i can say gave a opposition in shipping this project .png)

![]() Tanook 🚀

requested changes for MAKZY ago

Tanook 🚀

requested changes for MAKZY ago

.zip doesnt open for me and plz add mor 2 ur journal

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

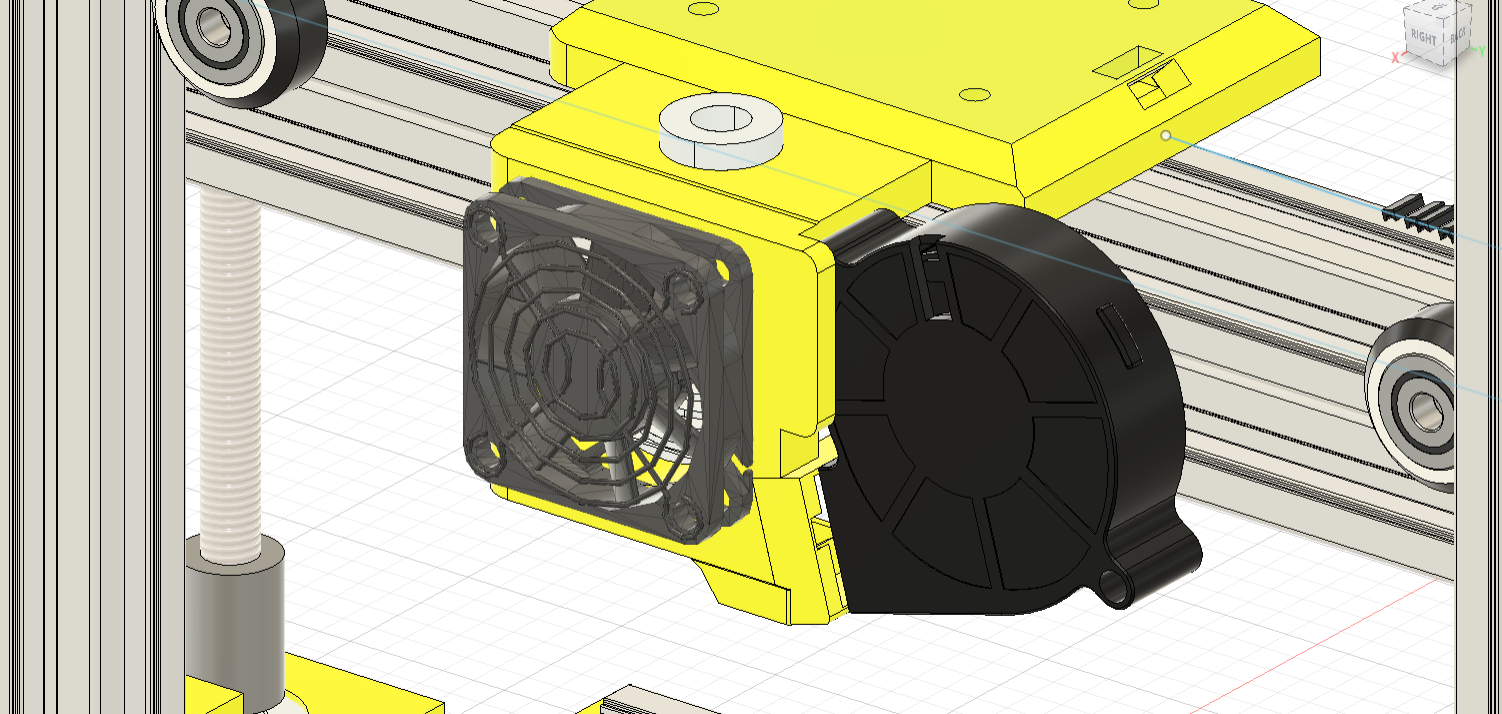

Fixed Bowden

.png)

.png)

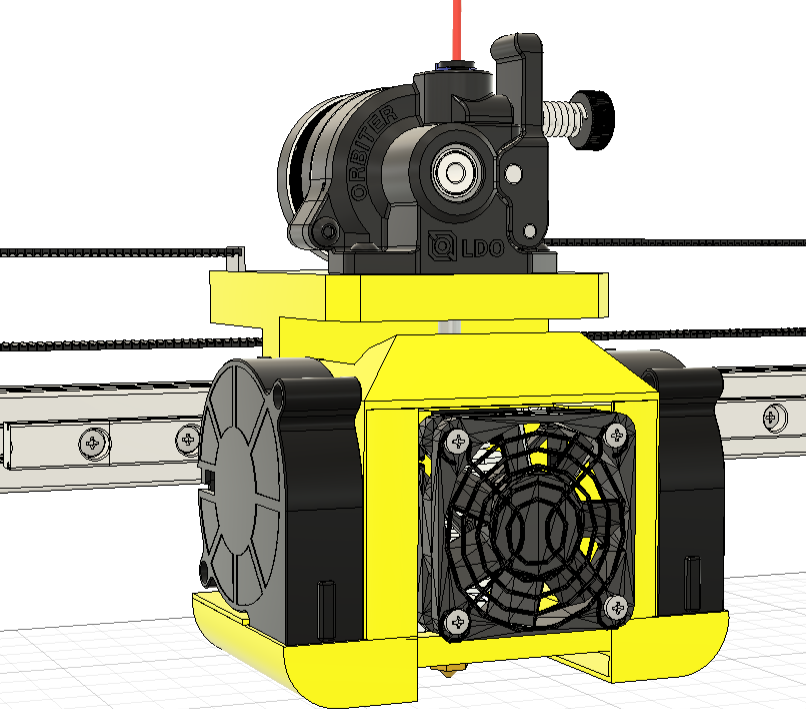

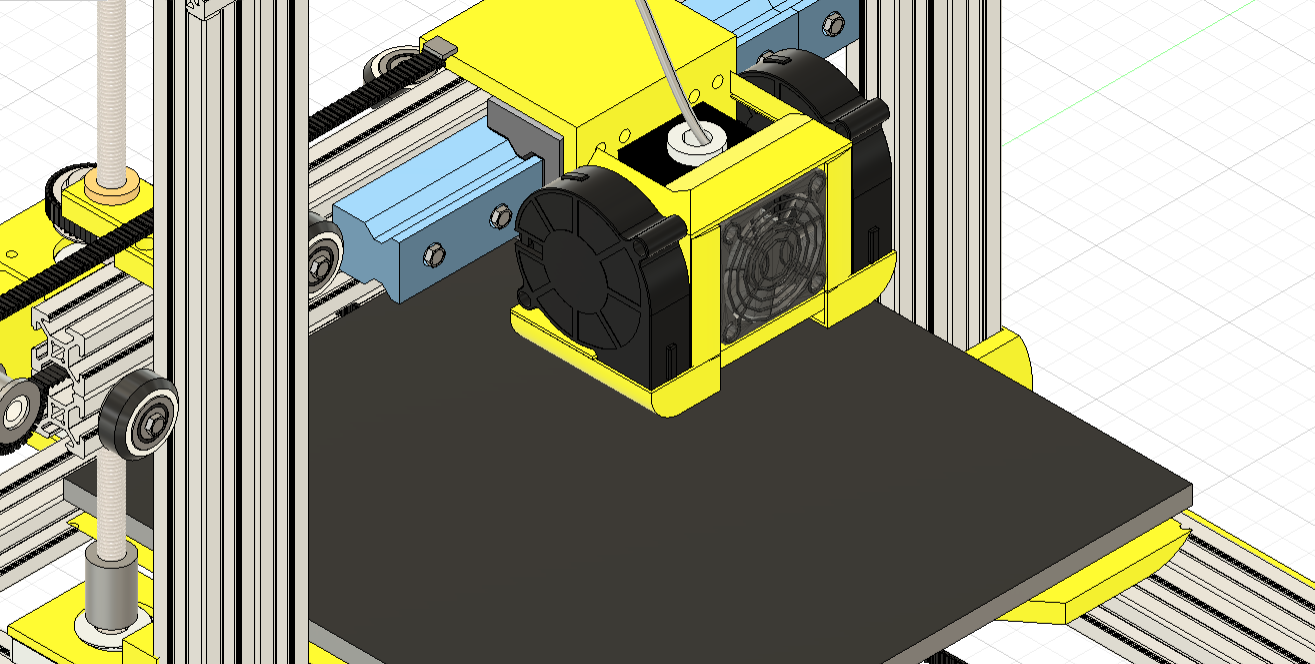

After Another review i decided to go with direct drive instead of bowden so instead of using a old fashion extruder i decided to go with better one so after some searching about extruders i found a clone of orbiter v2 extruder with almost same functionality

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

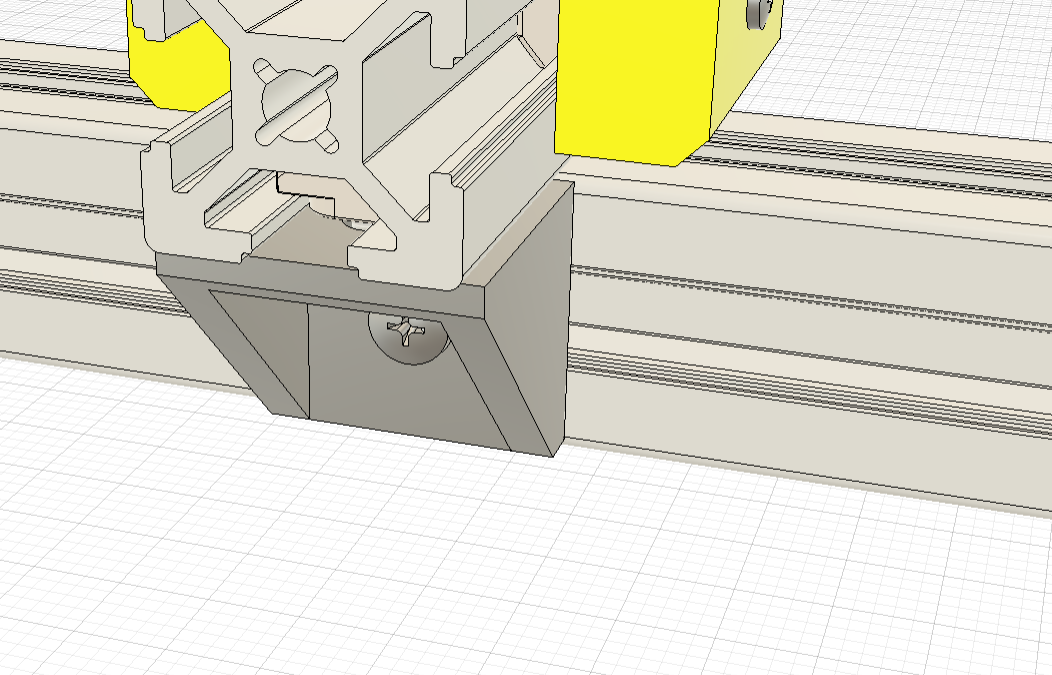

Cad Fixes

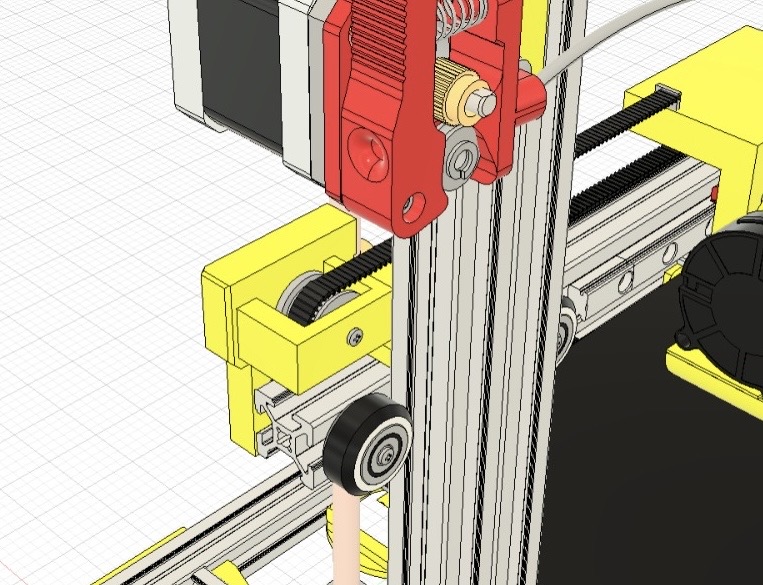

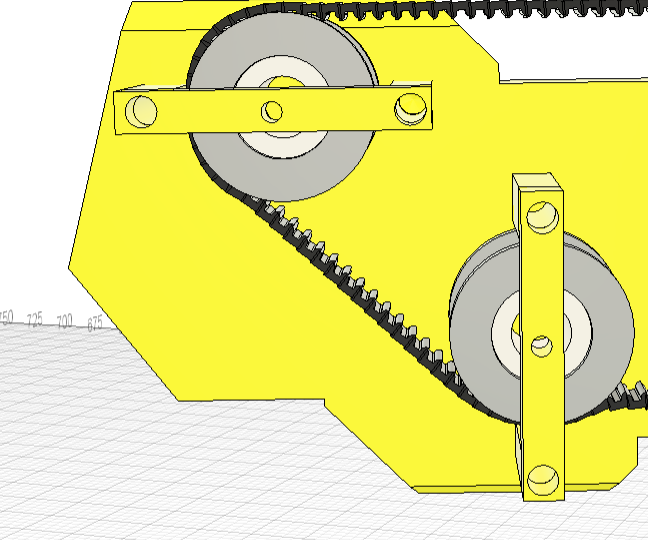

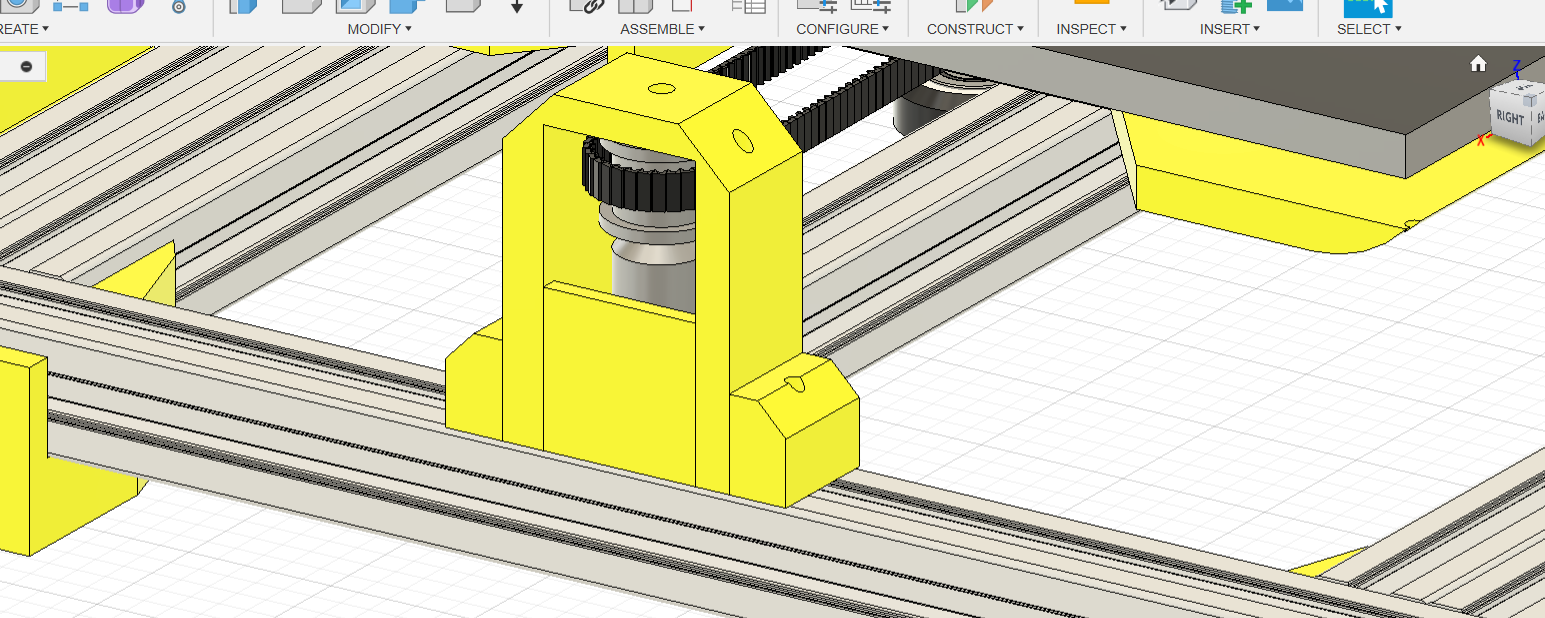

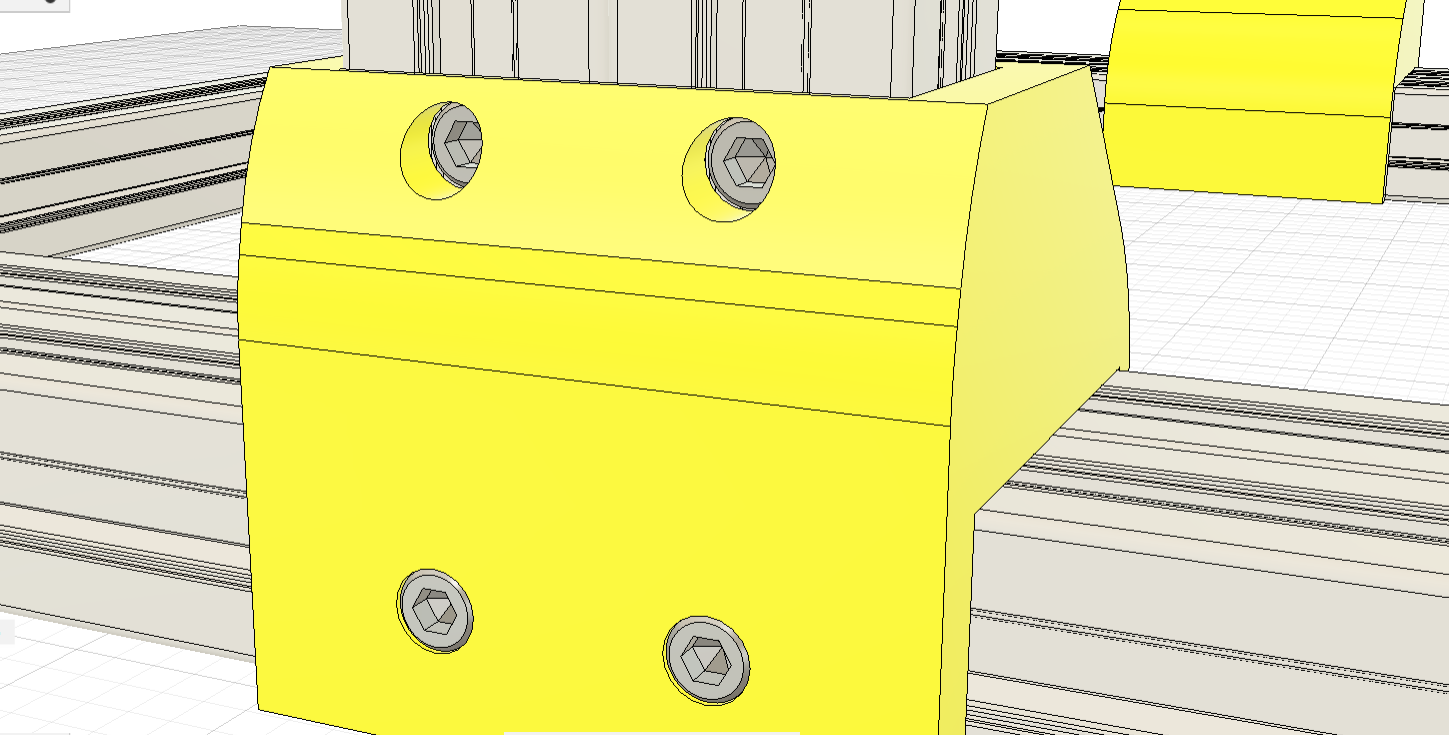

After Reviews from Tanishq and Discord i decided to do these changes which include making the double sheer broader in idelr , changing the position of bowden extruder to side way and updating the design of y axis mount ideler to make it tensionable now

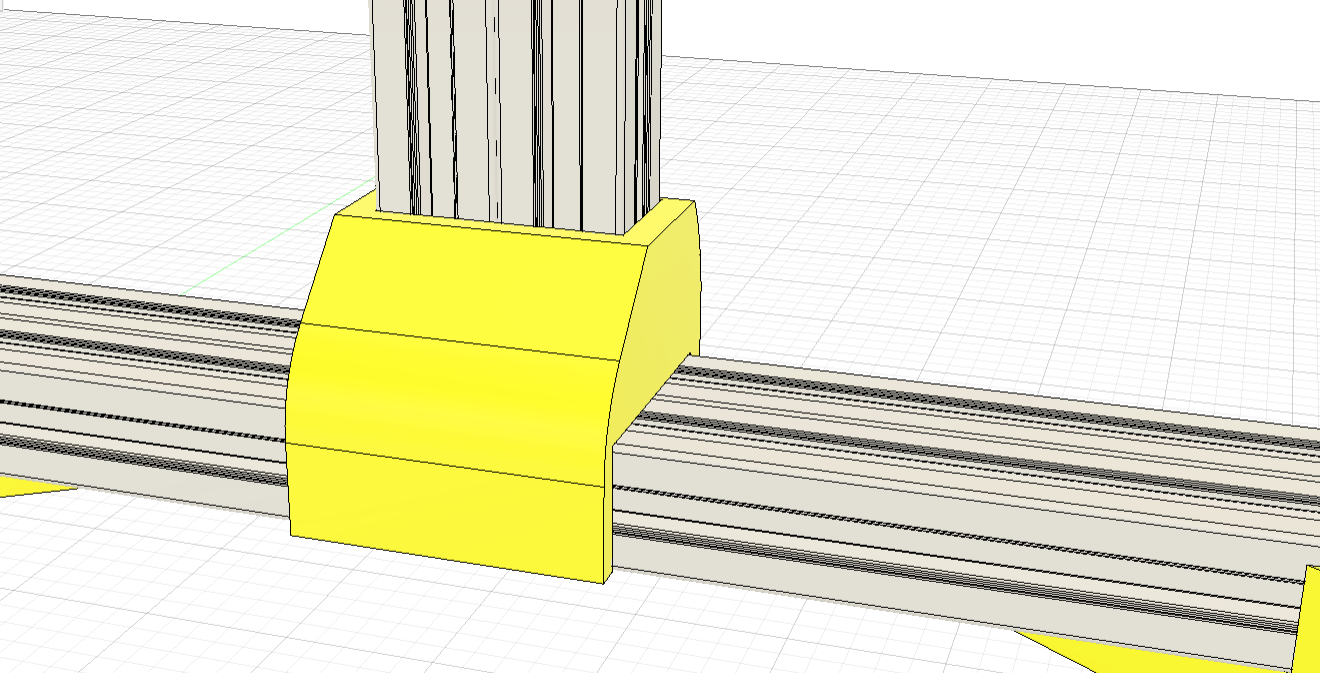

Now Question arise how would i be able to get y and x axis stable so for x axis since i am already having dual z axis motors so there was no need for extra extrusion and wheels with tool head since removing them already removes a large load from gantry thus it give a stable output since it was creating a over joint to the gantry also I decided to keep y axis stable not just by piece of plastic but with some real thing so i got with idea of using these joints

![]() Tanook 🚀

requested changes for MAKZY ago

Tanook 🚀

requested changes for MAKZY ago

1. Your y axis is not tensionable 2. You should make it heated. 3. I dont see how ur y axis belt is tied to the bed 4. no hotend fan mount 5. Duct ratio is too big 6. A lot of the mounting isnt actually mounted. 7. your x axis clips into your z axis extrusion 8 your x axis double shear is very thin 9. Fix the bowden, talked to you abt this in DMs.

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

Some More Changes

.png)

.png)

Ok So i did some changes by updating the motor mount i have added a bottom support so that it could handelthe tension from the belt and doesnt slide also i have added a double sheer supprt to the motors pully , increased the width by more 30 mm and wheels including every right part the benefits from the above changes that will improve overall functionalty and working are:-

- strength against sliding with belt tension boths side

- strength to both motor and idler with double sheer support

- extruder will able to cover whole bed now

- belt will work properly without escaping from the pully with the support provide

I would Like to Thank to all the 3d Printing Discord Community for the real and practical solutions and Tanishq for helping selflessly to improve the design

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

Changed The Belt Path

.png)

.png)

ok so after some more reviews and research i decided to change the belt path of the printer and using the same models and some adjustment i was able to shift it and benfits of the decisions are

- improved motion

- less complexity

- small belt paths as suggested by tanishq

- adjustable tension for the ideler pulley

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

Some More Fixes

.png)

.png)

After some more reviews finally i feel i am done with the changes required , i would thanks tanishq for helping me get better ppl for reviews , so the chnages i made are major and important for the whole functioning i have added 3 wheels instead of 2 for stablity please ignore if you feel linear rail are close to wheels they good amount of space between them also i have increased the width of the whole printer by a major amount for linear rail and bed to have good coordination and also add a double sheer support to the idler with custom design caps

![]() Tanook 🚀

requested changes for MAKZY ago

Tanook 🚀

requested changes for MAKZY ago

discussed this w u, excited to see how it goes :D

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

Issue Fix

.png)

.png)

.png)

.png)

Fixed the belt paths and v slot wheels positions and change the linear rail to less wieght so that it could be practically functional all these changes were made after suggestions from 3d printing dicord channel ,uuh ppl were lit making fun of my belt path saying its cursed but yeah i have changed

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

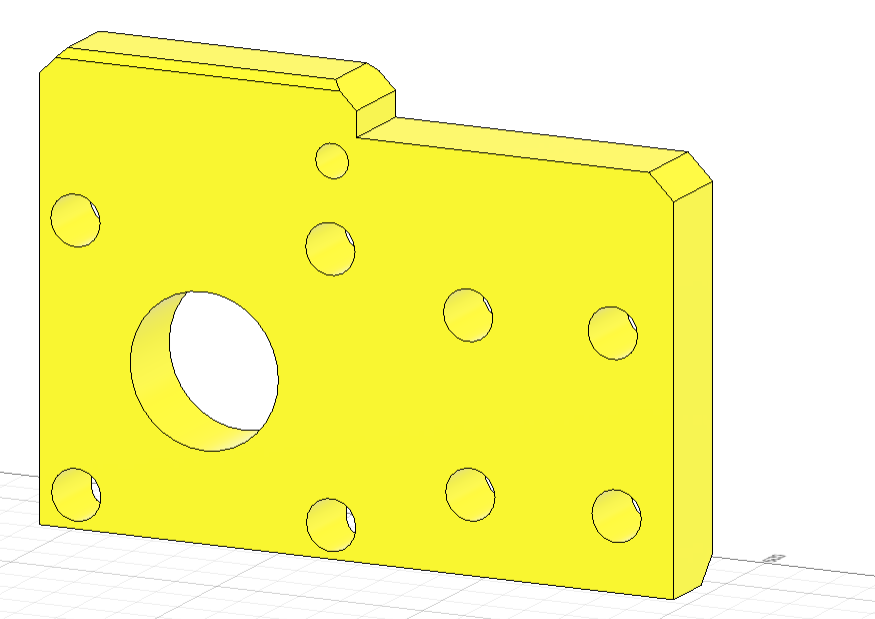

Fixed Some Things

after reviews by Tanishq's review i added some changes to the repo uhh i am so dumb as i used gpt to correct human mistakes like grammer bcz i know i am really bad at typing and just copy pasted it idk i didnt checked it correctly it changed my full sentences (what i wrote originaly) anyways it happens

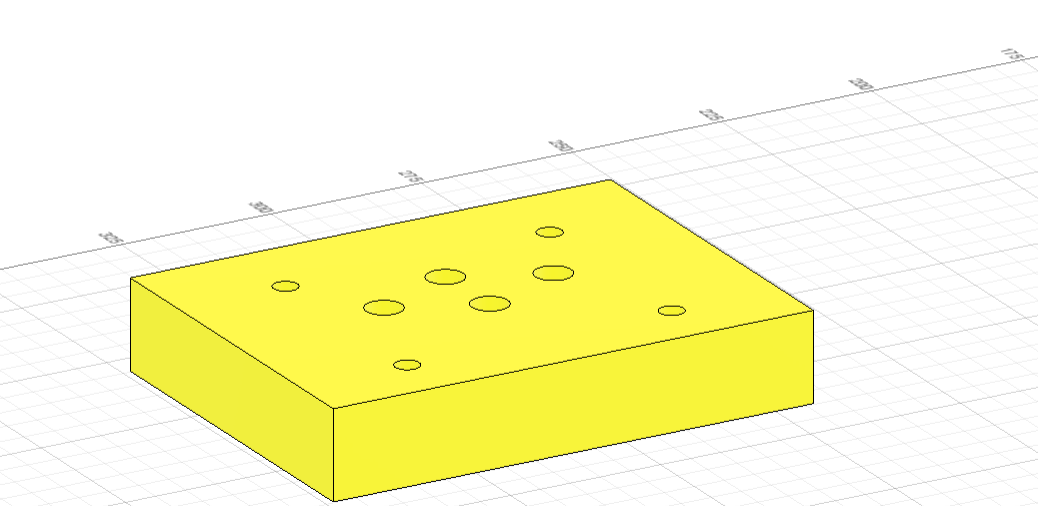

so i correct the mount of the y axis holding pully as it should be double sheered for more strength i took some reviews and help from one of my mate who had build 2-3 printers for our school so yeah he said it would work fine

.png)

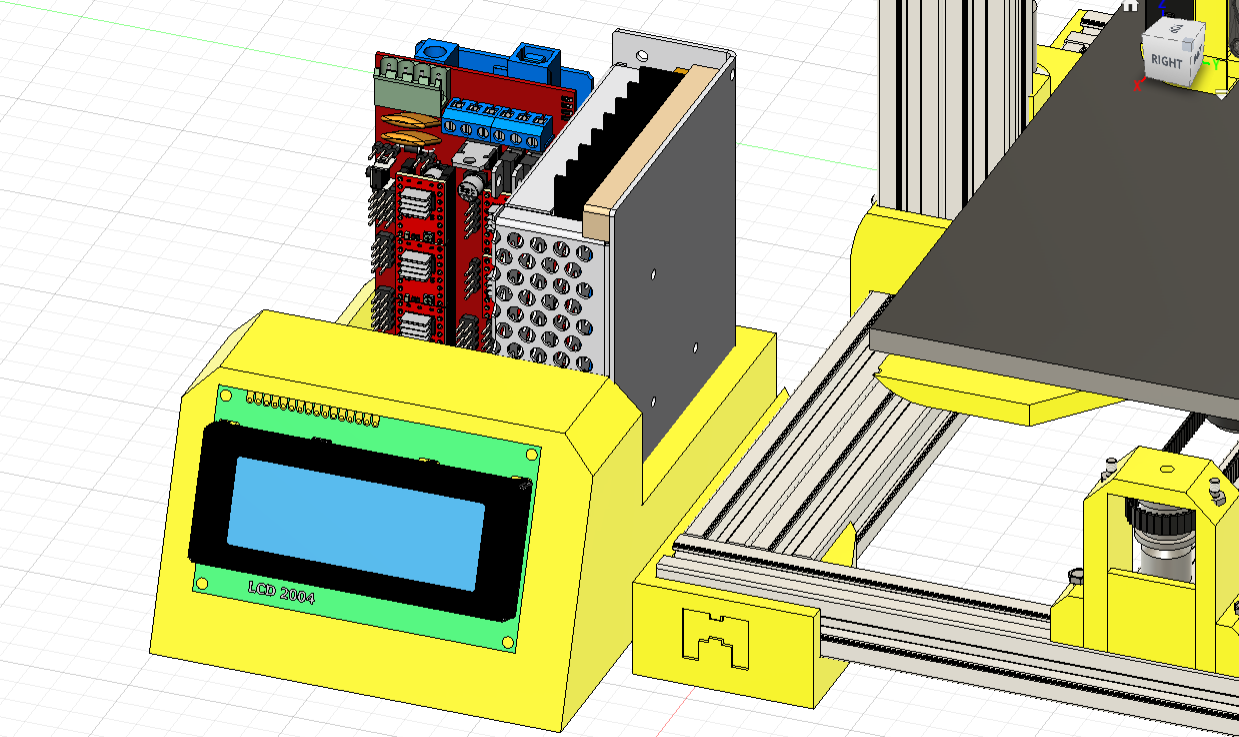

then i add a container and mount for mcu and power supply and a lcd screen and updated the cad model here how it looks .png)

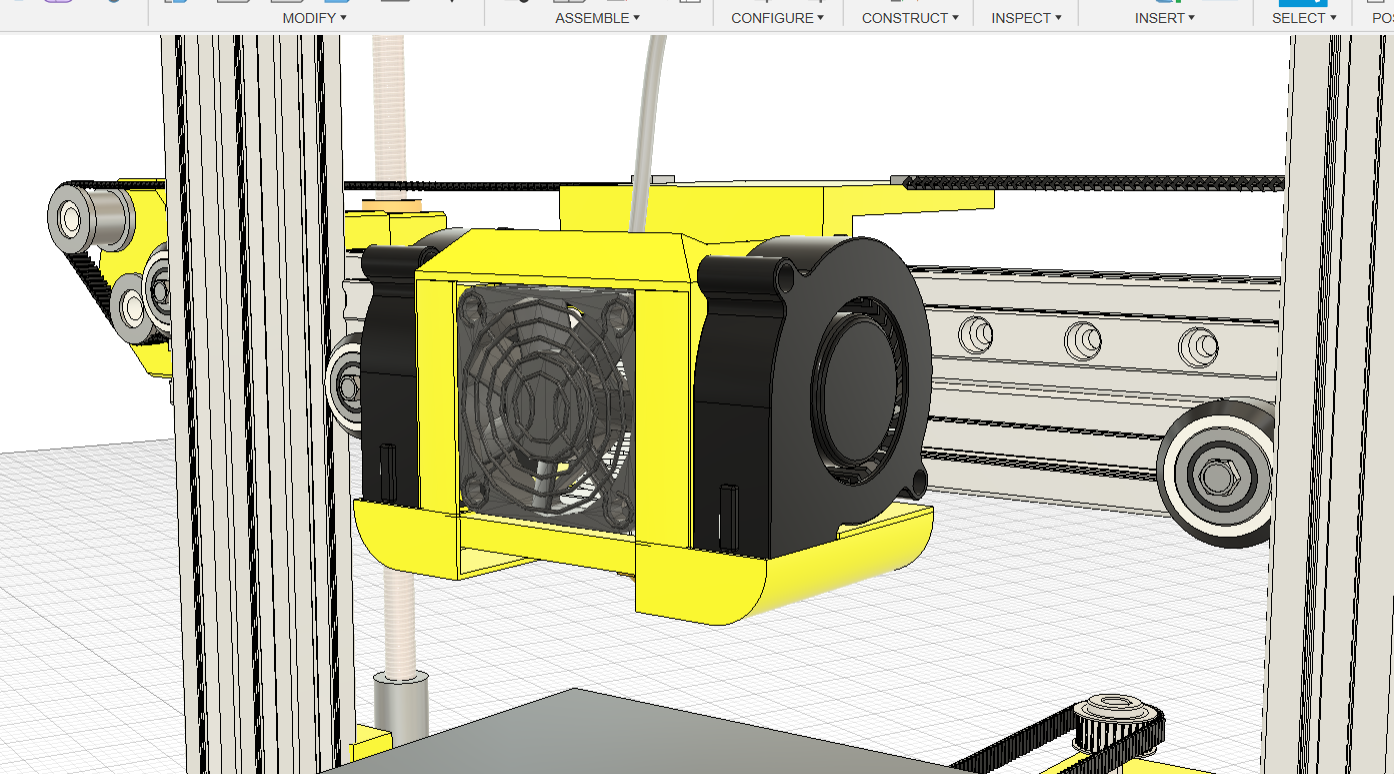

then after that i changed my whole toolhead for more better looks and most important functionality ,added a part cooling structure and shifted to linear guides insted of wheels for more sleek look and performance.png)

![]() Kai Pereira 🚀

requested changes for MAKZY ago

Kai Pereira 🚀

requested changes for MAKZY ago

Please remove ALL the use of AI in your project, and include basic firmware configs!

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() technical_.

requested changes for MAKZY ago

technical_.

requested changes for MAKZY ago

There is not enough complexity to warrant a tier one. You did create a custom frame/housing for parts, which is great for a tier two, but you used only premade modules for your electronics. Optimize your BOM, or improve your project's complexity! In addition in your submission, you only show 8566 rupees, which is around 98 dollars. Fix this price discrepancy, or upload more pictures of your full BOM.

Recommended tier: 2

Grant to expect: $97.57

![]() Amu 🚀

submitted MAKZY for review ago

Amu 🚀

submitted MAKZY for review ago

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

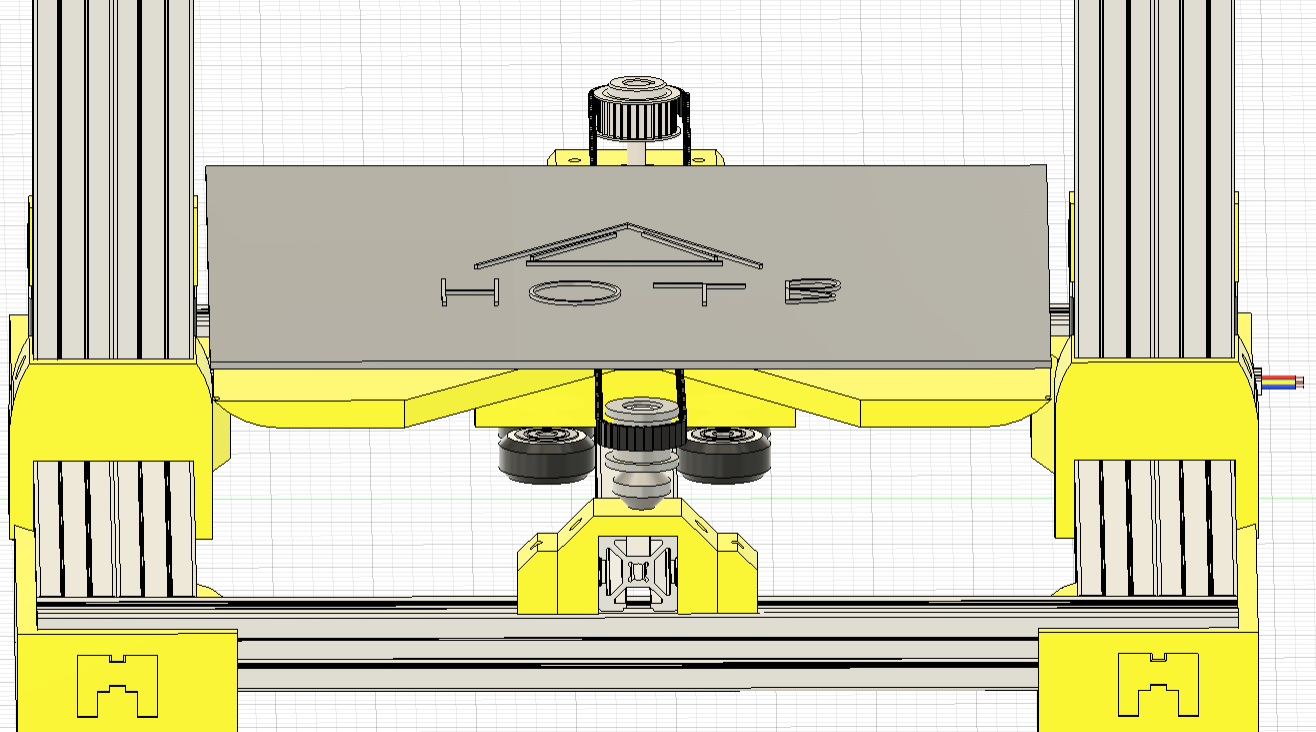

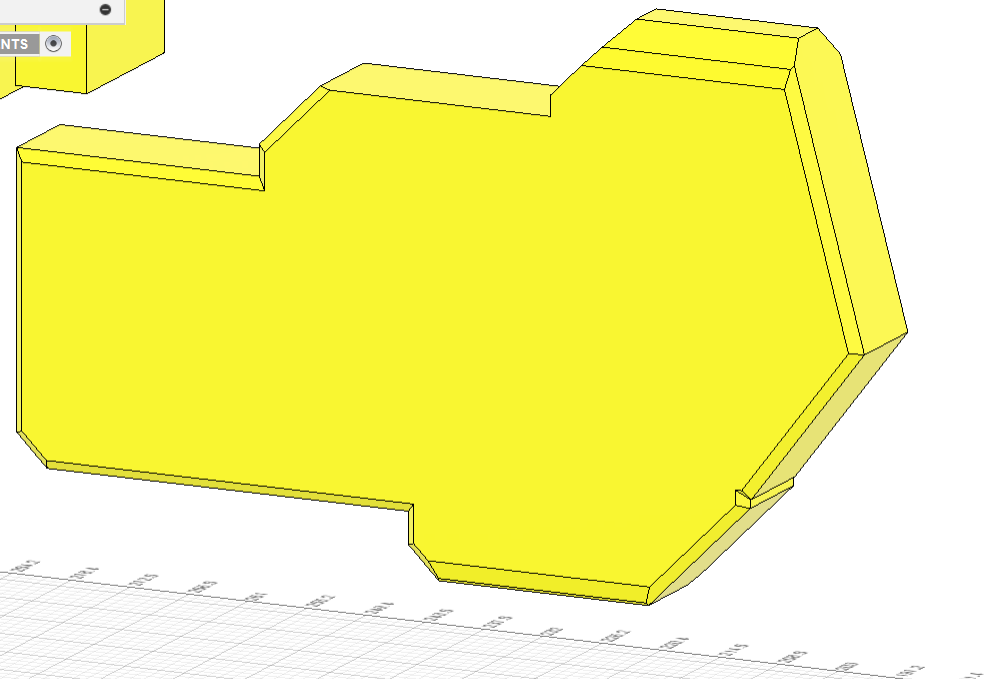

22 Oct (Design Continue)

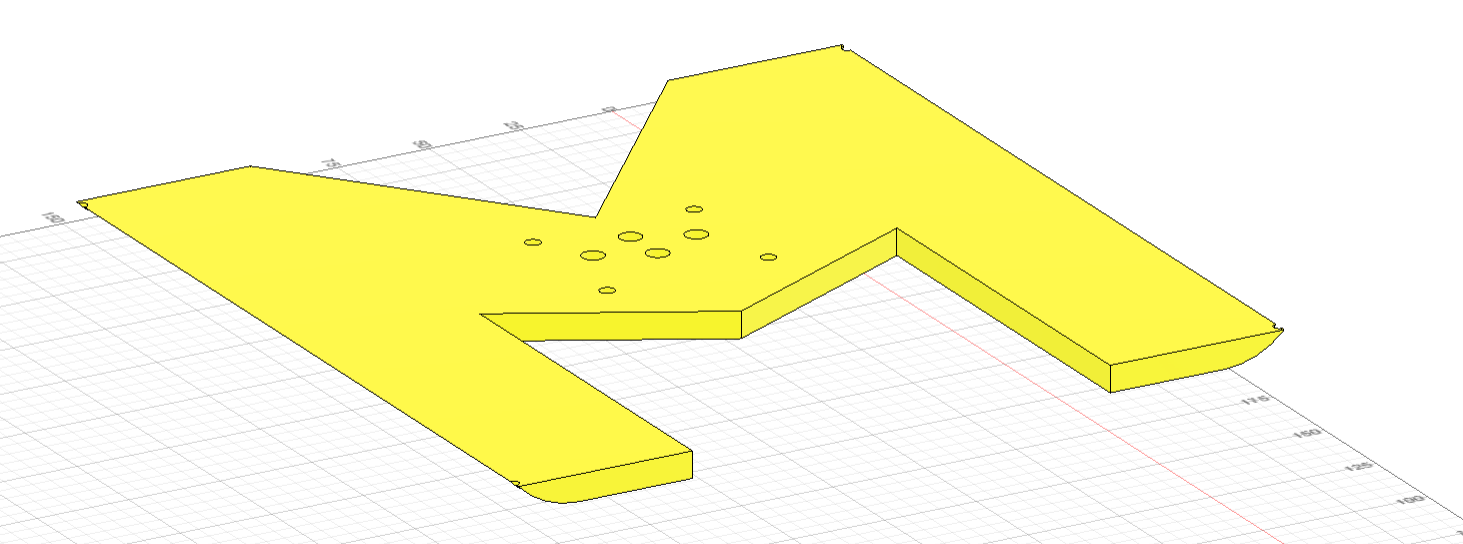

so yesterday i was not able to complete my full model bcz of our traditional festival so yeah today my goal was to make y axis for that i first started with creating a bed holder for hot bed and yeah i decided to make a it m shape but fully functionable it took me 40 min to create a bed holder after sketch on my lap uhh i would def throw this piece of trash after i comp this project

.png)

.png)

after this i created a holder for y axis extrunsion and a mount for motor for this it was a complicate das motor was to be placed stabl nd steady it would screw upto the profile and then a ock system to make it fullt float

.png)

then second side i added a pully to hold the belt and uhh it was time to do the most anoying part of this project the belts i repeated the same staep and tried to add allin once but it took 40 min to fully added and then for athor side which took 24 min ig idk why its talikg to long may be due to my bad ram which i tried to replace for more power and yeah it does but opp ,movng to the belt it took maybe 1-1.5 hour idk the exact time to load and here how it looks like.png)

.png)

hmm after some finishing touches i was able to complete it and yeah see how it looks

.png)

.png)

.png)

.png)

.png)

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

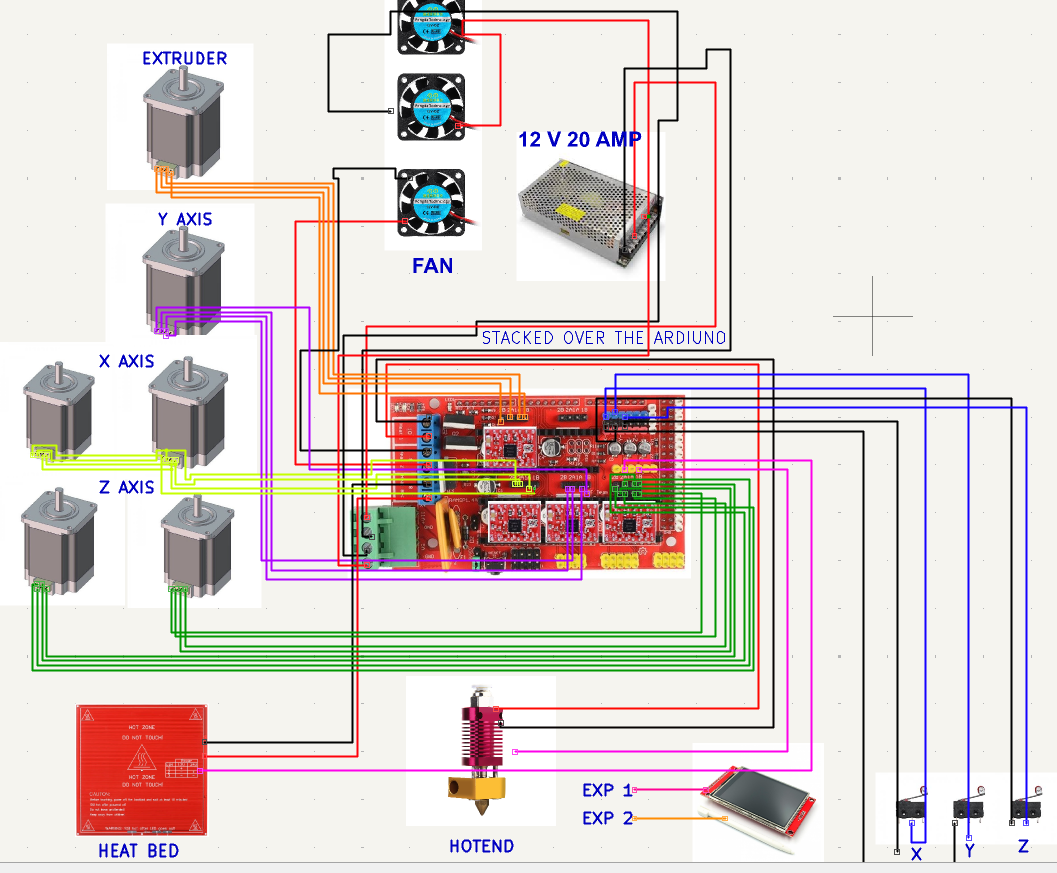

21 Oct Electronics Part

Electronics was a work of 30 min for me as i knew how would i connect wires bcz after a exp of printer which i made ,hmm i would be using marlin and ardiuno and ramps combo for this i have a room for bl touch wiil look to add if i had time so starting with the Motors i connected the and Yaxis motor to the motorpins and then connected two X axis motorin parrallel and then connected to the board next connected Two Z axis Motors to the Board then connected Hot bed and Extruter Thermistors,Then 2 fans With power supply and and 1 for Heatsink ,moving to lcd display i choose a 3.5 inch tft touch diplay a connceted to the EXp1 And Exp2 the connected hotend and heat bed to th board , as There were many thing connected to a single board so the wiring looks very complex but trust me i have assinged diff color to diff wires so try to zoom the pic for more understanding ,tried to make it more cleaner but coudnt i will be using Marlin As Firmware and Will try to create my custom and personalised one in future

.png)

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

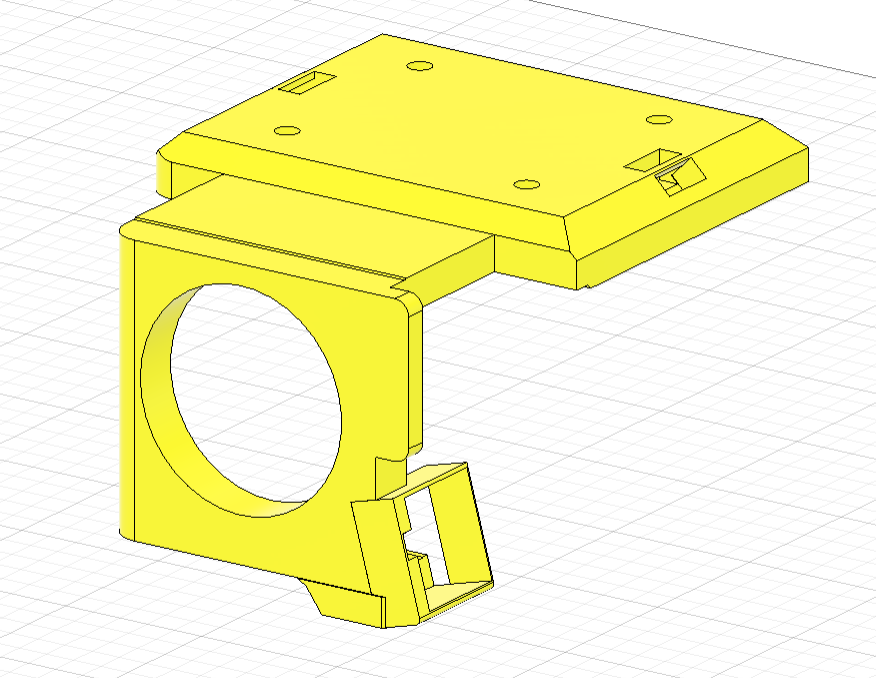

20-Oct (Idea And Design Continue)

uhh i hate typing in my small laptop so i just keep on the journal with writting it physically on my fav notebook this process is same as i did for highway and clutter so yeah please forgive me for late journaling ,

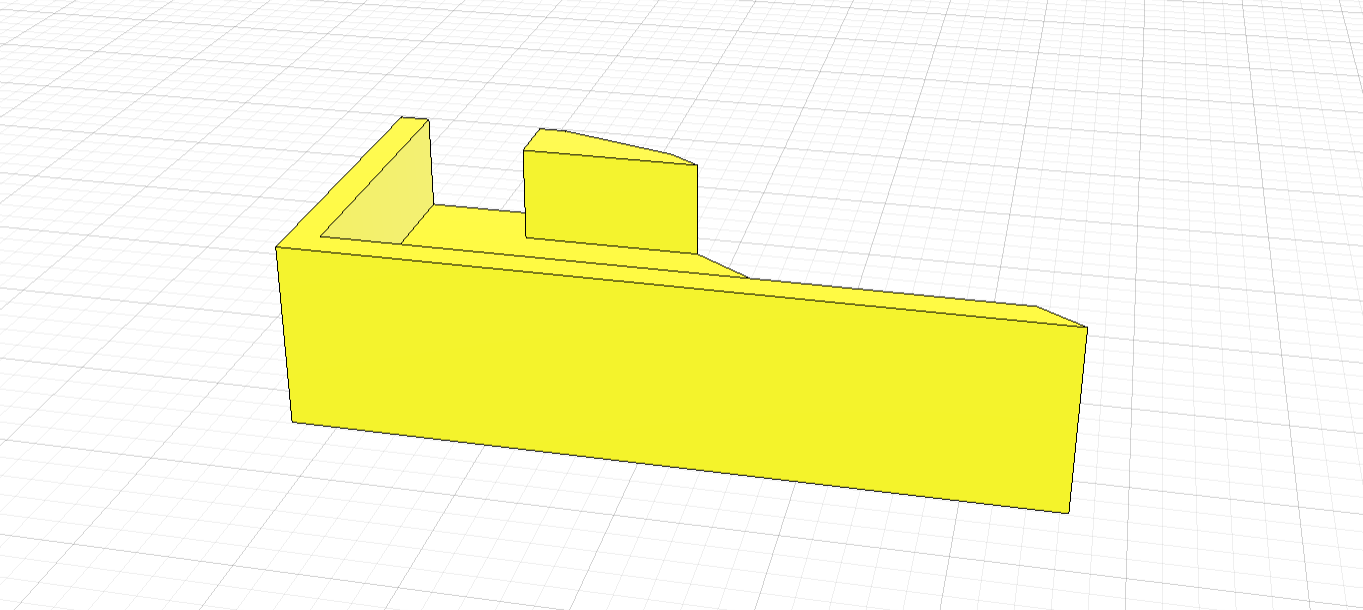

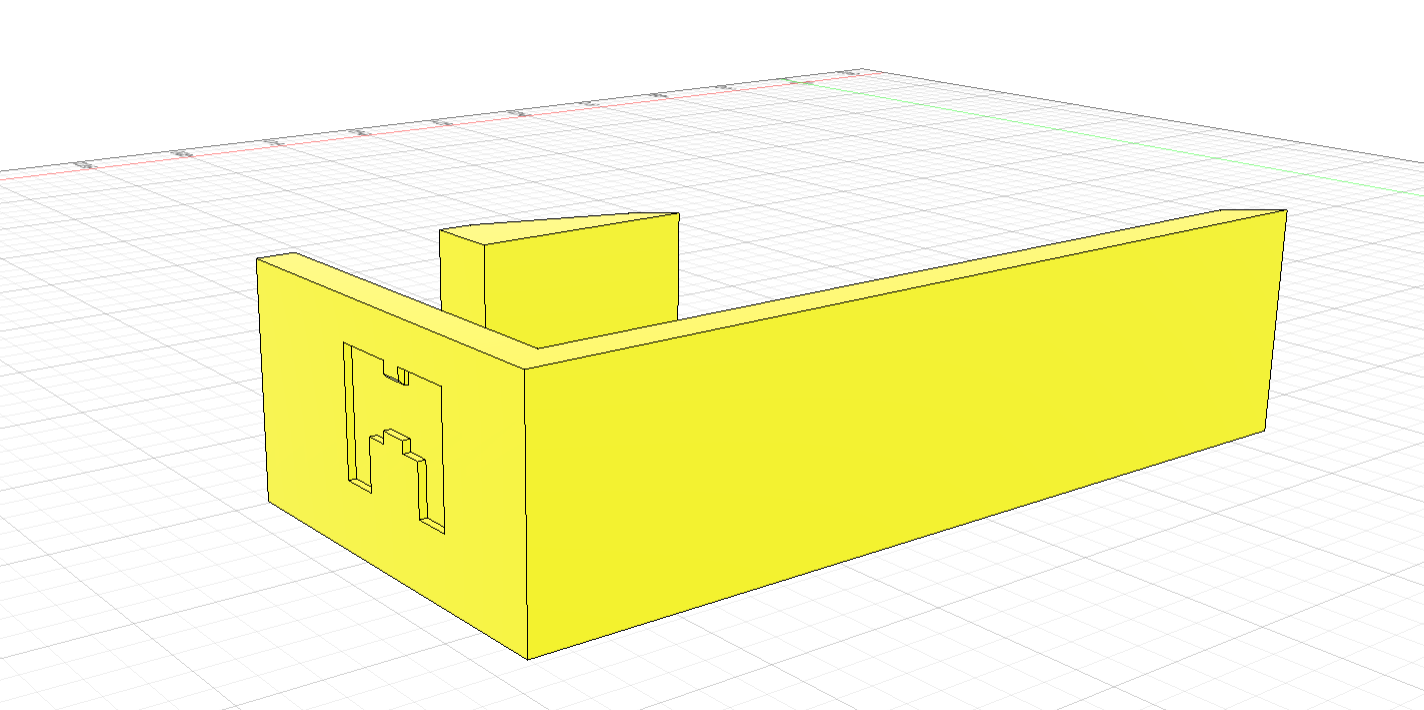

(8am-9am ,20 oct )

so today i decided to complete gantry and for that i would need holder for motor on one side and another side for pully hmm so after making many diff styles a perfect look was not coming so saw many printers and decided to make now as i wanted to to be functionally good and lookwise also so here what i made

.png)

.png)

(10am-1am ,20 oct )

after that i started making toolhead holder for the printer it would look good as well as practical because the toolhead of TOYZY is very heavy so i decide to add only one fan uff challenges occur again my laptop is running very slow the thing which req to make is taking more time than need ,hmm nvm i will do everything for this printer ,and add a slot for fan to placed vertically and a hole for the fan to cool hot end , for this printer i looking to use same e3d hot end ,i let the other side open for wires hmm also it will be moving on the wheels and aluminium extrunsion her it how it looks like all this i will be add to the main model for a final look of the day

.png)

hmm after a 10 min break i decided to add belts to it the uhh it really took me half and hour to set it up along the line because my lap was not able the handle the load i used patteren along path to make the bellt it took 30 min to render a belt for one side and after 2 hour i was able to complete the belt and yeah fter 3o min i fully setuped the gantry here it looks

.png)

![]() Amu 🚀

added to the journal ago

Amu 🚀

added to the journal ago

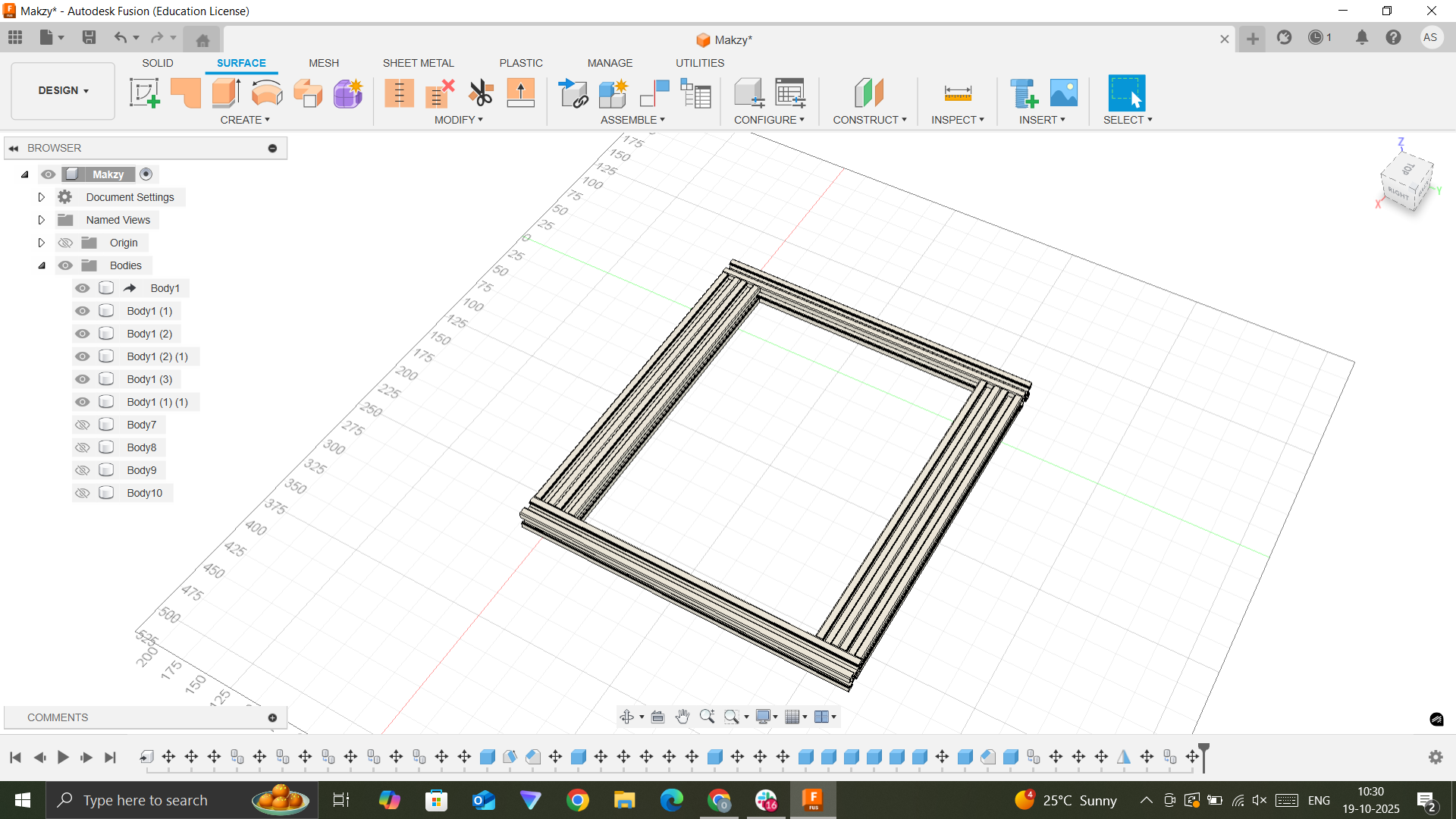

19-Oct (Idea And Design)

(7AM-8AM)

The day when MAKZY was just a rough idea, Learned about how i can get more to CAD models and printers and realised i would need a companion for TOYZY , it will work on Ardiuno Mega and Ramp shield ,the Idea of this type 3D printer is not just one day thought it was my next target after highway but was not able to get started ,and was it was left ,thus got to that page where my idea could implemented ,so that was the story behind building this project

(10am-10:40)

thus as it was off from my school so i decided to do lot o work today itself so firts i created a basic structure of the printer in Fusion360

.png)

(11am-2PM)

after that it required to place on a stand so it took me a hour to create a perfect and unique stand for the printer as its my second time of a complex cad modeling which required a proper measurement so it was taking a lot of time

.png)

.png)

.png)

Now it was time to create add vertical extrunsions so i created a mount for it and it was the hardest part because if it go wrong whole printer would not work properly so i created a mount and holes for it !.png)

.png)

After that i realised that the orientation of the extrunsion was not good for the printer mechanics so quickly update the mount and positon of the rods to get to right position.png)

after this i add wheels and mount for nema motors .png)

.png)

.png)

![]() Amu 🚀

started MAKZY ago

Amu 🚀

started MAKZY ago