Timeline

![]() Rohit

added to the journal ago

Rohit

added to the journal ago

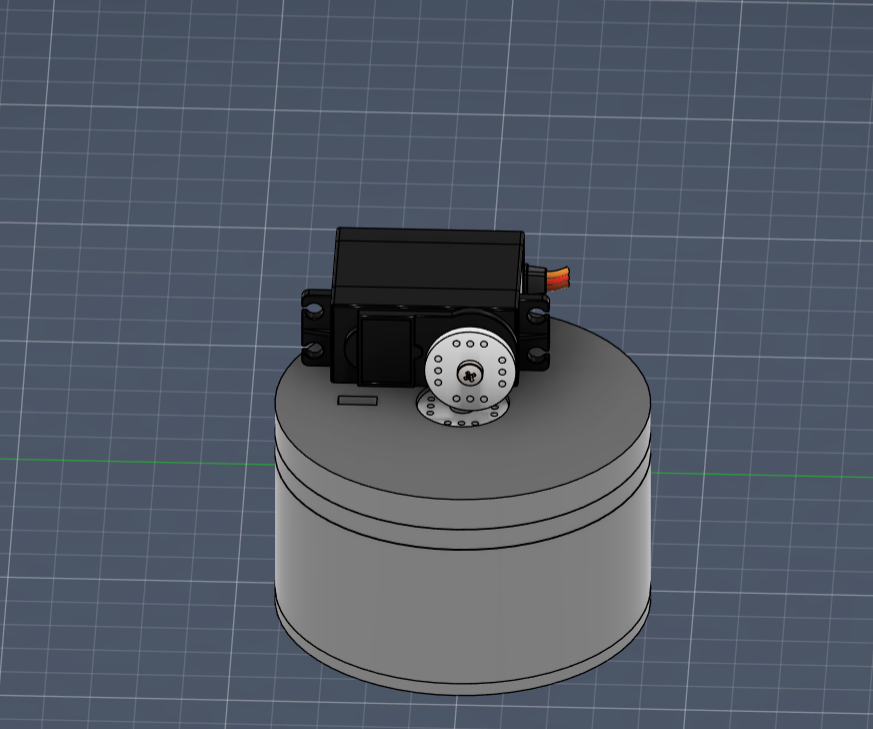

roboarm's base six-sided, balanced.

I began working on the robot's base, which I assumed would be a cool component. It was much more annoying than I had anticipated. I continued experimenting with various shapes, including squares, triangles, and even an odd polygon, but none of them really blended in with the bot's overall design. Each shape either looked totally out of place or interfered with the wheel positioning. I had a "duh" moment after several unsuccessful attempts and a lot of intense screen staring. I now know why the circular base is the original and most likely the best option.The design simply... functions. It provides nice symmetry, fluid movement, and doesn't struggle with CAD like other designs do. So, yes, I went classic instead of using all the strange shapes. It is now prepared for a proper render after I cleaned it up and added my mounting points. Although it may have taken longer than anticipated, I'm quite pleased with the final base.

![]() Rohit

added to the journal ago

Rohit

added to the journal ago

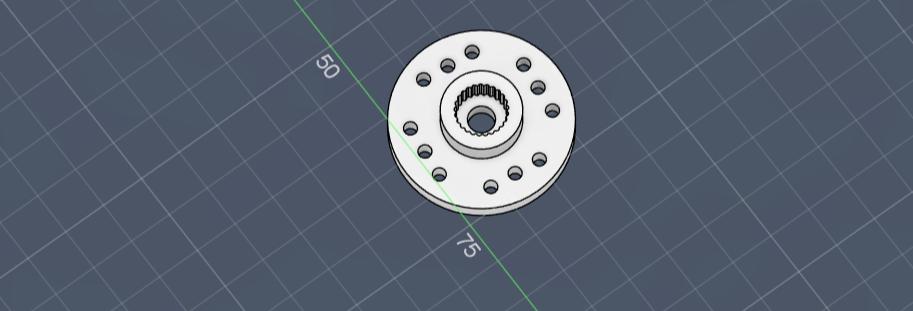

That disc finally aligned with the shaft

So, today was a total mess. I began making the disc for the motors, which is basically the part that connects the robot's chassis to the motor shaft. It should have been easy, but it wasn't. Fusion 360 chose to be dramatic. My constraints kept messing up, the geometry wouldn't line up, and everything just seemed wrong. I got so mad after an hour of trying to fix it that I just deleted everything and started over. To be honest, it was for the best. I was finally getting somewhere. until I somehow deleted the STEP file for the disc model by mistake. Also, I had emptied the recycle bin earlier, which was smart of me. I briefly believed I had lost everything. However, it turned out that I had already imported it into Fusion, so I wasn't totally lost. That little heart attack was still unpleasant. For such a basic component, the disc required a surprisingly high amount of work, but since it serves as the actual basis for the bot's movement, it had to be sturdy.

![]() Rohit

added to the journal ago

Rohit

added to the journal ago

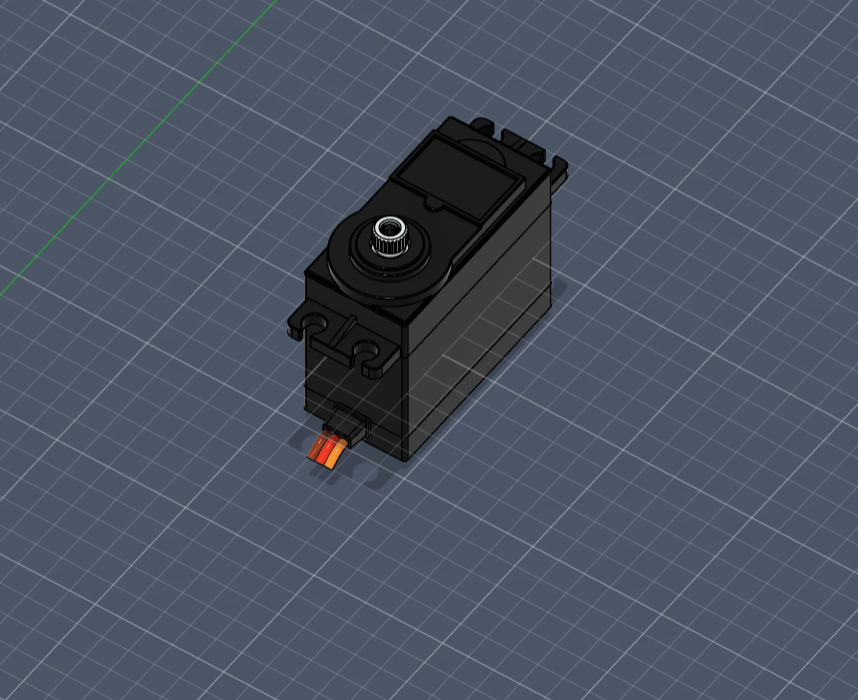

MG996R Servo Motors i finally settled on. Decent torque.

So, I spent the early hours of my day completely immersed in servo and stepper motor charts. I won't lie, it was a lot. I looked at more than 30 different sources, including YouTube videos, Reddit threads, very niche forums, and a lot of datasheets that were honestly way too complicated. At that point, I was pretty much on a mission.

After hours of looking at specs and going down random internet rabbit holes, I finally decided on the motors I wanted to use. The one I chose can handle about 9.4 kg/cm of torque, which is more than enough for what I'm making right now. But this whole thing did take a lot of work, which was surprising. It seems like a small choice on paper, but it took me all morning to figure it out through trial and error and brain fog. I might change the motor setup later, but for now, this works great. Putting a picture of the motor below for context.

![]() Rohit

started roboarm ago

Rohit

started roboarm ago